High-performance cutting with SprutCAM

Sprut HPC is a high performance cutting strategy designed for efficient removal of material from both open and closed pockets.

The following operations support this strategy.

- Rough waterline

- Pocketing

- Pocketing 2.5D

- Flat land finishing

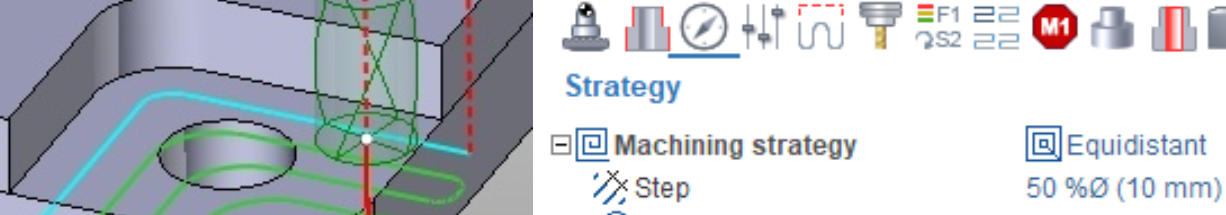

You can select this strategy from the option area in the machining strategy drop-down menu. Once the HPC strategy has been selected, the remaining options will be displayed.

Trochoidal Arc:

It is suitable for rough milling of confined cavities, pockets, and grooves, particularly when there is a vibration problem.

Trochoid milling is defined as circular milling with simultaneous forward motions. Due to the controlled arc of engagement, low cutting forces are generated, enabling high axial depths of cut. In the new trochoidal arcs, tool overload is avoided without reducing feedrate. This results in significantly smoother machining.

Here are a few important features of HPC strategy to prove more efficient and compatible.

Back-off distance parameter:

As a result of this option, the tool can be lifted above the existing machined surface when it moves to the next trochoidal arc start position.

Rounded links in zig-zag mode:

Rounding of the links is performed using the finish rounding radius, rough rounding radius, and linking radius values

Links on the same Z-level:

In climb and conventional milling types, the tool goes directly to the next path without retracting to a safe level. When a rapid motion is performed over a surface that has already been machined, the tool follows the command of tool back off distance and at the same time idle radius is also utilized to ensure the motion is smooth and damage-free.

Safe Distance:

The safe distance is used to move tools down and up and from and to the safe surface. The vertical motion is determined by the distance from the workpiece. It is no longer necessary to enable the approaches/retractions to exclude rapid feed collisions in version 10. For SprutCAM to be able to see predrilled holes when roughing, the pre-drill tool diameter must be greater than the mill tool diameter by at least double the safe distance.

Rapid feed links

In most cases, link moves are calculated using either the next feed or the return feed values. By default, the return feed is set at 300% of the work feed, which is a non-cutting feed. During simulation, if cutting is detected in the return feed move, this move will be classified as an error. If the link length is less than the short link distance, then either the next feed or return feed values will be used.