MaxxCAM – Quick Nesting with Maximum Material Utilisation

MaxxCAM – Optimize Material Utilization with Quick Nesting MaxxCAM nesting software features a powerful nesting engine equipped with dedicated algorithms for Punch, Profile, Punch/Shear, and more. These algorithms ensure maximum material utilization based on your specific requirements. Nesting with MaxxCAM: Start

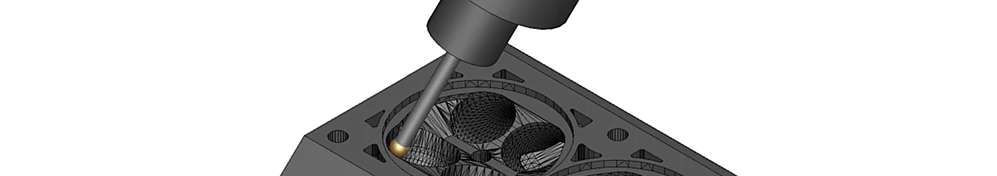

Use CAMWorks 5 Axis Trimming for Clean edges

5 Axis Mill can be used to trim material from parts that have been thermoformed or are composed of composite material. The majority of plastic thermoformers and composite part makers use 5-axis CNC trimming equipment as this is regarded as the

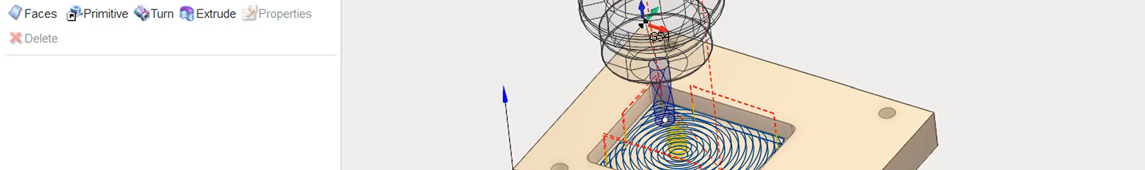

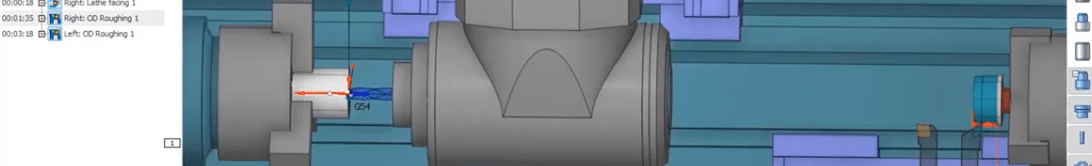

Do multiple tasks simultaneously with SprutCAM

Machines that perform multiple tasks simultaneously are known as multitasking machines (MTM). MTM can vary greatly. As an example, a multi-task turn-milling centre typically has several spindles or/and turret heads inside one housing. In some cases, a multi-task machine consists

Onshape Connector – SprutCAM plugin

Onshape is designed from the ground up to be a modern offering tailored for today's professional design teams. With SprutCAM Onshape Connector, you'll experience a smooth transition from CAD to arguably one of the best system today for machine tool

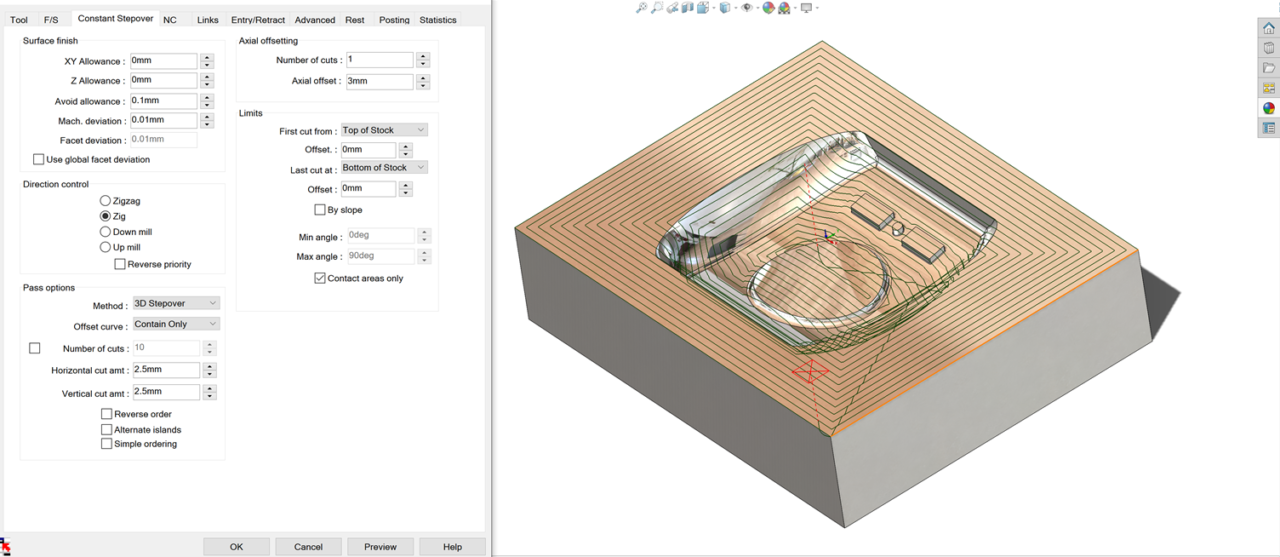

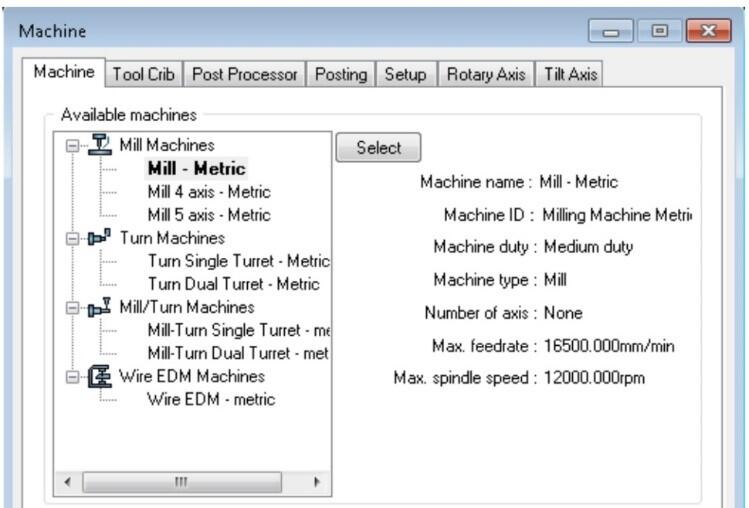

Utilise CAMWorks to machine your complex parts

With CAMWorks, complex parts can be programmed with greater accuracy. In this blog, we will examine some of the methods that can be used to program an impeller blade with complex geometry. Create a new multisurface feature and select the face

What’s New in SprutCAM 15

As times change, so do the tools you need. A number of enhancements and additions have been made to SprutCAM 15 to enhance your programming experience. Here is a list of them. Multi-parts projects/Tombstone machining The possibility of machining several

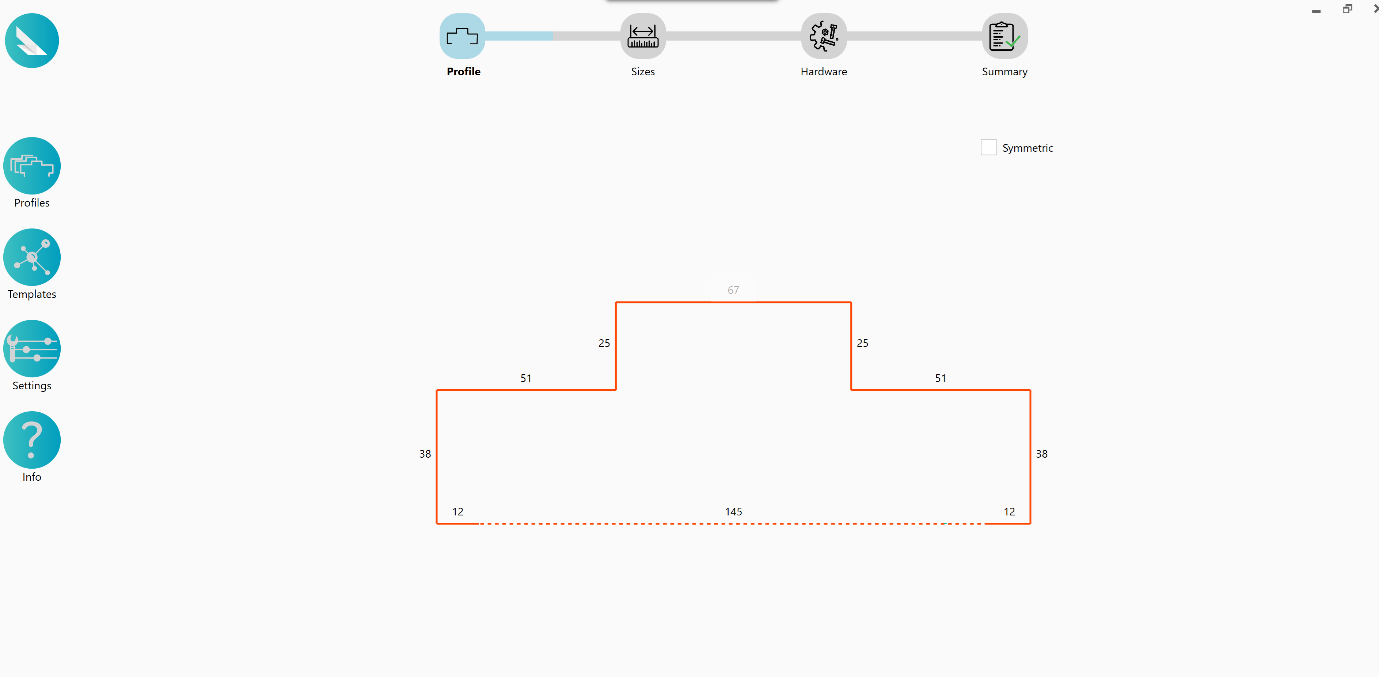

5 Reasons why Smart Cut Quote Software can speed up your laser Quoting process

The laser cutting quoting software saves you time In the laser cutting business, determining the price of your cutting Service can be one of the most challenging tasks. Developing a price for your product/service depends on so many variables that it

Multi Axis operations with CAMWorks – Port Machining

Port Machining is a common strategy with 5 axis machining to machine the inside of an intake or exhaust channels and other ports. In this blog, we will see the procedure to set this up. This can be done quickly

SprutCAM 5 axis machining and how it can benefit your business

5-axis refers to a machine's ability to move a tool in five directions at once. The main benefit of 5-axis machining is that it is able to produce complex shapes using a single setup. SprutCAM generates toolpaths for 5-axis milling

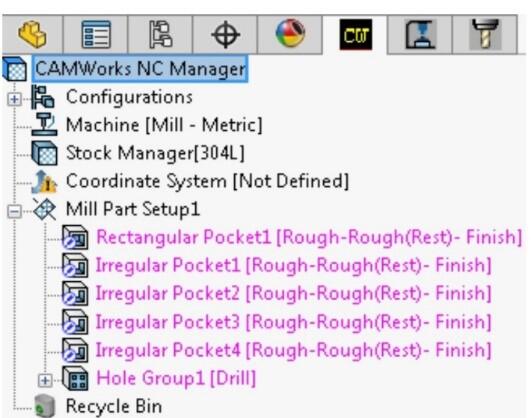

Automate your manufacturing process with Feature-based machining (FBM)

Automate your manufacturing process A key function of manufacturing process planning is the planning of machining sequences. The term Manufacturing Feature refers to a component of a part that can be manufactured using a standard machining process. Holes, pockets, slots, grooves,