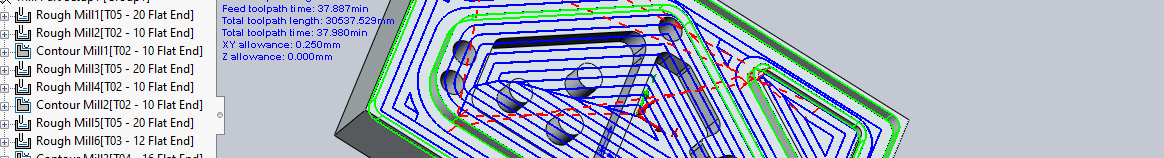

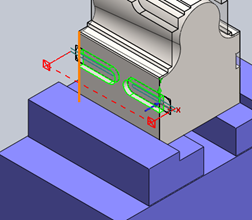

Shorten 2 axis programming times with CAMWorks automation

Here we have a solution for quick and efficient process. 2 Axis milling is a process of milling a part in X and Y directions and the tool motion is along 1 or 2 Axes simultaneously. It is usually a quick

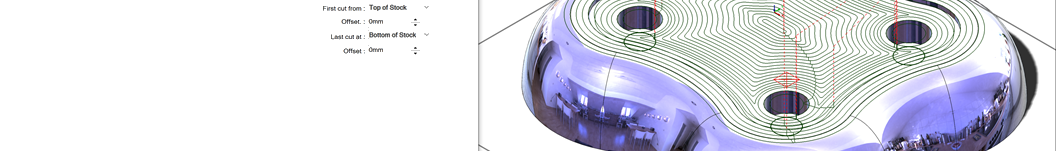

How to Choose Operations for Quicker and More Accurate 3 Axis Programming in CAMWorks

3 Axis milling is the process of milling a part in X, Y and Z directions, and the tool motion is along 1, 2 or 3 Axes simultaneously. It is usually a quick and simple process in CAMWorks. The main advantage

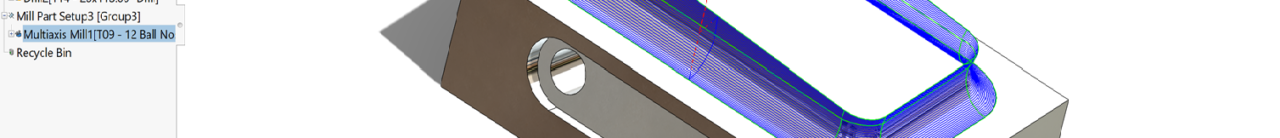

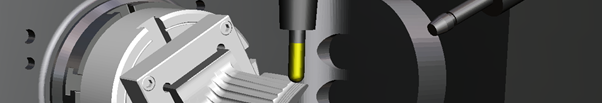

CAMWorks 5-Axis Module for greater machining productivity

When someone uses the term 5-axis machining, they typically refer to the ability of a CNC machine to move a part or a tool on five different CNC axes at the same time. In addition to the X, Y, and

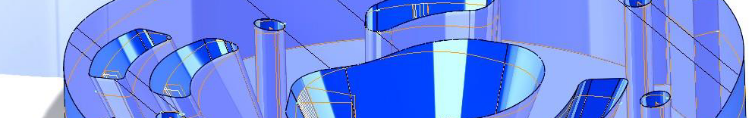

Wire EDM – Salient Features

Wire EDM: 1.Automatic Solid to G-Code in a Single Mouse Click! CAMWorks WireEDM Pro is seamlessly integrated with SOLIDWORKS/CAMWorks Solids and is designed to automatically analyze a selected solid model, generate a machining plan for all its features (2 Axis, 2 Axis

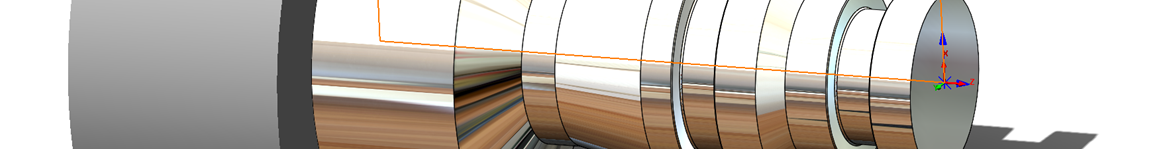

Automatic Feature Recognition For Turning-CAMWorks

Programming for a lathe turning becomes easy and quick when you have CAMWorks. CAMWorks 2 and 4 Axis Turning includes automatic roughing, finishing, grooving, threading, cutoff, and single point (drilling, boring, reaming, and tapping) cycles. CAMWorks turning can be preferred when you need a

Make your User-defined CAMWorks Database

The intelligence behind CAMWorks machining automation is the Technology Database (TechDB). The Technology Database is shipped with data that is considered generally applicable to most machining environments. To gain full advantage of CAMWorks, you will want to modify this data

Simplify the Shopfloor Collaboration Process

CAMWorks ShopFloor is a newly introduced application in the CAMWorks suite of software products. It serves as a collaboration tool between CAM Programmers (who use the CAMWorks application to generate CAM data for part models and/or assemblies to be machined)

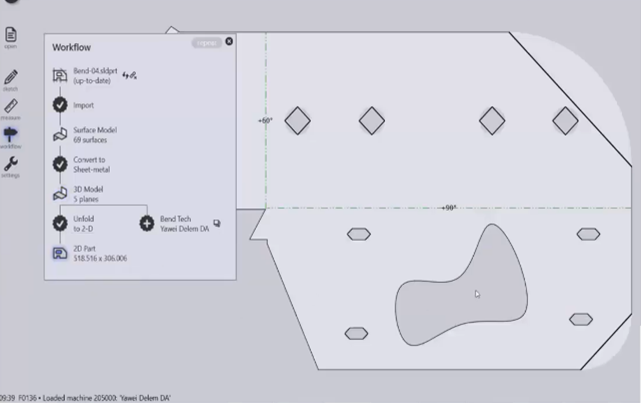

EDM programming – ONE click wire

Are you looking for the best software to run your CNC wire EDM machines that reduces your machining time and gives you accurate results? This is for you! CAMWorks Wire EDM Pro 2021 is an add-in for SolidWorks developed to make

Verify G-Code with one click using CAMWorks Virtual Machine

CAMWorks virtual machine performs true G-code machine simulation directly from the G-code used for the CNC machine. CAMWorks is the first CAM software to bring true G-code machine simulation directly integrated within the CNC programming environment. We will discuss some

SprutCAM G-code Based Simulation

SprutCAM G-code based simulation allows the consideration of features of the implementation of the postprocessor in the simulation processing. In this mode, the system automatically checks NC code for each operation while calculating machine Kinematics and limits. G-code based simulation function