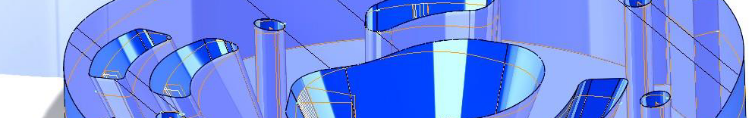

Wire EDM – Salient Features

Wire EDM: 1.Automatic Solid to G-Code in a Single Mouse Click! CAMWorks WireEDM Pro is seamlessly integrated with SOLIDWORKS/CAMWorks Solids and is designed to automatically analyze a selected solid model, generate a machining plan for all its features (2 Axis, 2 Axis

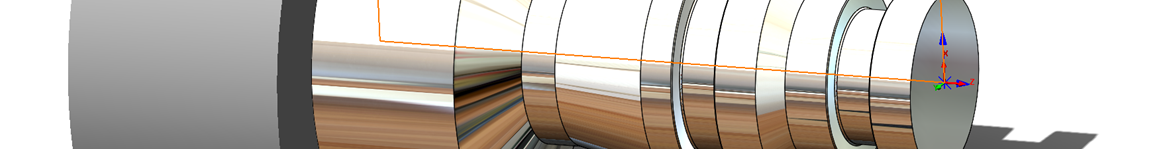

Automatic Feature Recognition For Turning-CAMWorks

Programming for a lathe turning becomes easy and quick when you have CAMWorks. CAMWorks 2 and 4 Axis Turning includes automatic roughing, finishing, grooving, threading, cutoff, and single point (drilling, boring, reaming, and tapping) cycles. CAMWorks turning can be preferred when you need a

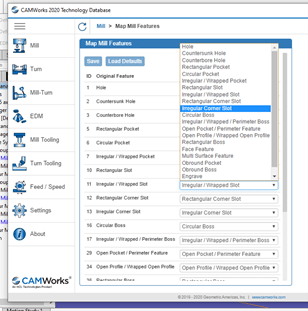

Make your User-defined CAMWorks Database

The intelligence behind CAMWorks machining automation is the Technology Database (TechDB). The Technology Database is shipped with data that is considered generally applicable to most machining environments. To gain full advantage of CAMWorks, you will want to modify this data

Simplify the Shopfloor Collaboration Process

CAMWorks ShopFloor is a newly introduced application in the CAMWorks suite of software products. It serves as a collaboration tool between CAM Programmers (who use the CAMWorks application to generate CAM data for part models and/or assemblies to be machined)

Time to Update! – CAMWorks 2021

Times are changing and the tool you need are changing with them. CAMWorks 2021 got some new enhancements and additions to improve your programming experience and productivity. Let me list them out for you. Milling Enhancements 5-Axis spiral swarf milling and minimise

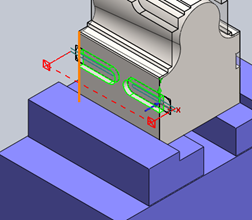

Use CAMWorks Probing for Accurate Results in a short time

Probing has become an established best practice for maximizing the efficiency, quality, capability, and accuracy of machine tools. Standard routines built into modern CNC controls simplify the integration of probing cycles into machining operations. Machine tool probing potentially makes sense

Verify G-Code with one click using CAMWorks Virtual Machine

CAMWorks virtual machine performs true G-code machine simulation directly from the G-code used for the CNC machine. CAMWorks is the first CAM software to bring true G-code machine simulation directly integrated within the CNC programming environment. We will discuss some

Ease the machinist effort using CAMWorks

In CAMWorks, you can generate a setup sheet using the existing templates or a customised one. A “setup sheet” is a printable file that contains information that the CNC operator can use to set up the part and the tools

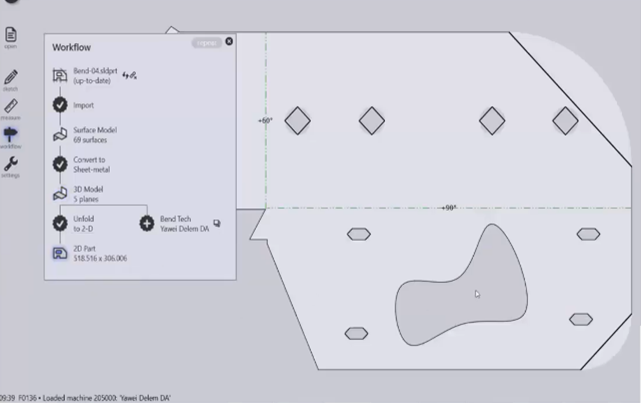

EDM programming – ONE click wire

Are you looking for the best software to run your CNC wire EDM machines that reduces your machining time and gives you accurate results? This is for you! CAMWorks Wire EDM Pro 2021 is an add-in for SolidWorks developed to make

Use CAMWorks 5 Axis Trimming for Clean edges

5 Axis Mill can be used to trim material from parts that have been thermoformed or are composed of composite material. The majority of plastic thermoformers and composite part makers use 5-axis CNC trimming equipment as this is regarded as the