Introducing CAMWorks 2022

CAMWorks 2022 delivers the performance improvements you need so you can get your work done faster!

CAMWorks constantly updates its software to satisfy the requirements of the manufacturing industry, as well as offering features to assist manufacturers through its software. A new version of CAMWorks may include the following features and enhancements:

- Support for barrel tools in milling operations:

The barrel tool has been added to CAMWorks2022. A parametric shape can be defined for the barrel tool. The tool is frequently used for finishing operations, as it can produce a smoother surface finish. CAMWorks supports five types of barrel tools: standard, conical tangent, tapered, lens, and advanced. Further, barrel tools support multi-axis milling operations, three-axis milling operations, and two-axis milling operations (not supported for centre drills, counter sinks, tapping, thread milling, or VoluMill operations).Tech database allows you to access and modify barrel tools by selecting mill tooling, cutters, and then barrel tools. Next, you can define tool parameters in specific dialogue boxes and save your changes.

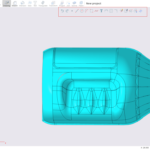

- Improved user interface for defining and editing multisurface features:

CAMWorks2022 has updated its user interface to make it easier to define and manipulate the machining of multi-surface features. Geometry tab created under operation parameters allows users to view, add, and modify multisurface features. As well, the automatic contain area feature has been moved to the geometry tab.

- Machine to mean for tolerance-based machining:

Using the machine-to-mean function, all dimensions are machined in mean condition and is available on the Run tab in the tolerance-based machining dialog box. This is applicable to milling operations. The part geometry must contain multiple dimensions and several tolerance ranges in order to support this feature.

- Conversion of rapid moves to high feed moves for VoluMill toolpaths:

CAMWorks2022 has introduced check boxes for converting rapid moves into high feed moves in roughing and area clearance operations. A click of the check box initiates the conversion. The feedrate changes automatically. The check box is located in the F/S tab under operation parameters.

- Conversion of Arc moves to line moves for VoluMill toolpath:

CAMWorks2022 has introduced an option for VoluMill which converts Arc moves into number of lines moves. VoluMill provides this feature under its settings. To use it, you must check the checkbox. It is unchecked by default. This will only change the arc move to a line move.

- Enhanced toolpath for Contour mill operation:

CAMWorks2022 has updated the toolpath motion for contour milling. CAMWorks makes sure that the modification maintains the user-defined values for the entry and exit of the tool. The automatic adjustment is determined by the diameter of the tool.

CAMWorks2022 offers a wide range of additional features and enhancements in addition to these

Contact us for the upgrade +61 3 8618 6884