Shorten the Process using MaxxCAM 2D CAD

MaxxCAM’s parametric 2D CAD functionality is a powerful feature that empowers users to create and modify designs with ease and precision. This innovative tool within the MaxxCAM software suite streamlines the design process, allowing users to quickly generate accurate and customizable 2D CAD models.

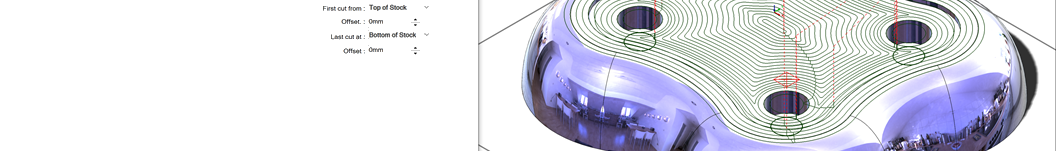

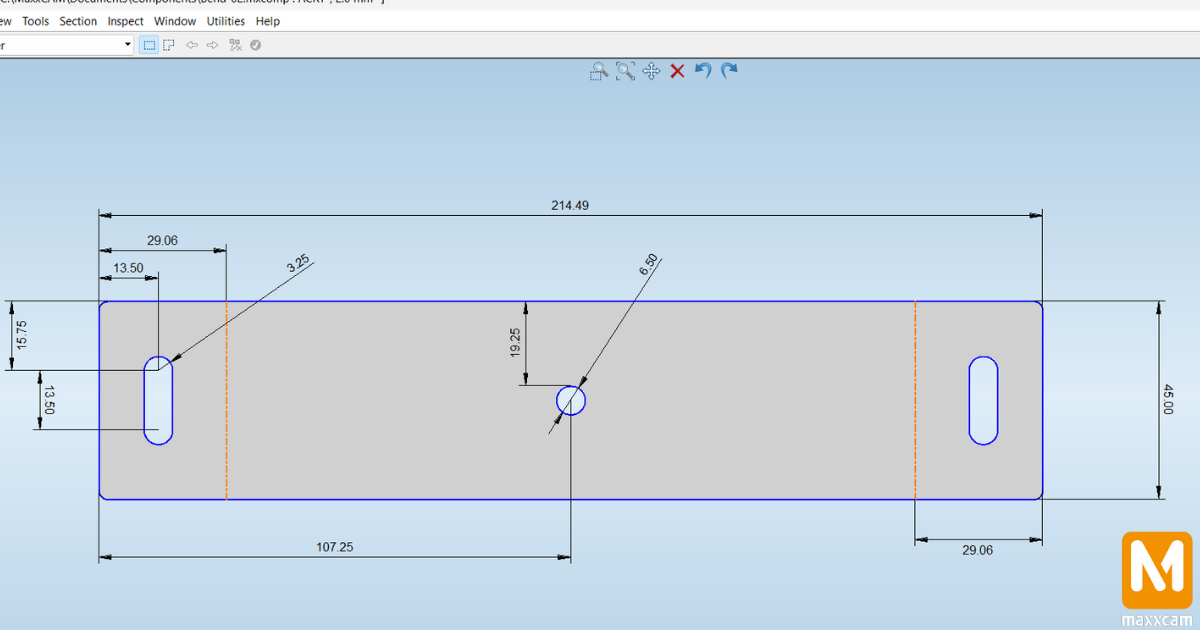

Parametric design is a methodology that uses parameters and relationships between elements to define and modify a design. With MaxxCAM’s parametric 2D CAD, users can define various parameters such as dimensions, angles, and constraints that govern the behavior and characteristics of the design. These parameters can be easily adjusted, and the design updates automatically to reflect the changes, saving valuable time and effort.

One of the key advantages of MaxxCAM’s parametric 2D CAD is its flexibility. Users can create designs from scratch or import existing drawings and easily modify them using the parametric features. This allows for quick iteration and experimentation, enabling designers to explore different design possibilities and make adjustments as needed. Whether it’s adjusting the size, position, or shape of elements, MaxxCAM’s parametric 2D CAD provides the tools to fine-tune designs to exact specifications.

Furthermore, MaxxCAM’s parametric 2D CAD supports a wide range of geometric entities and drawing tools. Users can create lines, arcs, circles, polygons, and other shapes effortlessly. Additionally, the software offers advanced features like constraints and relationships, allowing users to define dependencies between elements and maintain design integrity. Constraints ensure that designs adhere to specific rules, such as maintaining parallelism, perpendicularity, or concentricity.

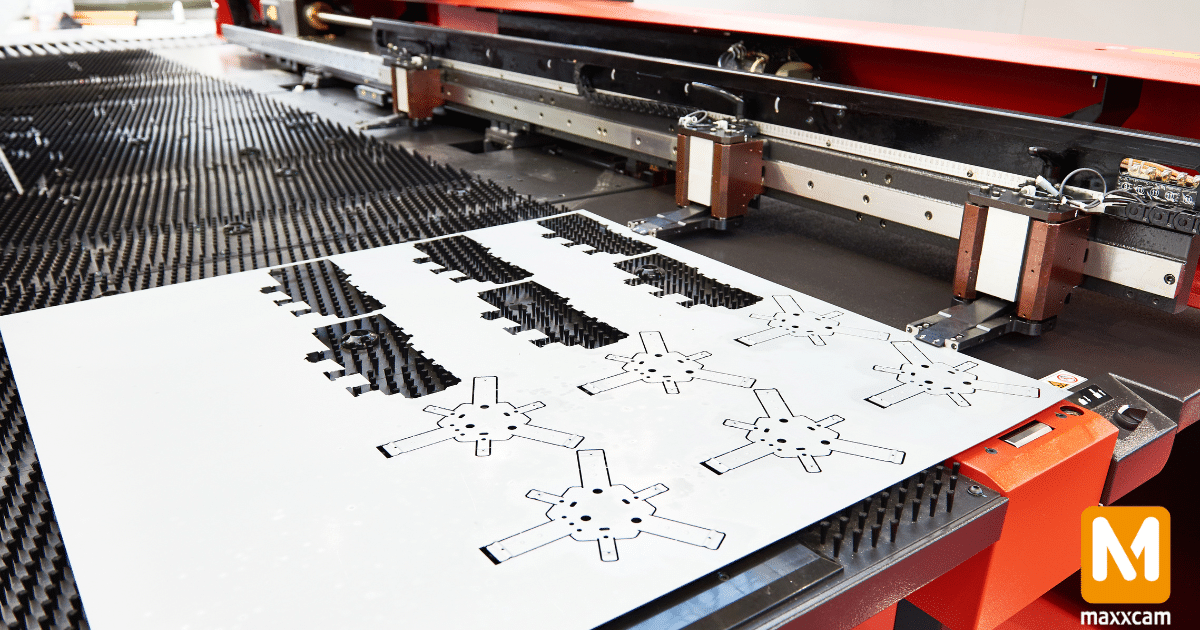

Another notable feature of MaxxCAM’s parametric 2D CAD is its compatibility with other modules within the software suite. Users can seamlessly integrate their 2D CAD designs with the CAM functionalities, enabling a smooth transition from design to production. This tight integration streamlines the workflow, eliminating the need for data conversions or manual re-entry of design specifications.

MaxxCAM’s parametric 2D CAD is a valuable tool for designers and engineers in various industries. Its flexible and intuitive interface, coupled with the ability to create and modify designs using parameters and constraints, enables efficient and precise design iterations. With the seamless integration with other modules within the MaxxCAM software suite, users can seamlessly transition from design to manufacturing, optimizing productivity and accuracy.

For more information about MaxxCAM Software and product inquiries, please contact us at https://nctools.com.au/service/maxxcam-software/ or call us on +61 3 8618 6884