Automatic Feature Recognition For Turning-CAMWorks

Programming for a lathe turning becomes easy and quick when you have CAMWorks.

CAMWorks 2 and 4 Axis Turning includes automatic roughing, finishing, grooving, threading, cutoff, and single point (drilling, boring, reaming, and tapping) cycles.

CAMWorks turning can be preferred when you need a quick and error-free cutting.

The programming process is simple

- Define the machine, and stock

- Define the features

- Generate plan and toolpath

- Simulate and generate NC code

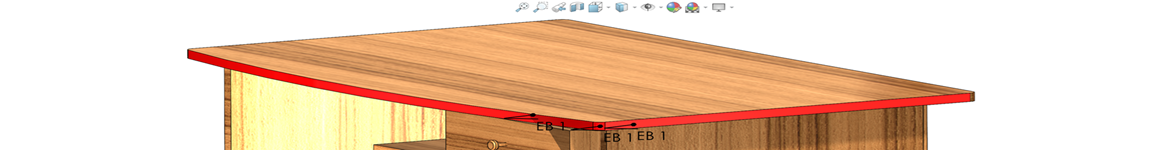

Machine and stock definition

For the turning process, the type of turn machine is selected based on the part. The machine definition includes tool crib, post-processor, chuck/fixture, and setup.

And the stock is defined as per the requirements.

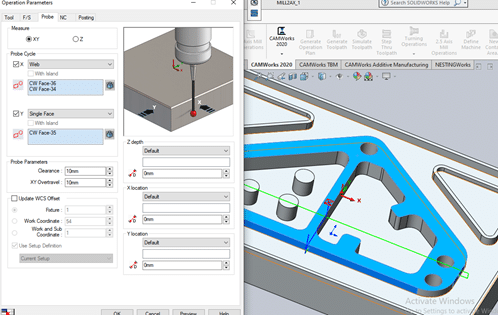

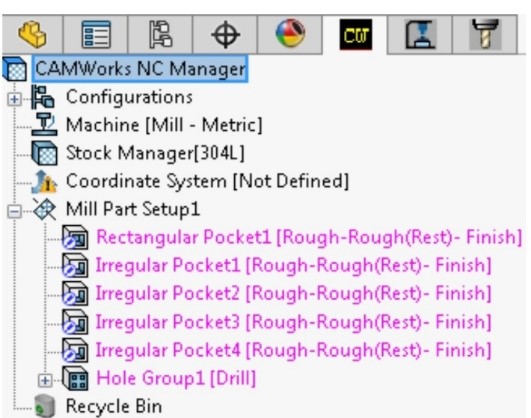

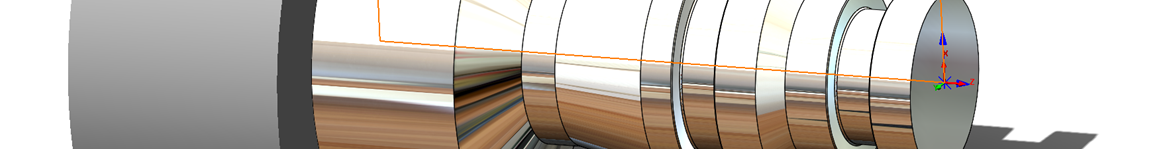

Defining Features

Once the machine and stock are defined, extract the machinable features by using either AFR (Automatic feature recognition) or IFR (Interactive feature recognition) or both, as per the requirements.

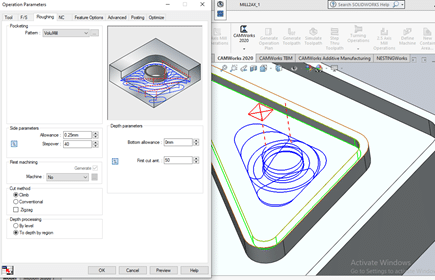

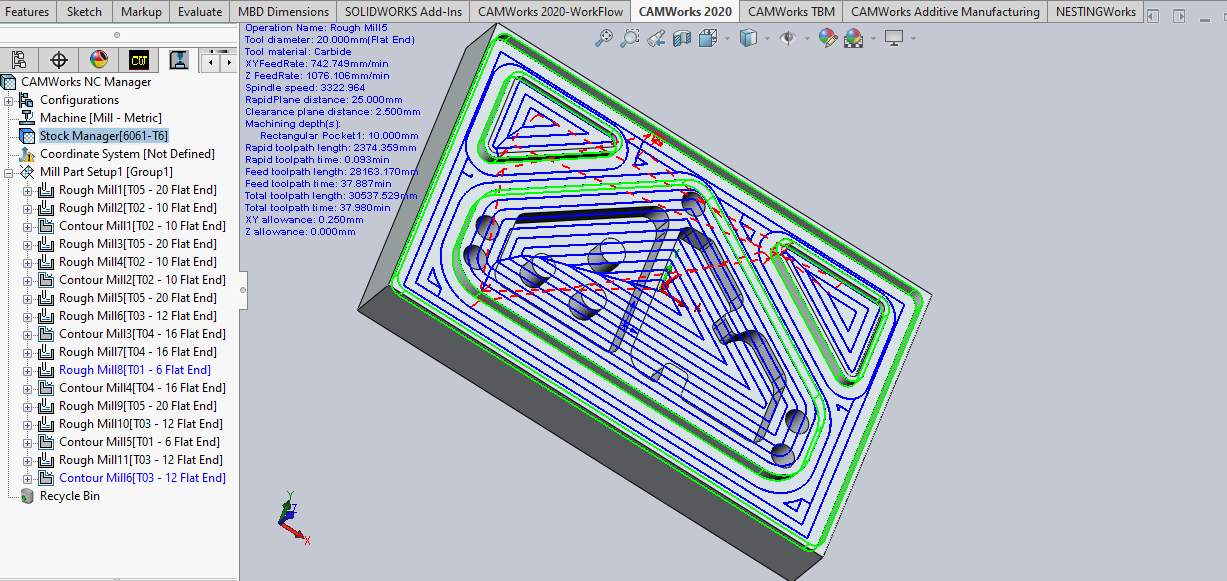

Generate Plan and Toolpath

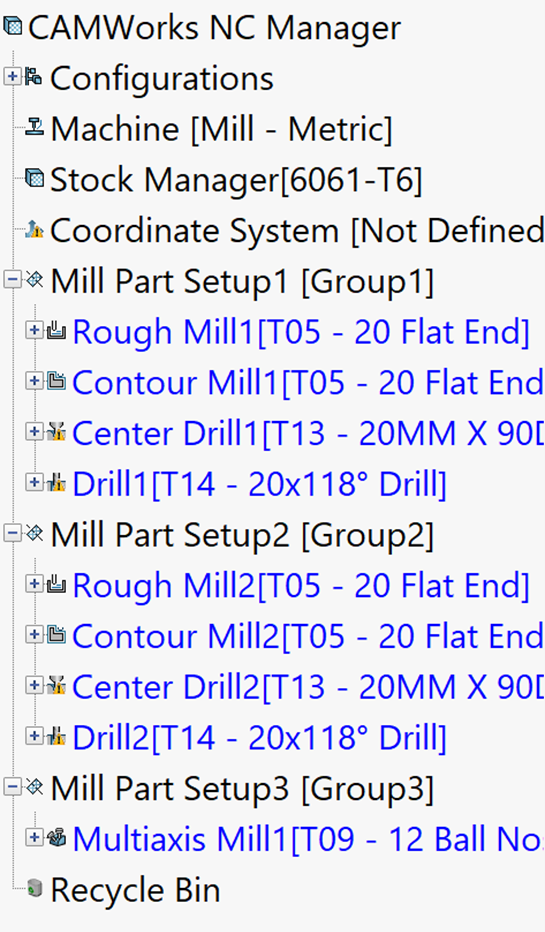

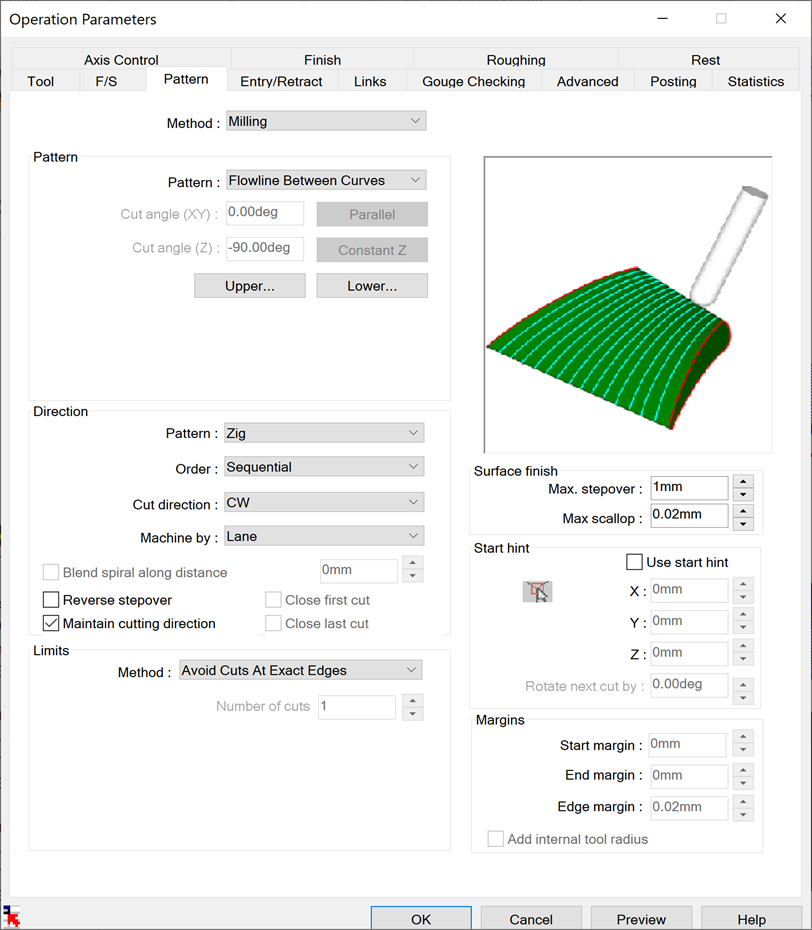

After defining the features, generate the operational plan. Edit the operations or operational parameters if needed and generate the toolpath.

Simulate and Generate NC code

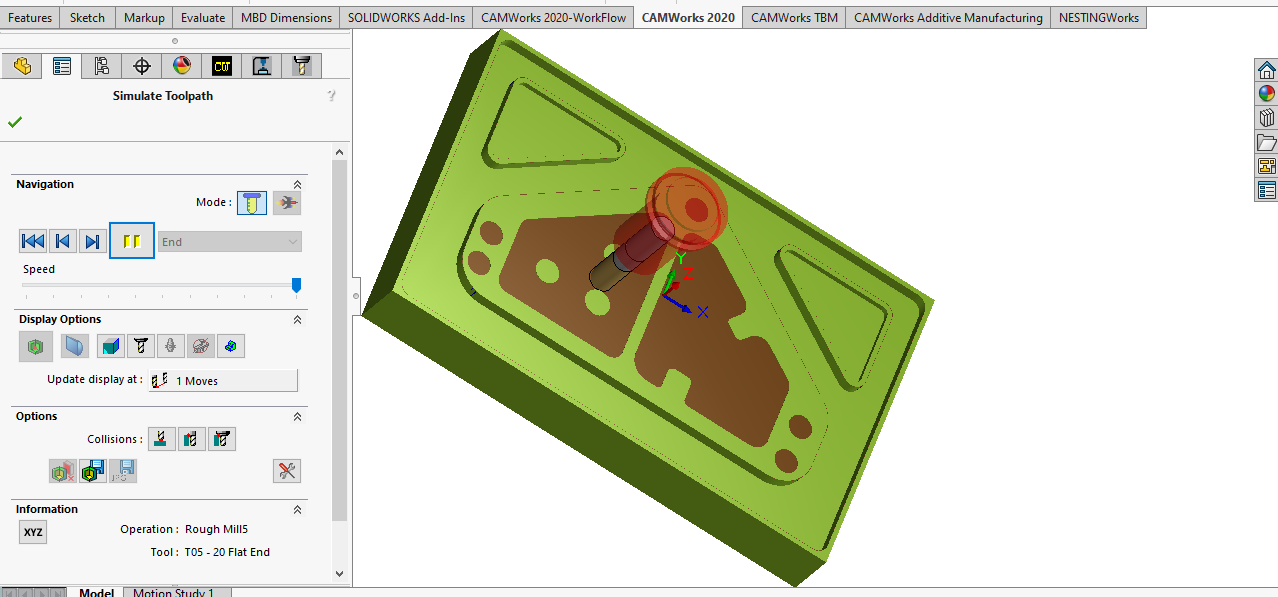

Once the toolpaths are generated, simulate the toolpaths to check that everything seems to be correct.

Then generate NC code and import it to the CNC lathe machines.

Though CAMWorks is user-friendly and self-explanatory, we are here to help should you require assistance.

For more information on CAMWorks Software and product enquiries visit us at http://www.nctools.com.au/or call us on +61 3 8618 6884.