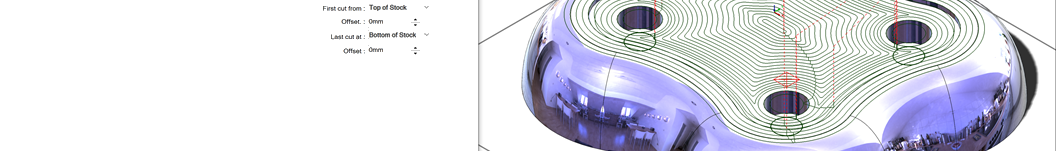

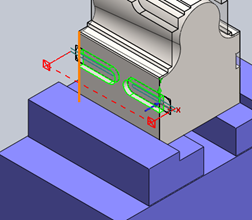

How to Choose Operations for Quicker and More Accurate 3 Axis Programming in CAMWorks

3 Axis milling is the process of milling a part in X, Y and Z directions, and the tool motion is along 1, 2 or 3 Axes simultaneously. It is usually a quick and simple process in CAMWorks. The main advantage

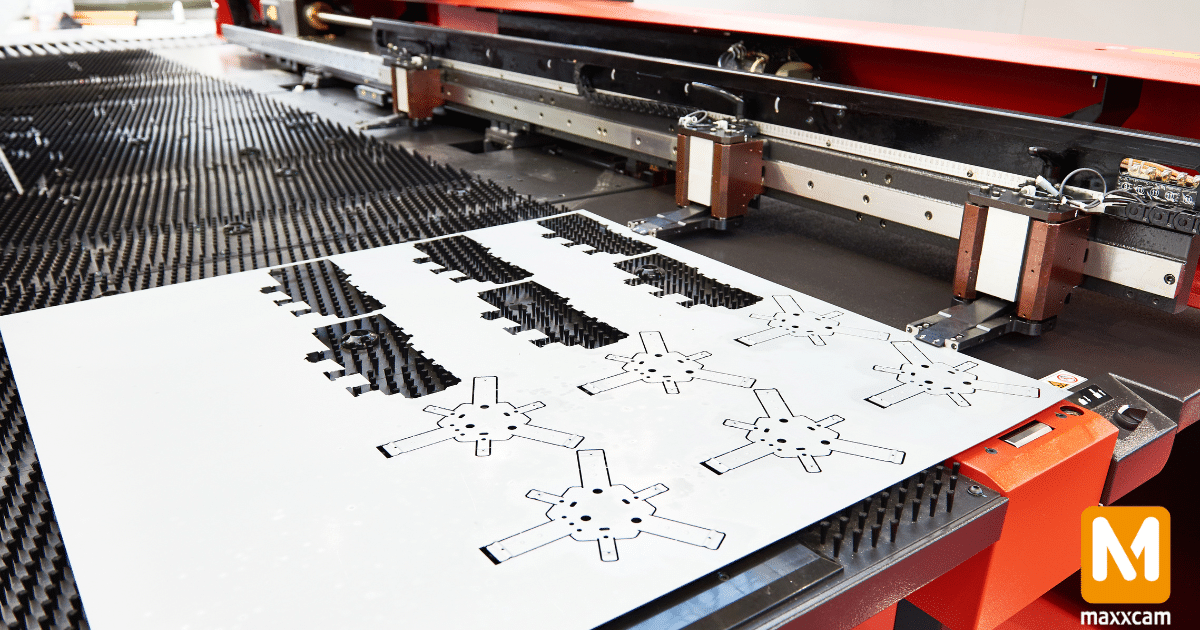

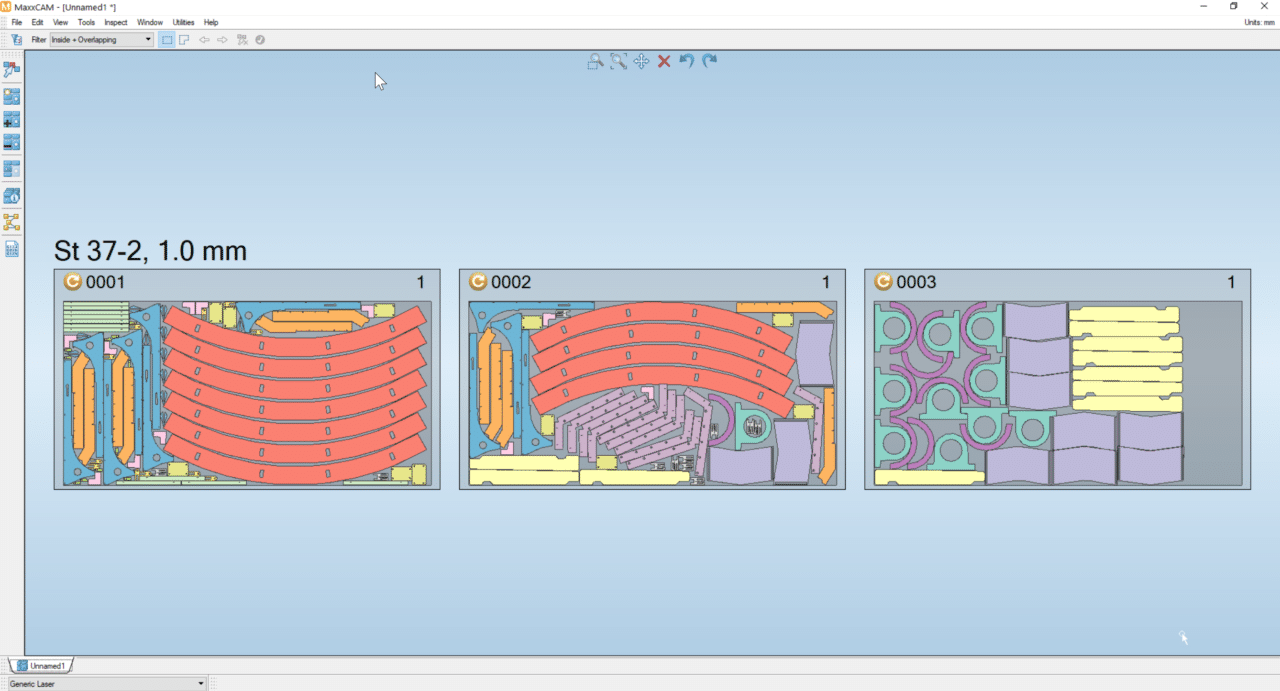

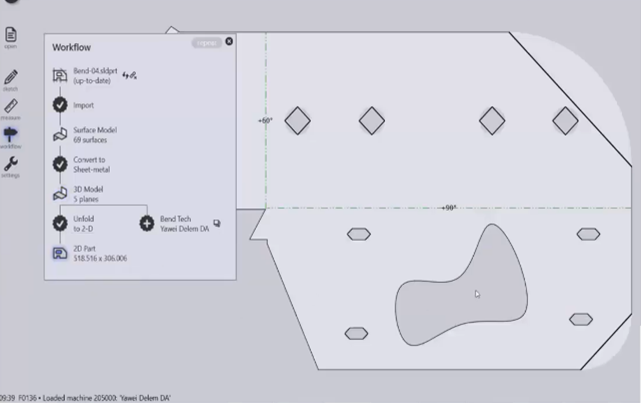

MaxxCAM for optimised Sheet-metal CAM programming

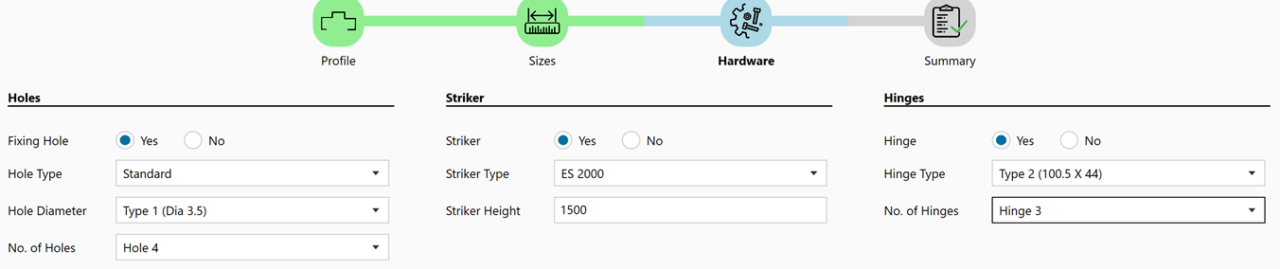

MaxxCAM for optimised Sheet-metal CAM Are you searching for an optimized and time-saving sheet metal CAM software? MaxxCAM is a comprehensive sheet metal CAM software that offers various features, including turret punch, laser cutting, nesting, and more. Let's delve into MaxxCAM's punching capabilities. MaxxCAM

Program your Laser cutting in MaxxCAM Software

MaxxCAM has a comprehensive solution to cater to your laser-cutting needs.( FYI Metacam is trademark owned by We sell MaxxCAM not to be confused we know there are lot of dog lovers out there who get confused with metacam and

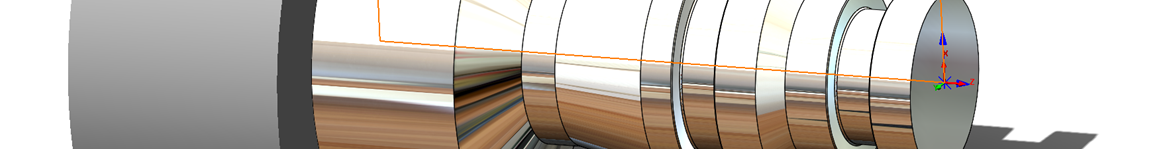

Automatic Feature Recognition For Turning-CAMWorks

Programming for a lathe turning becomes easy and quick when you have CAMWorks. CAMWorks 2 and 4 Axis Turning includes automatic roughing, finishing, grooving, threading, cutoff, and single point (drilling, boring, reaming, and tapping) cycles. CAMWorks turning can be preferred when you need a

Make your User-defined CAMWorks Database

The intelligence behind CAMWorks machining automation is the Technology Database (TechDB). The Technology Database is shipped with data that is considered generally applicable to most machining environments. To gain full advantage of CAMWorks, you will want to modify this data

Simplify the Shopfloor Collaboration Process

CAMWorks ShopFloor is a newly introduced application in the CAMWorks suite of software products. It serves as a collaboration tool between CAM Programmers (who use the CAMWorks application to generate CAM data for part models and/or assemblies to be machined)

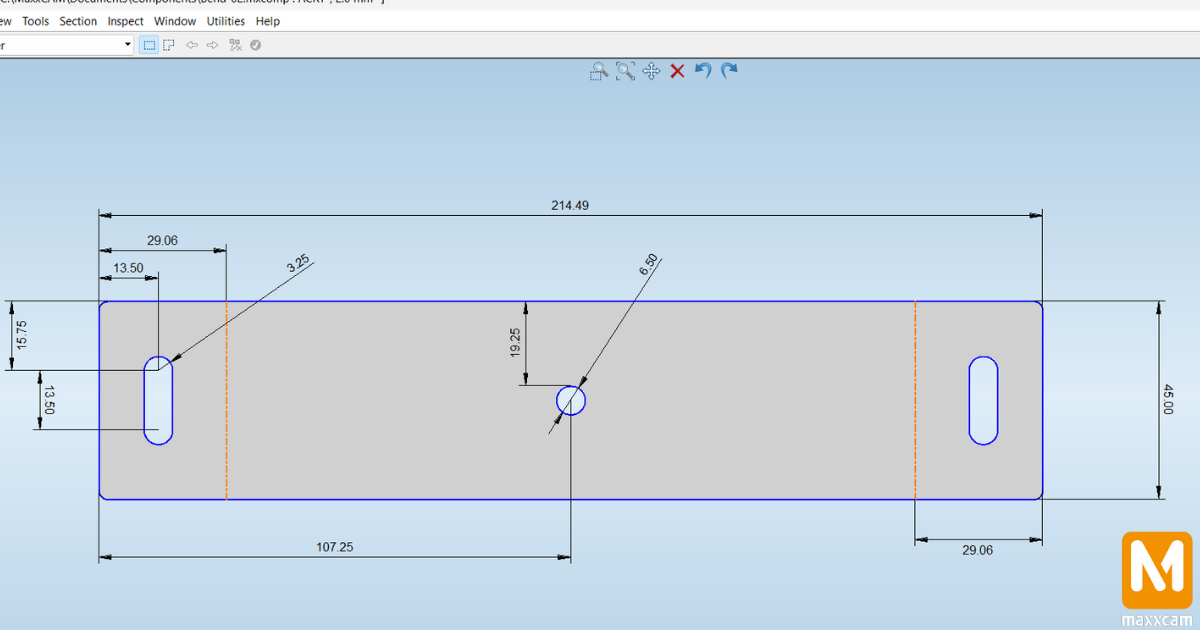

Shorten the Process using MaxxCAM 2D CAD

MaxxCAM's parametric 2D CAD functionality is a powerful feature that empowers users to create and modify designs with ease and precision. This innovative tool within the MaxxCAM software suite streamlines the design process, allowing users to quickly generate accurate and

Use CAMWorks Probing for Accurate Results in a short time

Probing has become an established best practice for maximizing the efficiency, quality, capability, and accuracy of machine tools. Standard routines built into modern CNC controls simplify the integration of probing cycles into machining operations. Machine tool probing potentially makes sense

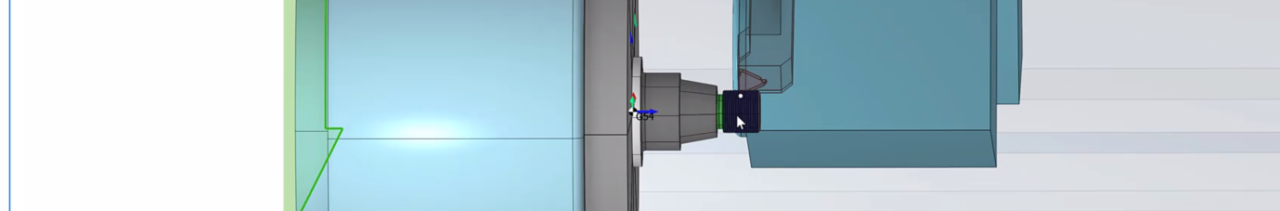

SprutCAM – Cost-effective and powerful solution for CNC programming

SprutCAM is a new-generation software program that works directly with the imported CAD data; it automatically calculates and generates an efficient toolpath for machining a model that can be graphically simulated to allow the user to check the machining parameters.

SprutCAM helps you save unnecessary programming time

Today’s industries are looking for the quickest and optimal CNC programming application to improve productivity. SprutCAM is arguably the ideal solution for that purpose. Even though the SprutCAM has a lot of time-saving features, we can still make use of