With CAMWorks, complex parts can be programmed with greater accuracy. In this blog, we will examine some of the methods that can be used to program an impeller blade with complex geometry.

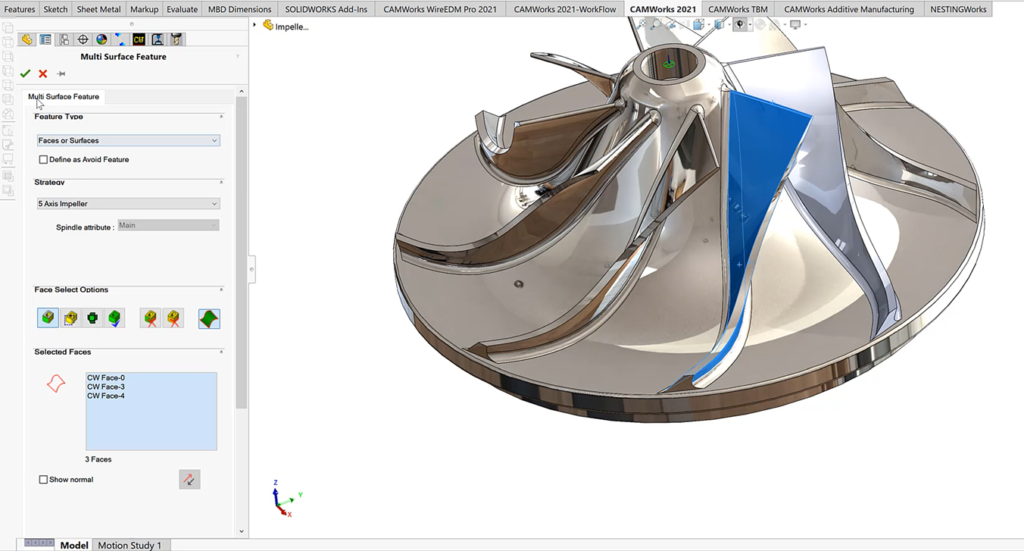

Create a new multisurface feature and select the face type and strategy as Faces or surfaces, and 5 Axis Impeller. Then select the required faces and click OK.

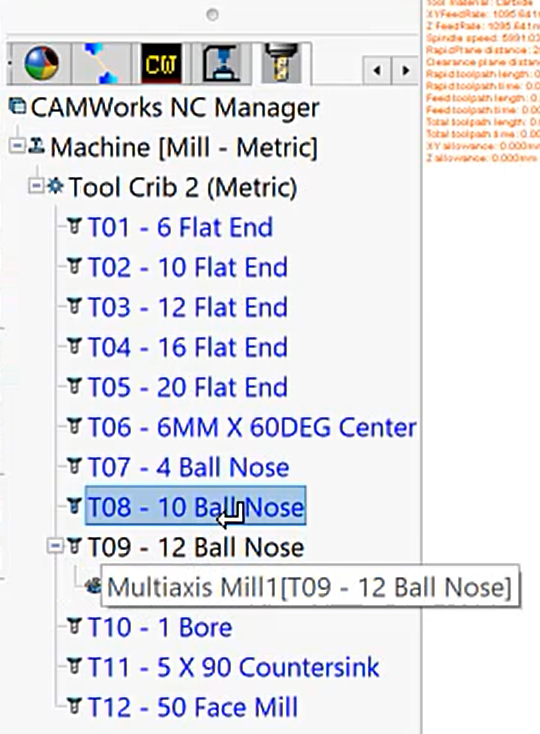

Generate the operational plan and swap out the tools as necessary.

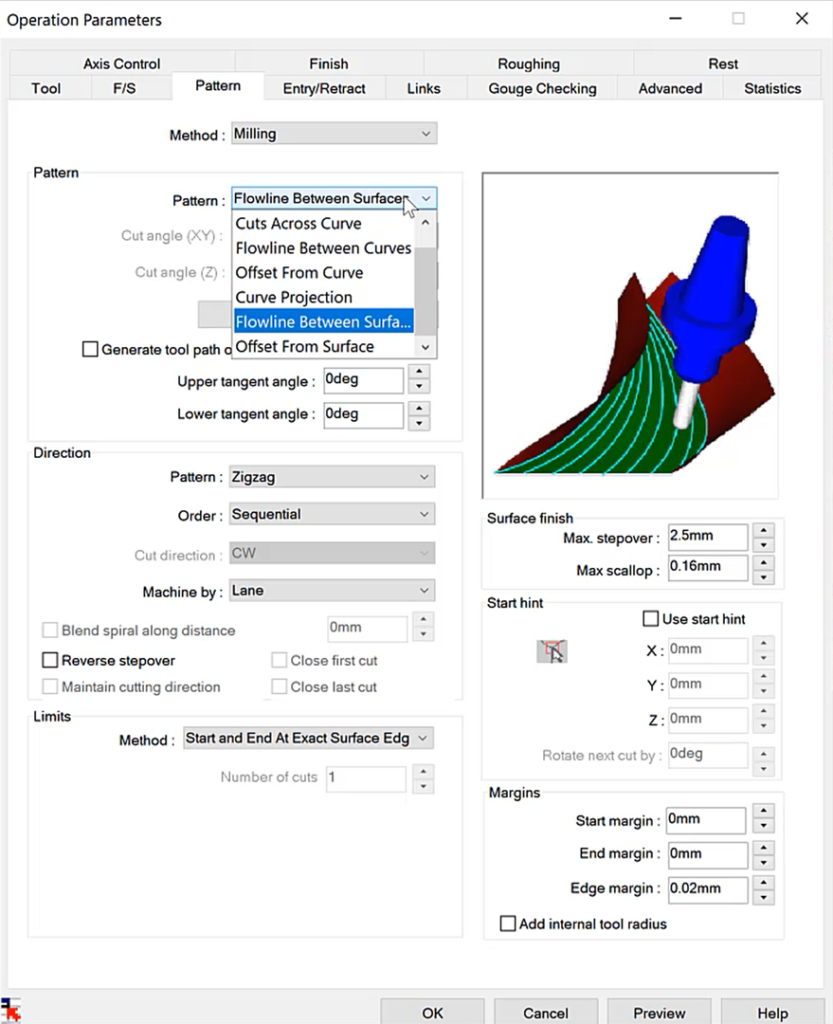

In the next step, edit the operational parameters in accordance with the desired outcome.

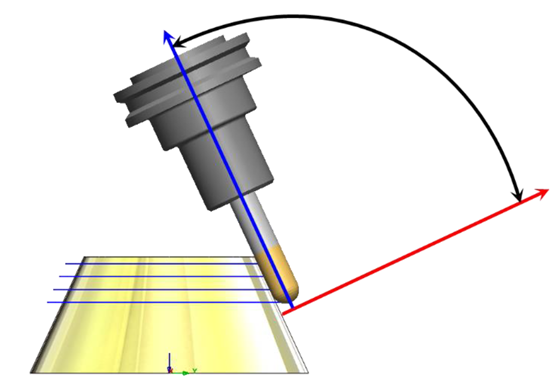

It is important that the tool be tilted so that it is close to perpendicular to the blade surface. To accomplish this, we will modify the axis control parameters.

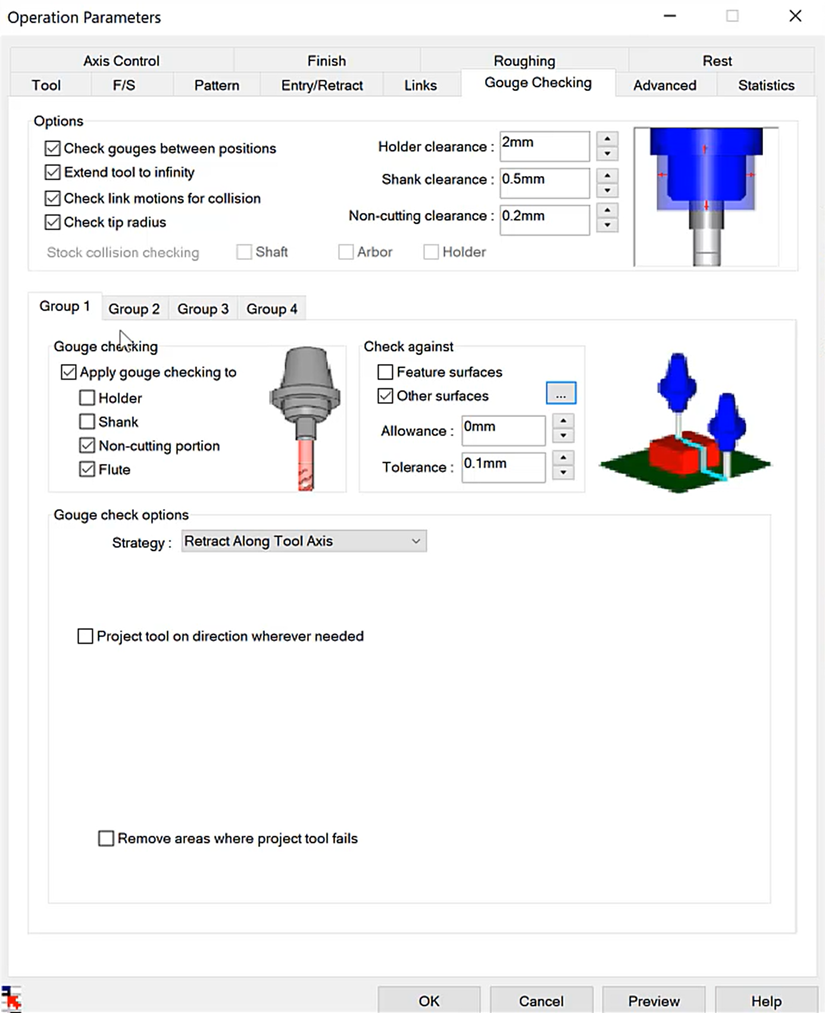

It is likely that the toolpath will gouge the impeller’s floor and the blade’s blade if it is generated. A gouge check strategy can be defined in which the tool is pushed back on its axis when it gouges the floor and tilted when it gouges the blades. Therefore, adjust the gouge parameters in accordance with the toolpath.

Due to the nature of multi-axis operations, it may be necessary to revisit the operation parameters in order to get a better result.

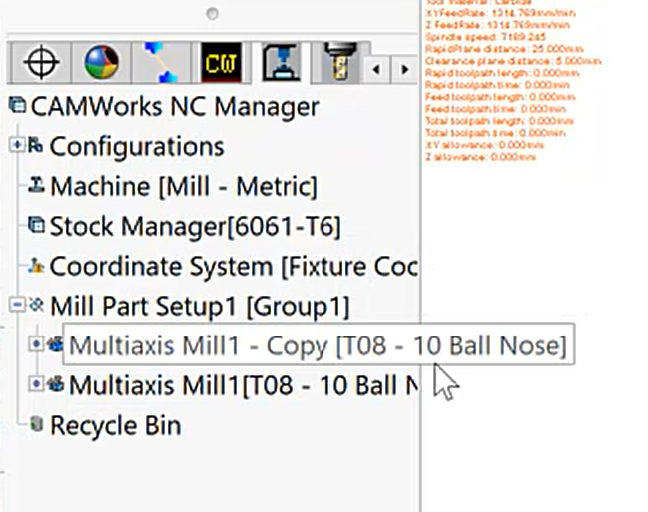

A good practice is to copy an operation and then make changes to the copy so that we can examine whether we can obtain a better toolpath without affecting the original operation.

Using this example, we will change the pattern type to see if we can reduce the excessive rapid movements in the toolpath.

Although CAMWorks is intuitive and straightforward to use, if assistance is required, it can be provided.

For more information on CAMWorks Software and product enquiries, visit us at http://www.nctools.com.au/or call us on +61 3 8618 6884.