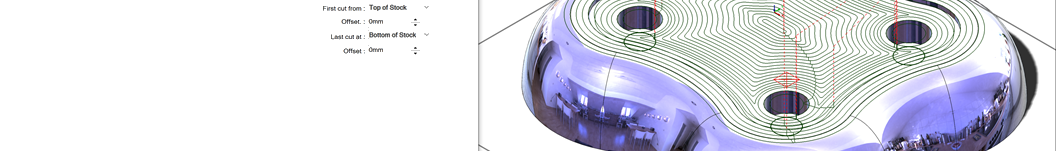

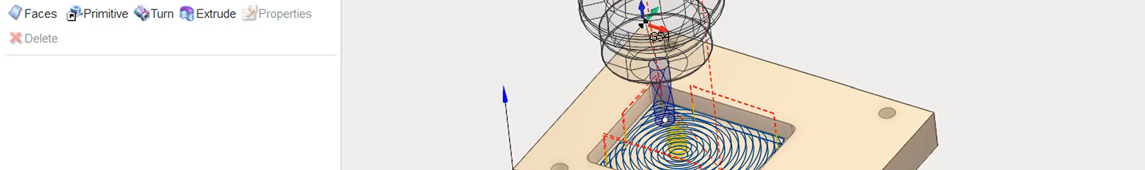

SprutCAM G-code Based Simulation

SprutCAM G-code based simulation allows the consideration of features of the implementation of the postprocessor in the simulation processing. In this mode, the system automatically checks NC code for each operation while calculating machine Kinematics and limits. G-code based simulation function

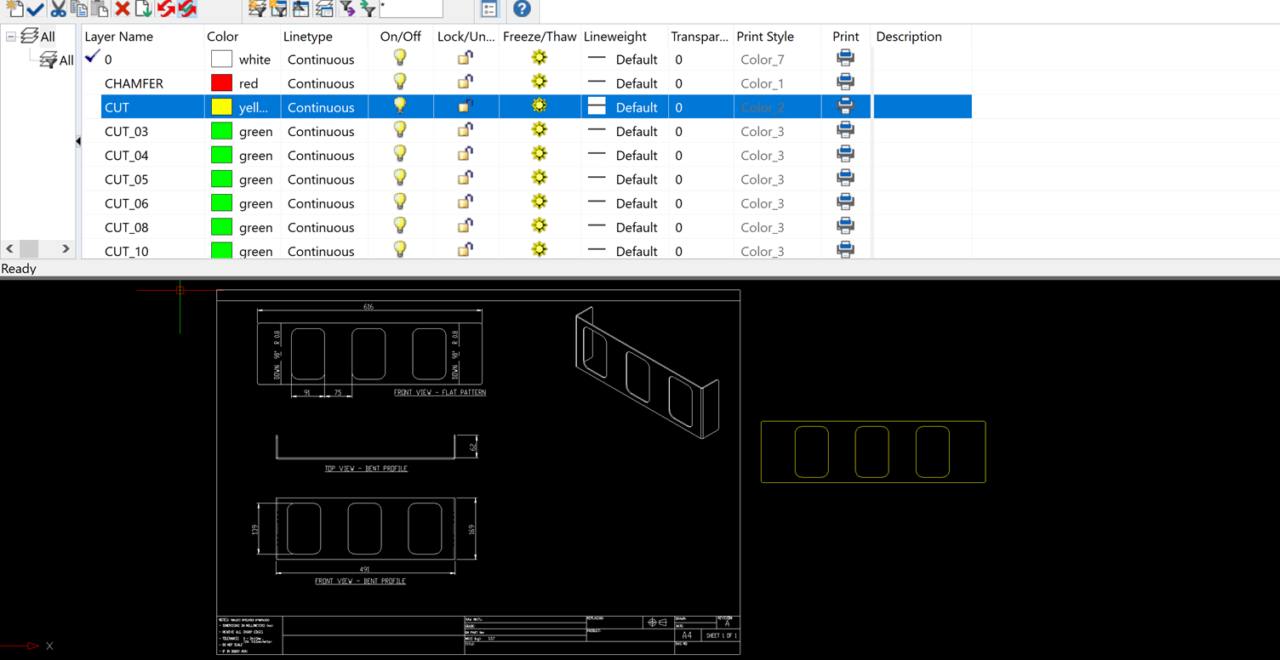

SprutCAM knife cutting Module

SprutCAM Knife cutting tools are used for cutting of flexible and semi-rigid materials. The CNC machines are equipped with a variety of knife tools and blades. The blade of this cutting tool moves on the surface of the material as per

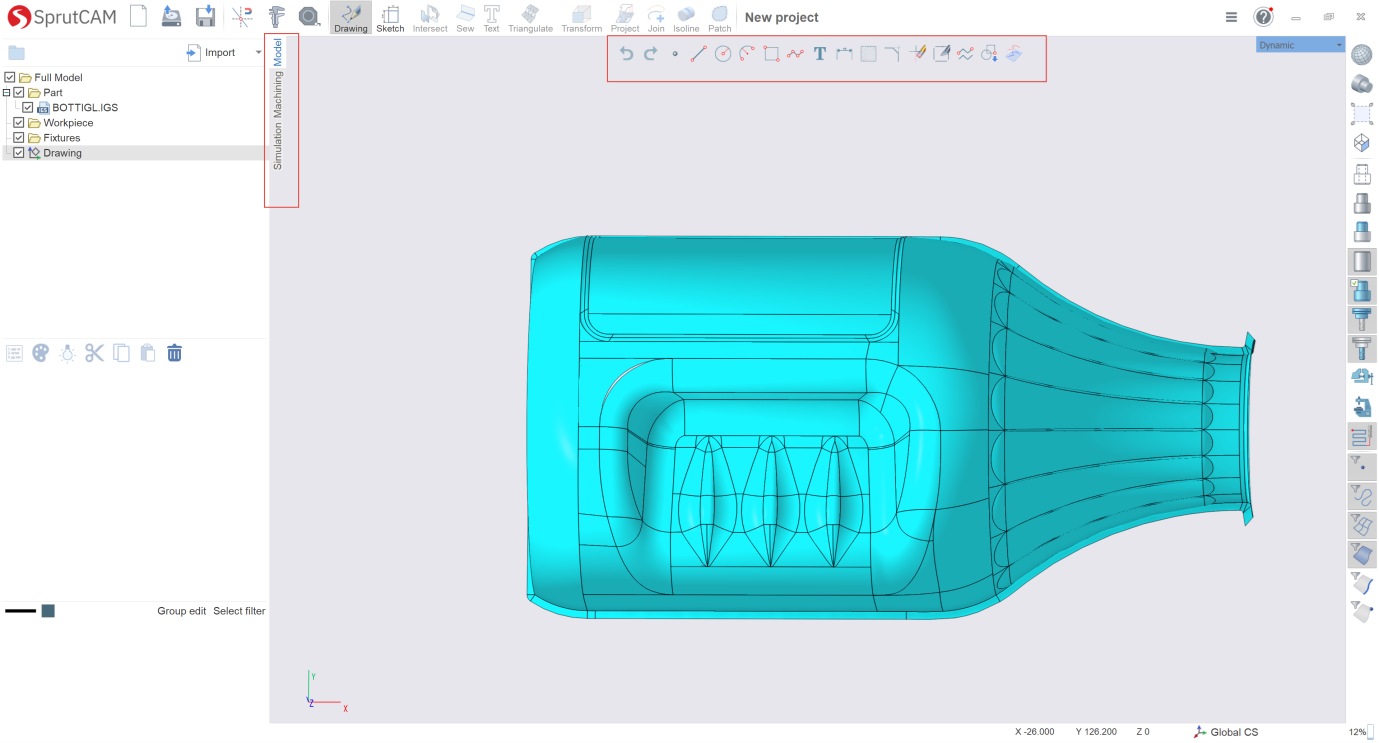

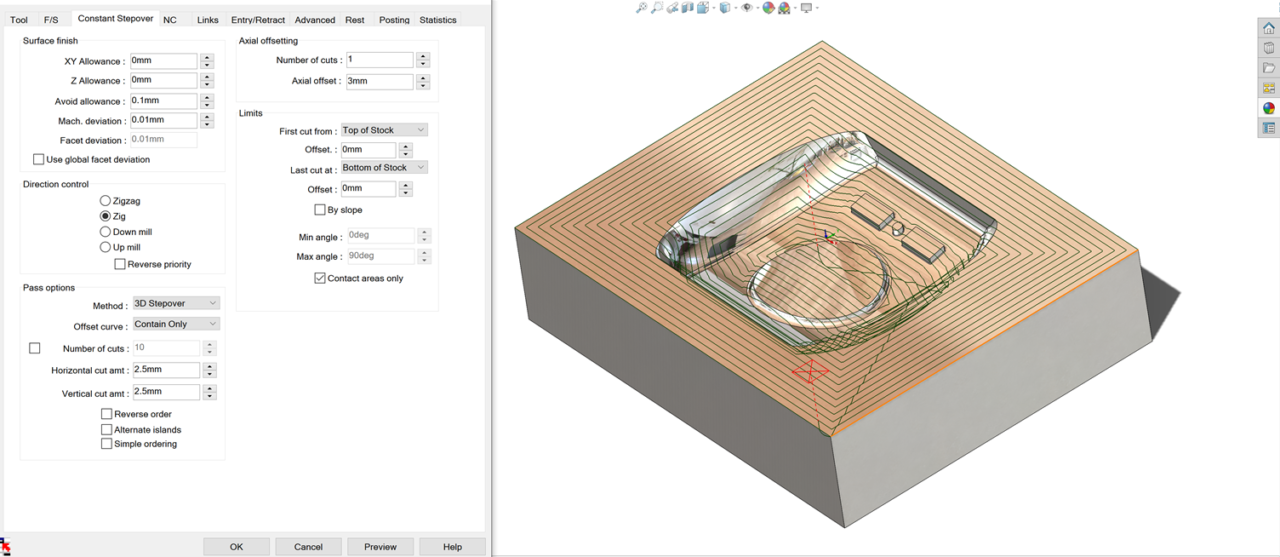

SprutCAM – Cost-effective and powerful solution for CNC programming

SprutCAM is a new-generation software program that works directly with the imported CAD data; it automatically calculates and generates an efficient toolpath for machining a model that can be graphically simulated to allow the user to check the machining parameters.

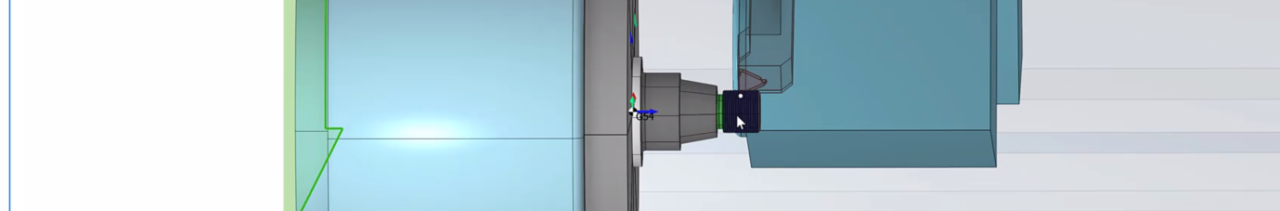

CNC shop – ready to embrace a Digital Twin?

CNC shop - A digital twin is a digital version of your CNC machine inside your CAM Software. A digital twin is not just limited to your tool simulation. An accurate kinematic model of your CNC machine, including travel limits,

Program your Industrial Robots using SprutCAM

Programming of industrial robots is a quick and straightforward process in SprutCAM. SprutCAM can be used for cutting, milling, painting, welding, and other applications. The programming process of an industrial robot is the same as the conventional milling machines except

SprutCAM Lathe Exercise-Multiple Setups for Turning

SprutCAM is a great solution for quick programming and cost-effective machining. It brings you some better features and options among all CAM software. Using SprutCAM, we can program a double-ended lathe part machining with a single chuck. This can be done in

SprutCAM helps you save unnecessary programming time

Today’s industries are looking for the quickest and optimal CNC programming application to improve productivity. SprutCAM is arguably the ideal solution for that purpose. Even though the SprutCAM has a lot of time-saving features, we can still make use of

Do multiple tasks simultaneously with SprutCAM

Machines that perform multiple tasks simultaneously are known as multitasking machines (MTM). MTM can vary greatly. As an example, a multi-task turn-milling centre typically has several spindles or/and turret heads inside one housing. In some cases, a multi-task machine consists

Onshape Connector – SprutCAM plugin

Onshape is designed from the ground up to be a modern offering tailored for today's professional design teams. With SprutCAM Onshape Connector, you'll experience a smooth transition from CAD to arguably one of the best system today for machine tool

Utilise CAMWorks to machine your complex parts

With CAMWorks, complex parts can be programmed with greater accuracy. In this blog, we will examine some of the methods that can be used to program an impeller blade with complex geometry. Create a new multisurface feature and select the face