CAMWorks® New ShopFloor! Program Smarter – Machine Faster

A Digital Transformation is underway.. And it’s not just Paperless but Digital - Drawings and other documents can be converted to PDF’s (for example) to create “Paperless” environments… but unlike a static PDF. digital information can be analysed and leveraged by

CAMWorks – SolidWorks Designing made easy

About CAMWorks - SolidWorks, Have an idea, but don’t know where to start? We have the perfect solutions for your 2D, 3D modelling, NC machining and even making parts without having to wait for days and months. Our software is user-friendly, self-explanatory

Top 5 time-saving features of CAMWorks 2020

Want to save your programming time? Let’s try CAMWorks 2020. CAMWorks stands unique by saving much of the programming time. Yes, we can be quick and make things done in a few minutes with CAMWorks. Here we discuss the top 5 time-saving

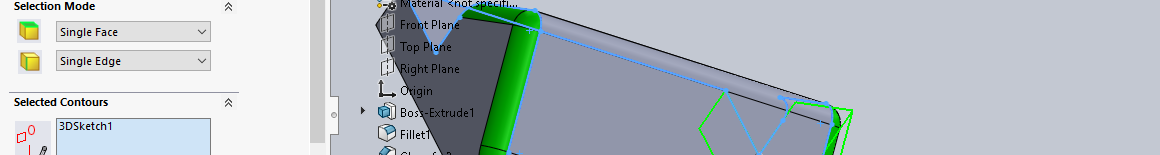

CAMWorks 2020 – New Features

CAMWorks 2020 stands unique by saving much of the programming time. Yes, we can be quick and make things done within few mouse clicks. Here we discuss the 5 more time-saving features of CAMWorks. Probe operations 5 axis volumill 3 axis

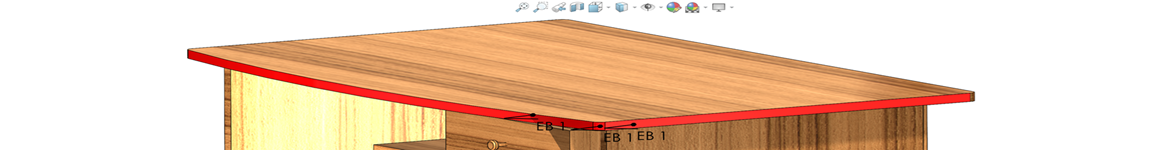

Edgebanding for Solidworks-EdgeWorks Ease the Process

Edgebanding for Solidworks About EdgeWorks - Many users spend a lot of their production time unnecessarily for a few processes such as saving individual DXFs, sorting into groups or materials, applying tool paths in different software, manually nesting components in SOLIDWORKS,

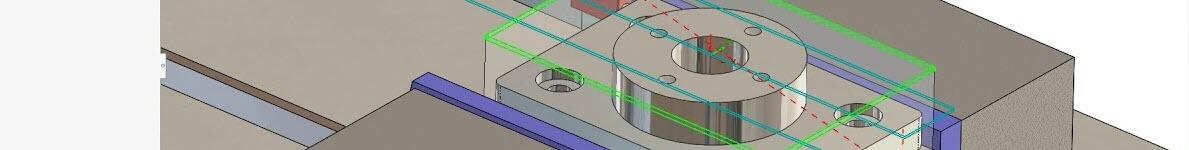

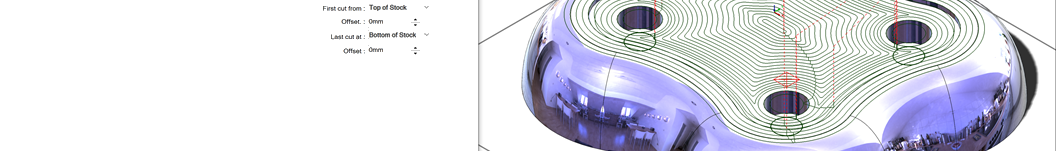

How to Choose Operations for Quicker and More Accurate 3 Axis Programming in CAMWorks

3 Axis milling is the process of milling a part in X, Y and Z directions, and the tool motion is along 1, 2 or 3 Axes simultaneously. It is usually a quick and simple process in CAMWorks. The main advantage

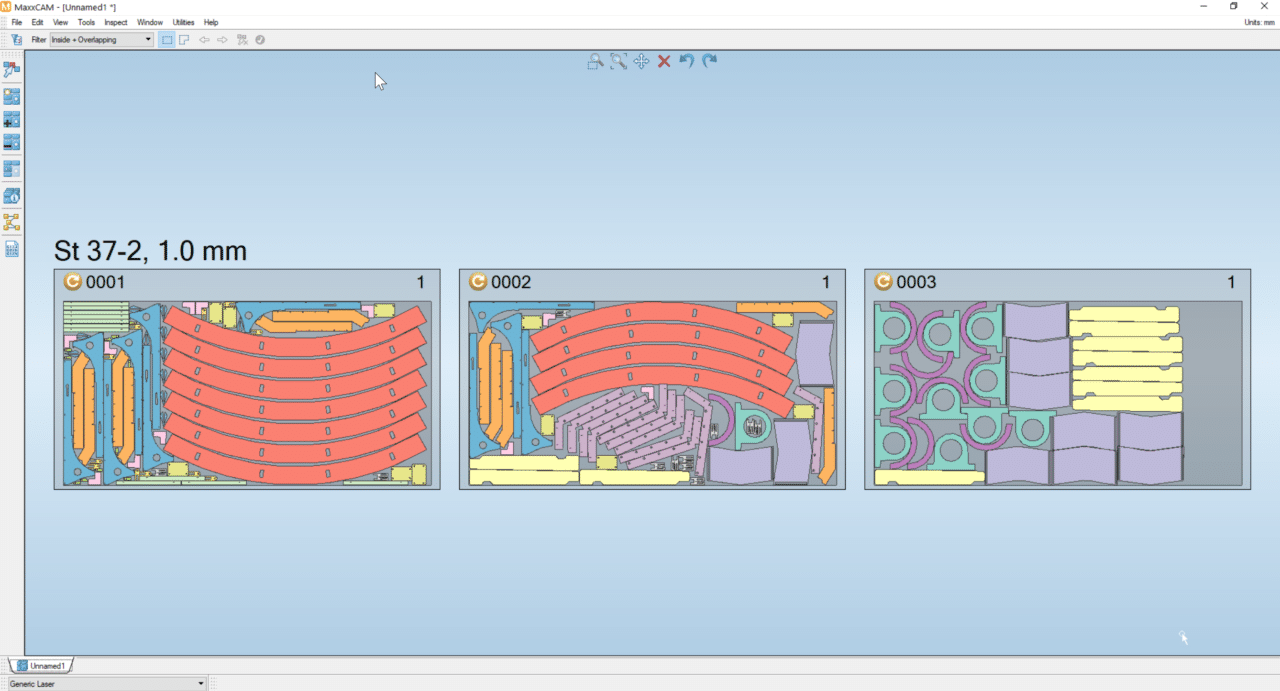

MaxxCAM for optimised Sheet-metal CAM programming

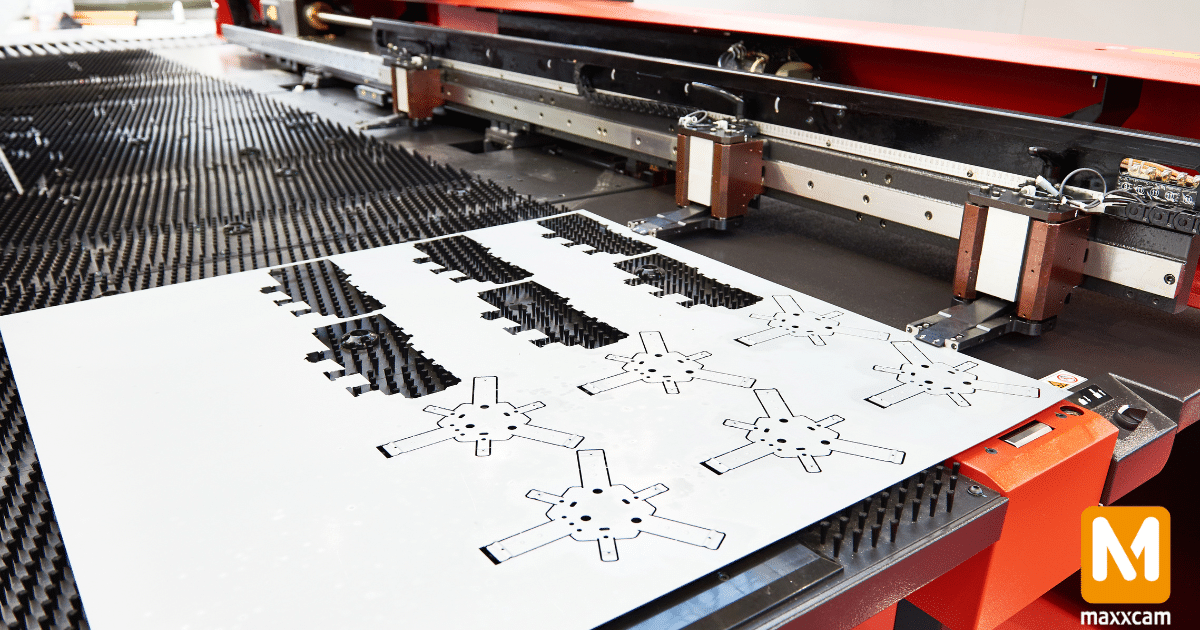

MaxxCAM for optimised Sheet-metal CAM Are you searching for an optimized and time-saving sheet metal CAM software? MaxxCAM is a comprehensive sheet metal CAM software that offers various features, including turret punch, laser cutting, nesting, and more. Let's delve into MaxxCAM's punching capabilities. MaxxCAM

Program your Laser cutting in MaxxCAM Software

MaxxCAM has a comprehensive solution to cater to your laser-cutting needs.( FYI Metacam is trademark owned by We sell MaxxCAM not to be confused we know there are lot of dog lovers out there who get confused with metacam and

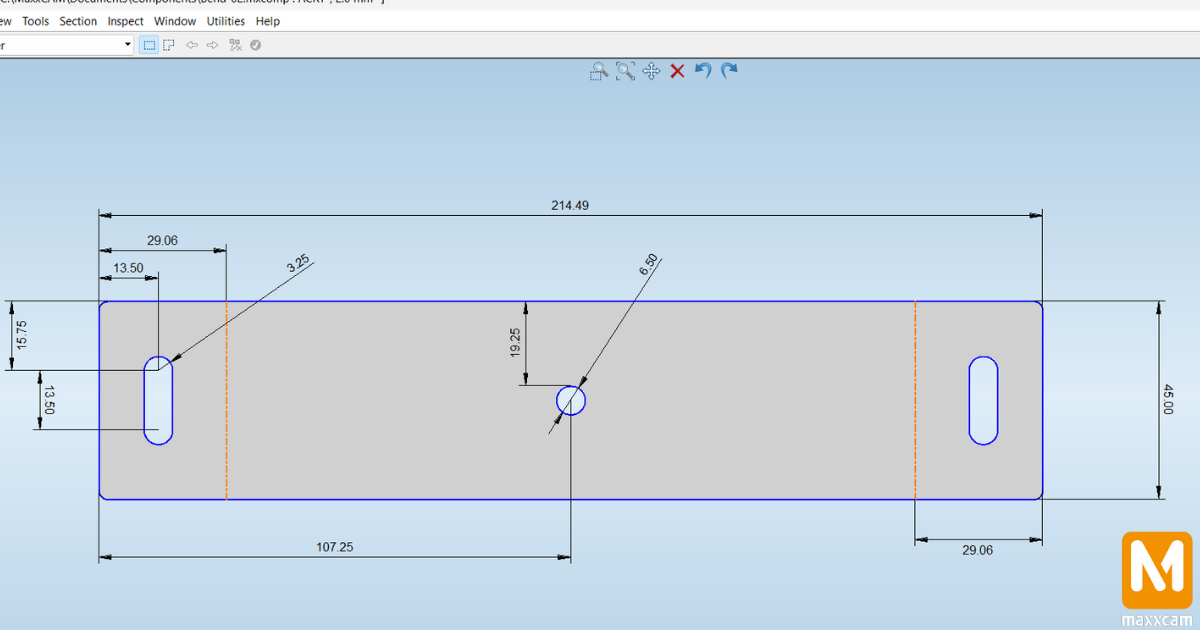

Shorten the Process using MaxxCAM 2D CAD

MaxxCAM's parametric 2D CAD functionality is a powerful feature that empowers users to create and modify designs with ease and precision. This innovative tool within the MaxxCAM software suite streamlines the design process, allowing users to quickly generate accurate and

Use CAMWorks Probing for Accurate Results in a short time

Probing has become an established best practice for maximizing the efficiency, quality, capability, and accuracy of machine tools. Standard routines built into modern CNC controls simplify the integration of probing cycles into machining operations. Machine tool probing potentially makes sense