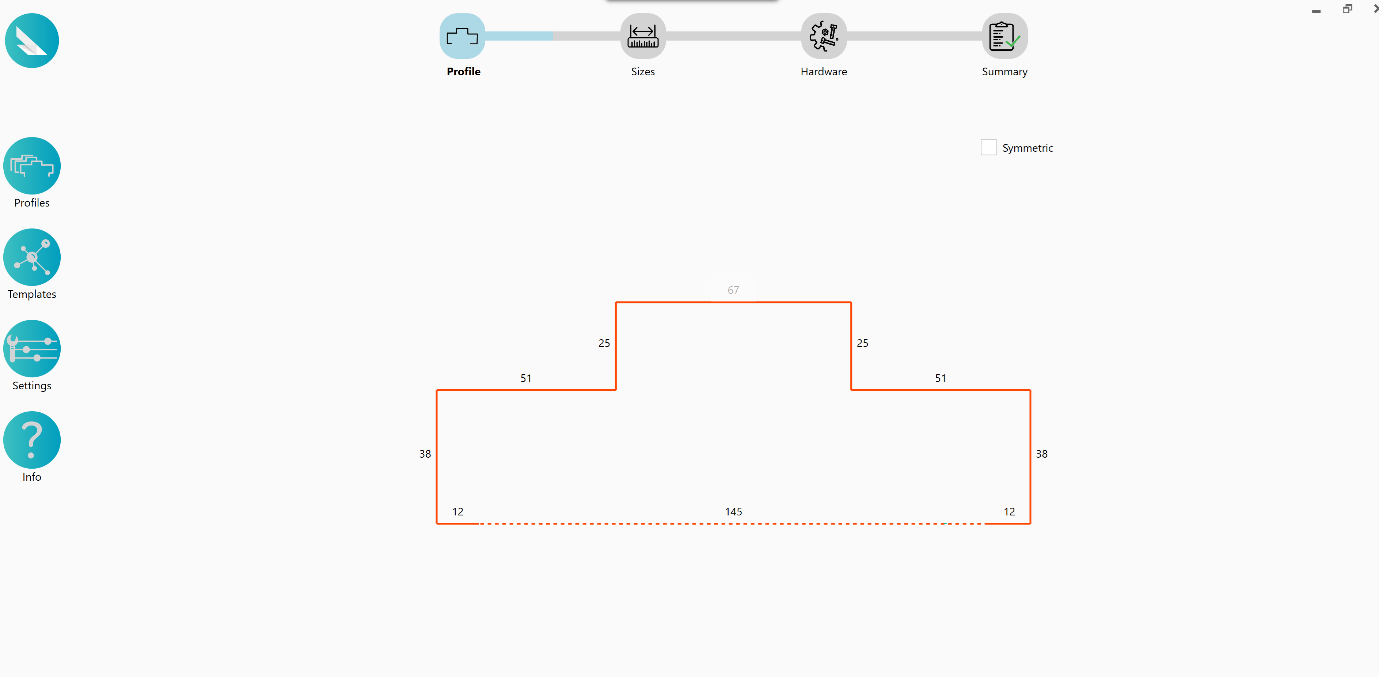

MaxxCAM – Quick Nesting with Maximum Material Utilisation

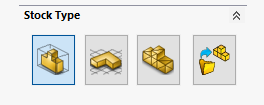

MaxxCAM – Optimize Material Utilization with Quick Nesting MaxxCAM nesting software features a powerful nesting engine equipped with dedicated algorithms for Punch, Profile, Punch/Shear, and more. These algorithms ensure maximum material utilization based on your specific requirements. Nesting with MaxxCAM: Start

Onshape Connector – SprutCAM plugin

Onshape is designed from the ground up to be a modern offering tailored for today's professional design teams. With SprutCAM Onshape Connector, you'll experience a smooth transition from CAD to arguably one of the best system today for machine tool

Do multiple tasks simultaneously with SprutCAM

Machines that perform multiple tasks simultaneously are known as multitasking machines (MTM). MTM can vary greatly. As an example, a multi-task turn-milling centre typically has several spindles or/and turret heads inside one housing. In some cases, a multi-task machine consists

Why Manufacturing companies need 5 axis Machines

Programming with SprutCAM’ S 5 axis: Currently, a significant number of manufacturers are interested in Multiaxis machining. Generally, this is because it will be a single solution for all types of machining. There are a wide range of advantages associated with

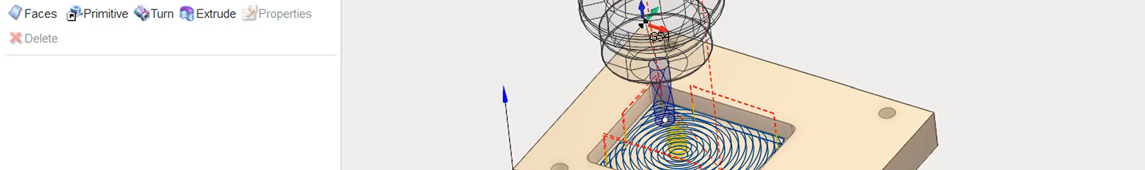

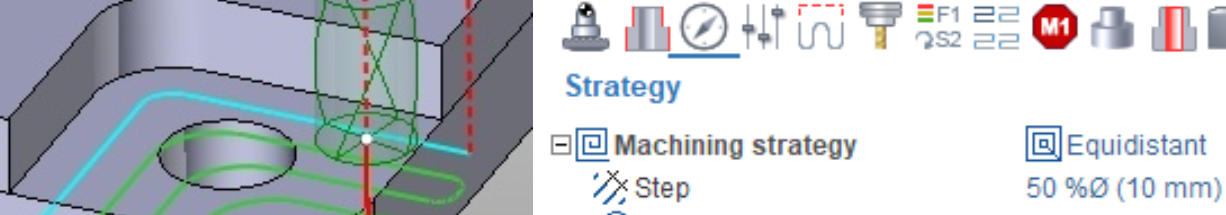

High-performance cutting with SprutCAM

Sprut HPC is a high performance cutting strategy designed for efficient removal of material from both open and closed pockets. The following operations support this strategy. Rough waterline Pocketing Pocketing 2.5D Flat land finishing You can select this strategy from the option

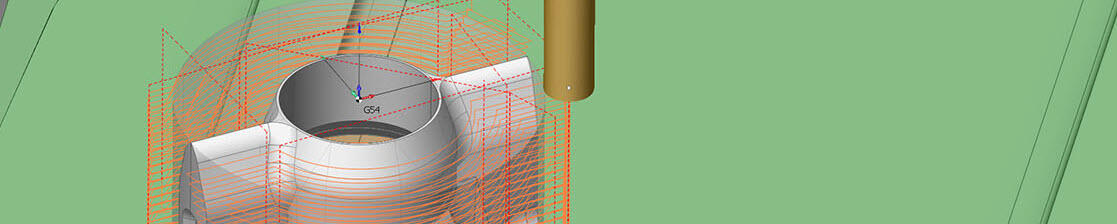

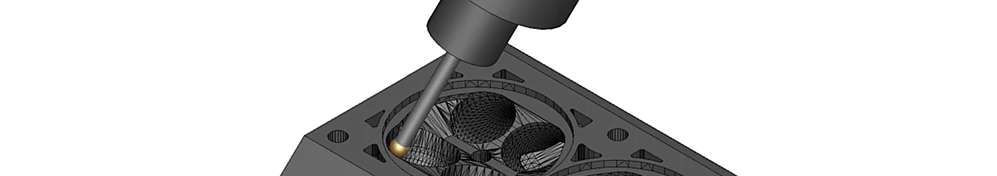

Multi Axis operations with CAMWorks – Port Machining

Port Machining is a common strategy with 5 axis machining to machine the inside of an intake or exhaust channels and other ports. In this blog, we will see the procedure to set this up. This can be done quickly

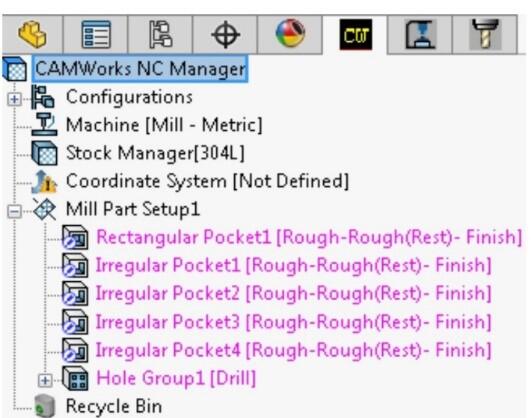

Automate your manufacturing process with Feature-based machining (FBM)

Automate your manufacturing process A key function of manufacturing process planning is the planning of machining sequences. The term Manufacturing Feature refers to a component of a part that can be manufactured using a standard machining process. Holes, pockets, slots, grooves,

Introducing CAMWorks 2022

CAMWorks 2022 delivers the performance improvements you need so you can get your work done faster! CAMWorks constantly updates its software to satisfy the requirements of the manufacturing industry, as well as offering features to assist manufacturers through its software. A

SprutCAM EDM Machining

With SprutCAM's wire EDM machining, SprutCAM EDM can produce curvilinear contours in 2 and 4 dimensions. EDM is an electrical discharge machining process that is primarily used for machining applications involving this process. In this device, a current is transmitted between

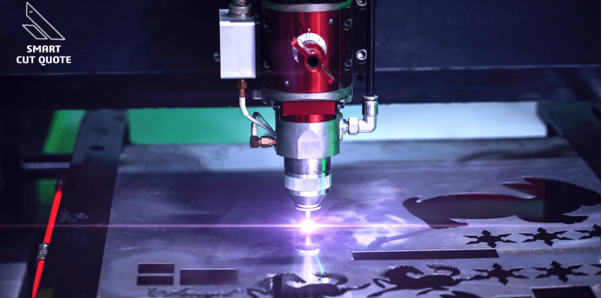

5 Reasons why Smart Cut Quote Software can speed up your laser Quoting process

The laser cutting quoting software saves you time In the laser cutting business, determining the price of your cutting Service can be one of the most challenging tasks. Developing a price for your product/service depends on so many variables that it