Multi Axis operations with CAMWorks – Port Machining

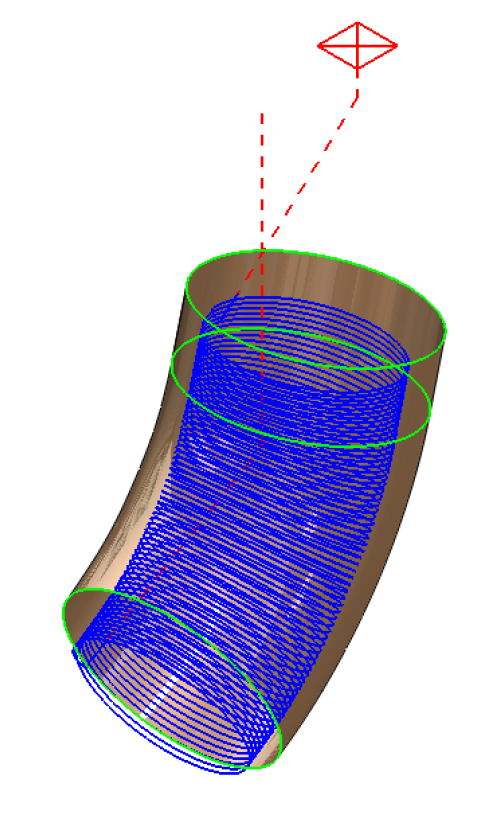

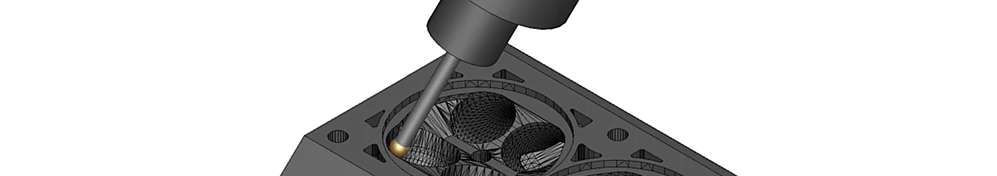

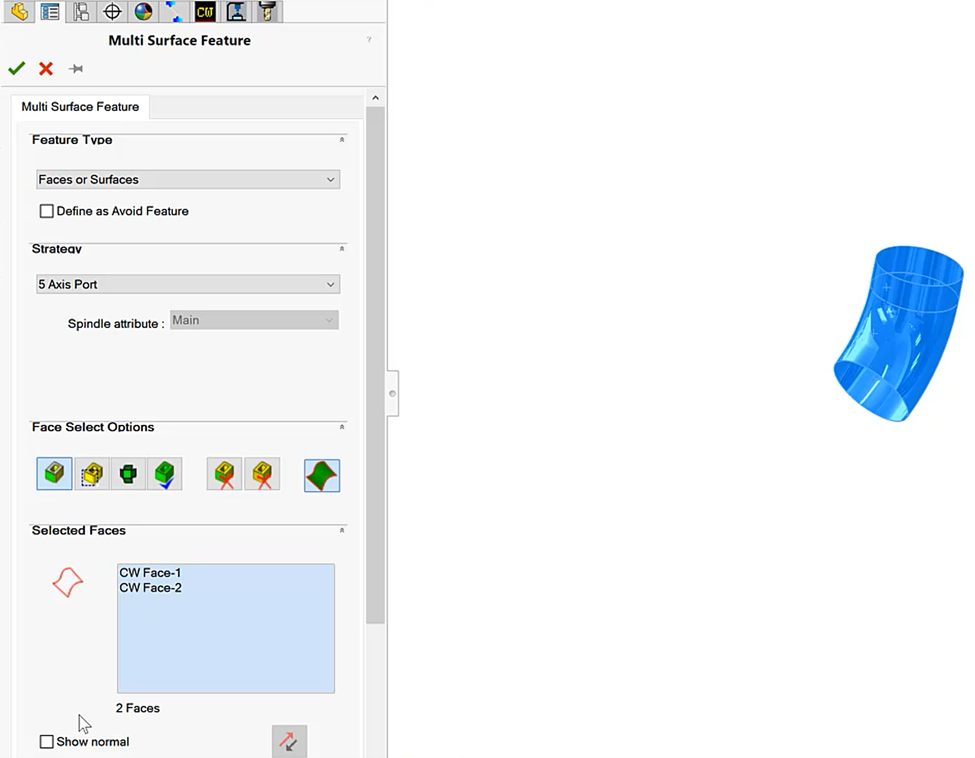

Port Machining is a common strategy with 5 axis machining to machine the inside of an intake or exhaust channels and other ports. In this blog, we will see the procedure to set this up. This can be done quickly with greater accuracy. The first step is to display the port Surface in the Surface bodies folder in SOLIDWORKS and hide the solid body of the part. A surface body has already been modelled for this part. We will be using this surface to create the finishing toolpath.

Although CAMWorks is intuitive and straightforward to use, if assistance is required, it can be provided. For more information on CAMWorks Software and product enquiries, visit us at http://www.nctools.com.au/or call us on +61 3 8618 6884.