Shorten 2 axis programming times with CAMWorks automation

Here we have a solution for quick and efficient process.

2 Axis milling is a process of milling a part in X and Y directions and the tool motion is along 1 or 2 Axes simultaneously. It is usually a quick and simple process in CAMWorks.

The main advantage of the 2 Axis milling in CAMWorks is that users can mill the part models with lesser number of steps and setups.

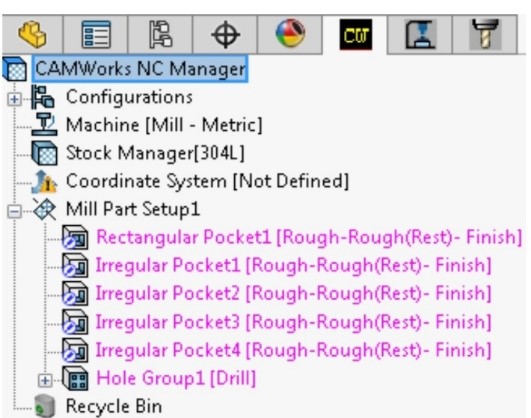

Here we have an option called AFR (Automatic feature recognition) which can cut almost half of the process time. This AFR can automatically recognize the features to be machined by using TechDB. In 2 Axis milling, most of the time AFR is accurate and makes the process quick. We can also manually choose the features to be machined by using ICF (Interactively created features).

The simple few steps for 2 axis milling are listed below,

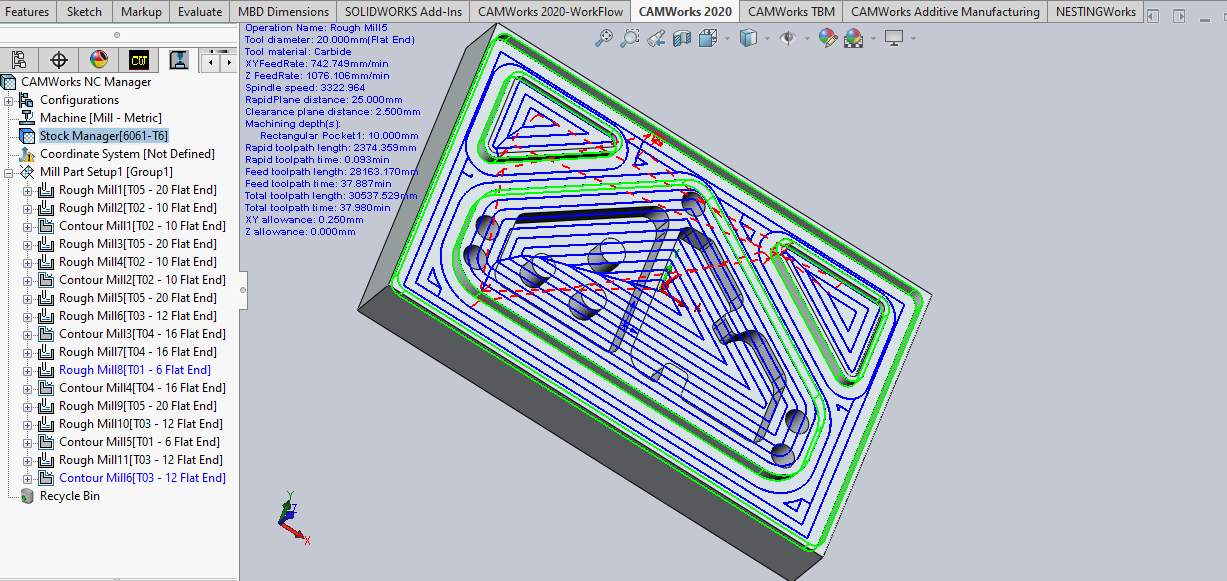

- Define the machine

Here we can select the machine to be used for 2 axis milling (usually Mill-Metric). And we can add, edit, remove and update the tools in the tool crib as per requirements. We can also select the post processing machine during the machine definition.

- Define the stock

This is to define the stock required for milling the part. For milling there are four stock types. We can choose any of the stock types as per requirements. This helps in reducing scraps after machining

- Define the machinable features (AFR or ICF)

We can either extract the machinable features by using AFR or ICF. In some cases, both can be used for defining machinable features.

- Generate the operational plan and adjust if needed.

This is a process to be done before generating toolpath to get the operational plan and we can adjust the parameters if there are any changes or mistakes found.

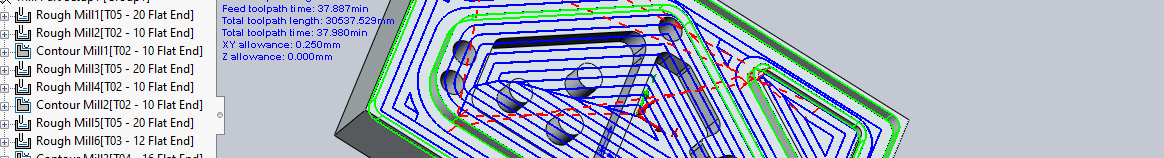

- Generate tool path

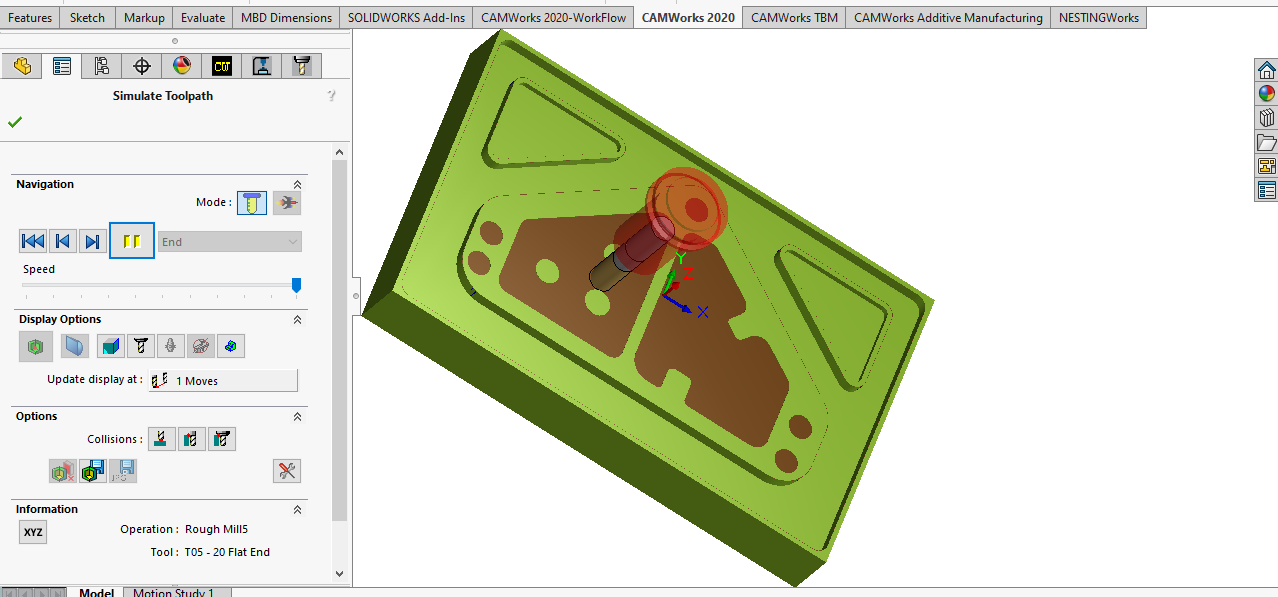

The tool path shows the milling path of each feature.

- Simulate the toolpaths

By simulating the toolpaths, we can be able to visually see what is going to happen in post processing machine. We can adjust the parameters if we found any mistakes during simulation.

- Post process and transmit to CNC

Post processing is the final step in generating the NC program file and setup sheet file. This is a process of converting CAMWorks data in to NC program (G-Code). And Setup Sheet is a printable file that contains information the machine tool operator can use to set up the part and the tools required to produce a part.

Though CAMWorks is user-friendly and self-explanatory, we are here to help, if you got stuck.

For more information on CAMWorks Software and product enquiries visit us at https://nctools.com.au/ or call us on +61 3 8618 6884