CAMWorks B Axis Functionality for Machining Turn Finish Operations

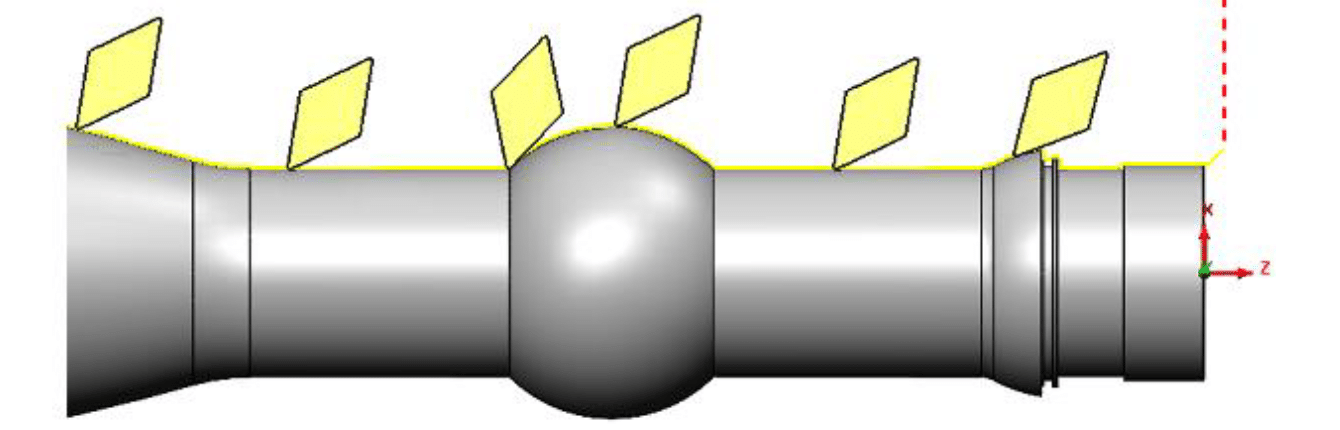

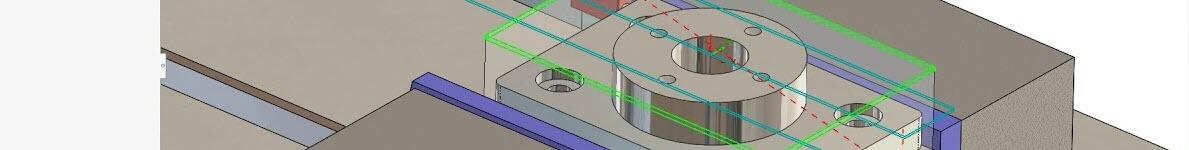

Introducing CAMWorks Continuous B Axis Functionality for Machining Turn Finish Operations

The advantage of this Continuous B Axis Turning functionality is that users can machine the Turn/Mill-Turn part models with a lesser number of setups. In CAMWorks 2020 SP3 version, this functionality will be available for Turn Finish operations.

Types of Cut for the Turn Toolpath when Continuous B Axis Functionality is used

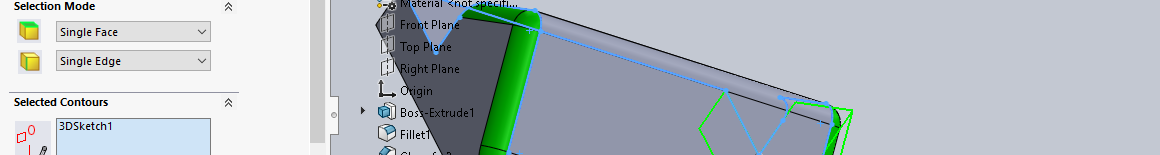

Use the options available within Type group box of the Continuous B Axis Settings dialog box to define the type of cut for the Turn toolpath.

Constant Angle

When this option is selected, the Turn tool will remain at the effective lead angle. The tool will tilt only while cutting the undercut areas. This will result in lesser number of tool rotations

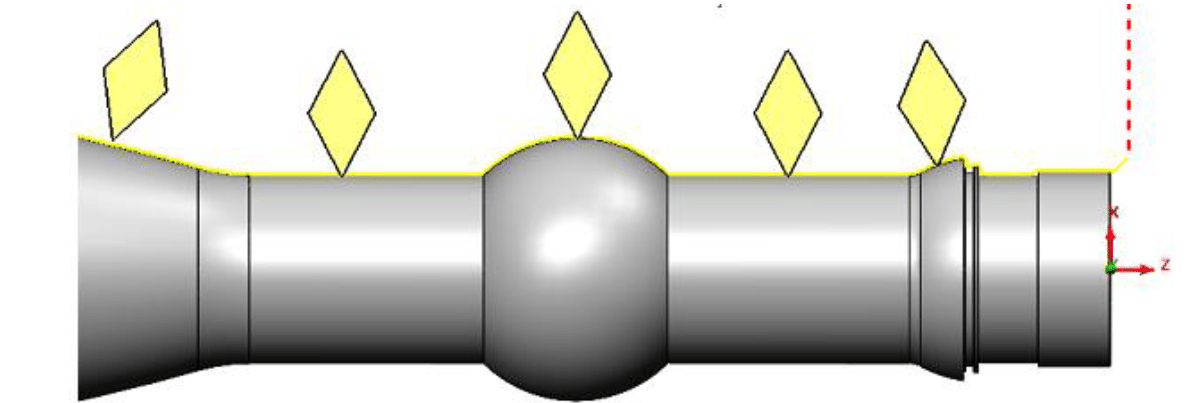

At an Angle to the Feature Curve

When this option is selected, the tool will always maintain the same Effective Lead Angle or Normal Angle while machining each segment of the feature. This will result in a higher number of tool rotations. This Effective Lead Angle/ Normal Angle can be defined/edited in the Angles group box within this dialog box.

You can control the transition of the Turn Insert at sharp corners using the parameters within the Sharp Corners group box of this dialog box.

- Rotate at Direction Change – When this option is selected, the direction change will happen when the Turn Insert is at the vertex (edge of the feature segment).

- Smooth – When this option is selected, the Turn Insert will gradually traverse over the sharp corner. The tool will not maintain the defined Normal angle or Effective Lead Angle with this setting. (The tool will not be exactly normal to the Turn feature segment)

Here is a quick Video on B axis continuous turning from NILES-SIMMONS

For more information on CAMWorks Software and product enquiries visit us at https://nctools.com.au/ or call us on +61 3 8618 6884