Probing has become an established best practice for maximizing the efficiency, quality, capability, and accuracy of machine tools. Standard routines built into modern CNC controls simplify the integration of probing cycles into machining operations. Machine tool probing potentially makes sense at nearly every stage of the machining process:

Setup

This Locates the part automatically and establishes a work coordinate system. Probing cuts setup time, increases the spindle availability and Reduces the fixture costs. On complex parts, 45 minutes of fixture alignment can be replaced by 45 seconds of probing, this can be automatically done by the CNC itself.

Fail-safe operation

After the completion of the probing cycle, the CNC will automatically determine the data such as work coordinate updates, tool geometry changes, part measurement, etc. This eliminates costly errors that are made due to miscalculations of information.

Part identification

Probing can determine that the correct part has been loaded during automated part processing. This part Identification procedure lets the CNC use the correct program.

Tool-setting

A Tool-setting probe is the best solution for on-machine verification of tool geometry and condition. In addition to the spindle-mounted probe, another type is the table-mounted tool-setting probe. The Tool-setting probe can automatically set length, diameter and identify broken tools.

In-process control – This uses the spindle-mounted probe to monitor the size and position of machined features during the cutting process. A probe can be programmed to monitor the process and automatically adjust work coordinates. This helps to eliminate scrap, reprogramming, or potential rework.

Inspection – Probing eliminates the delays of manual inspection, especially when the operator needs to get the part out of the setup to inspect the part, then reinstall it for any corrections.

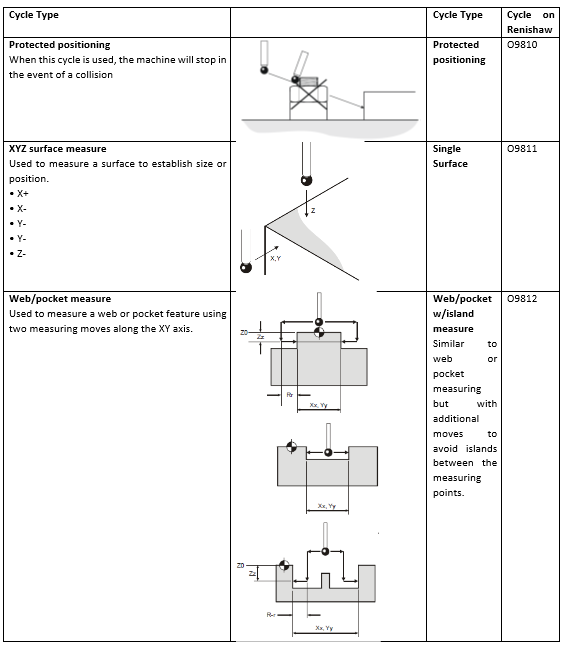

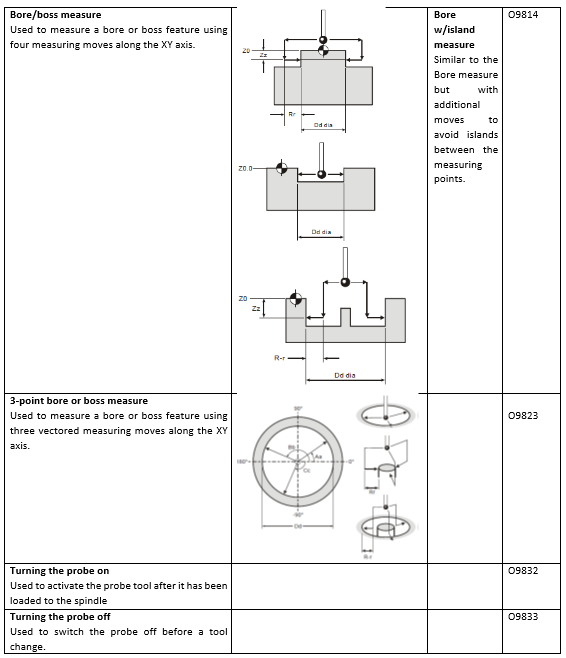

Supported Cycle Types

Though CAMWorks is user-friendly and self-explanatory, we are here to help should you require assistance.

For more information on CAMWorks software and product enquiries, visit us at http://www.nctools.com.au/or call us at +61 3 8618 6884.