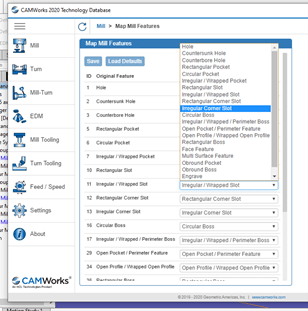

Make your User-defined CAMWorks Database

The intelligence behind CAMWorks machining automation is the Technology Database (TechDB). The Technology Database is shipped with data that is considered generally applicable to most machining environments. To gain full advantage of CAMWorks, you will want to modify this data

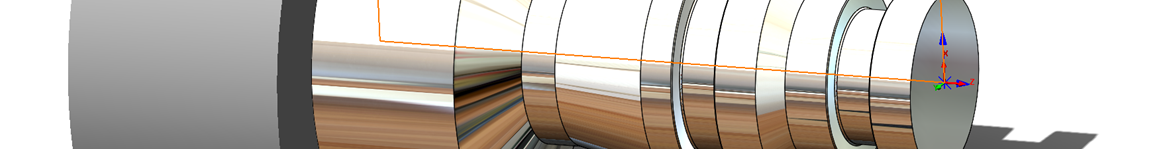

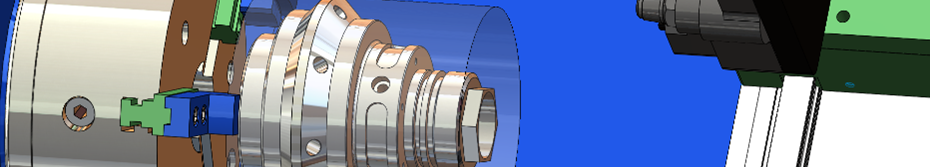

Automatic Feature Recognition For Turning-CAMWorks

Programming for a lathe turning becomes easy and quick when you have CAMWorks. CAMWorks 2 and 4 Axis Turning includes automatic roughing, finishing, grooving, threading, cutoff, and single point (drilling, boring, reaming, and tapping) cycles. CAMWorks turning can be preferred when you need a

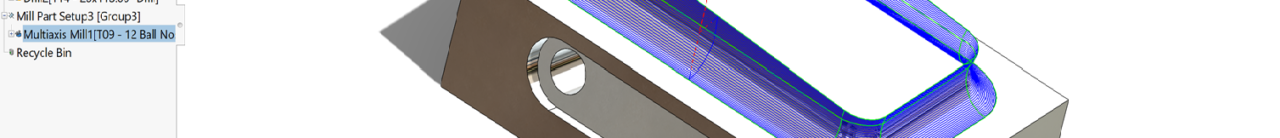

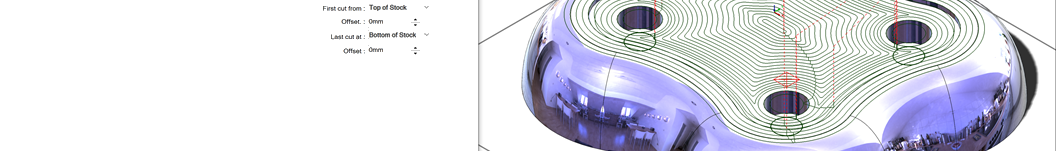

CAMWorks 5-Axis Module for greater machining productivity

When someone uses the term 5-axis machining, they typically refer to the ability of a CNC machine to move a part or a tool on five different CNC axes at the same time. In addition to the X, Y, and

Ease the machinist effort using CAMWorks

In CAMWorks, you can generate a setup sheet using the existing templates or a customised one. A “setup sheet” is a printable file that contains information that the CNC operator can use to set up the part and the tools

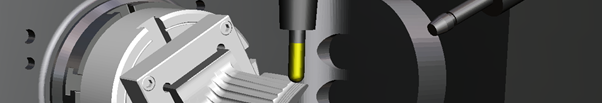

Use CAMWorks Probing for Accurate Results in a short time

Probing has become an established best practice for maximizing the efficiency, quality, capability, and accuracy of machine tools. Standard routines built into modern CNC controls simplify the integration of probing cycles into machining operations. Machine tool probing potentially makes sense

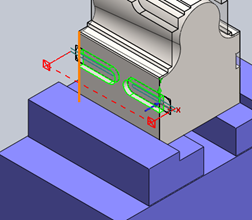

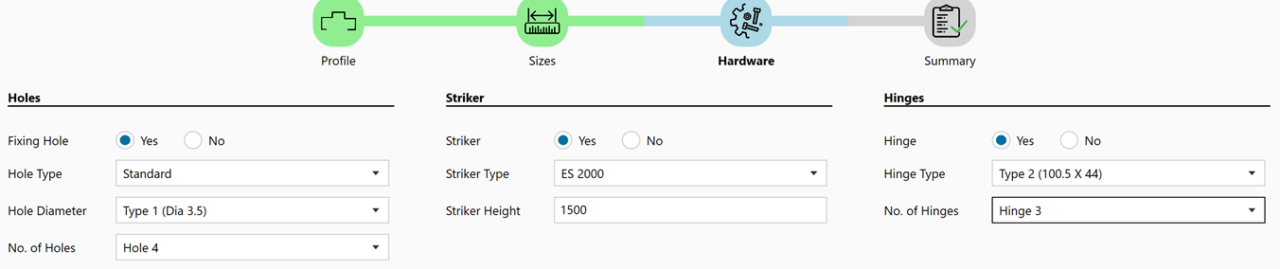

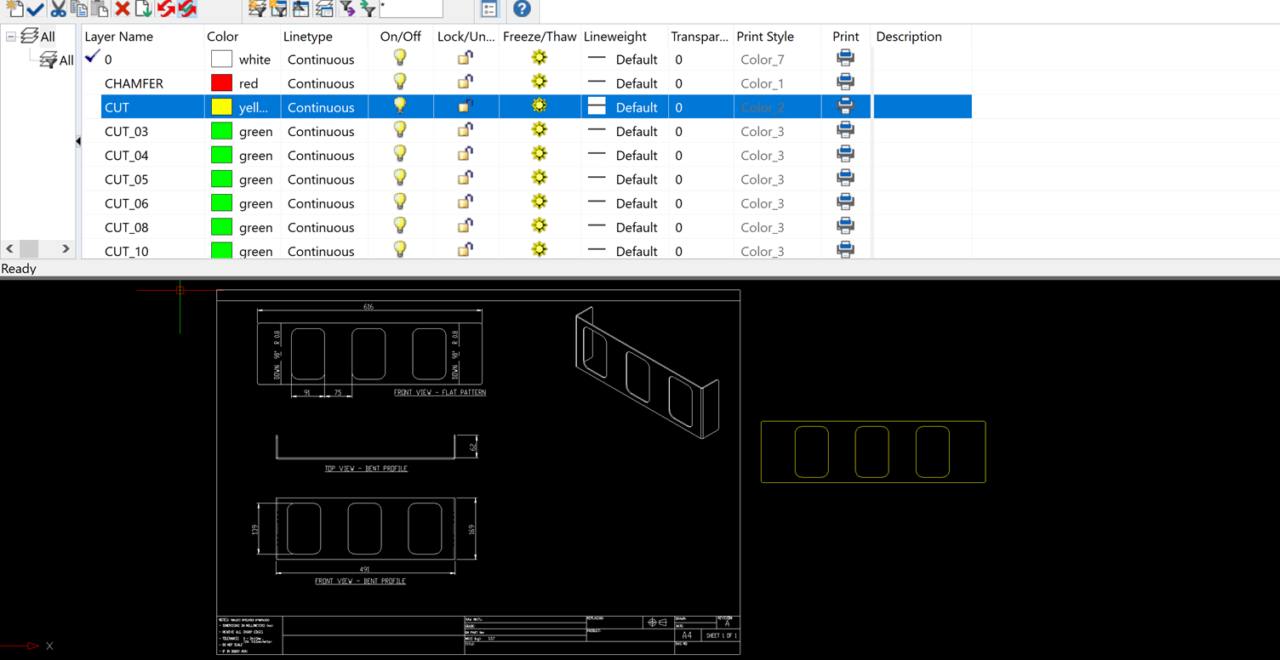

Smart Door Frame Designer Within Few Seconds

Smart Door Frame Designer is unique automation software that reduces the design and manufacturing time of door frames. This helps in customising the design of door frames within a few seconds. This software allows the manufacturer to select a frame

SprutCAM G-code Based Simulation

SprutCAM G-code based simulation allows the consideration of features of the implementation of the postprocessor in the simulation processing. In this mode, the system automatically checks NC code for each operation while calculating machine Kinematics and limits. G-code based simulation function

Time to Update! – CAMWorks 2021

Times are changing and the tool you need are changing with them. CAMWorks 2021 got some new enhancements and additions to improve your programming experience and productivity. Let me list them out for you. Milling Enhancements 5-Axis spiral swarf milling and minimise

Verify G-Code with one click using CAMWorks Virtual Machine

CAMWorks virtual machine performs true G-code machine simulation directly from the G-code used for the CNC machine. CAMWorks is the first CAM software to bring true G-code machine simulation directly integrated within the CNC programming environment. We will discuss some

SprutCAM knife cutting Module

SprutCAM Knife cutting tools are used for cutting of flexible and semi-rigid materials. The CNC machines are equipped with a variety of knife tools and blades. The blade of this cutting tool moves on the surface of the material as per