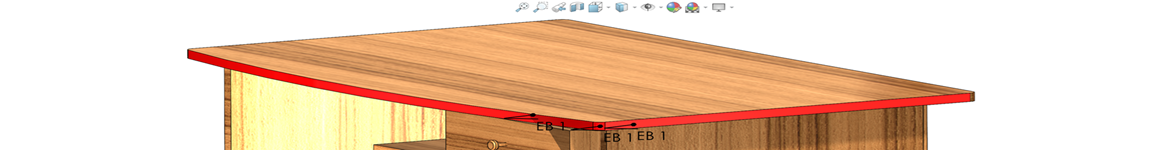

Edgebanding for Solidworks-EdgeWorks Ease the Process

Edgebanding for Solidworks About EdgeWorks - Many users spend a lot of their production time unnecessarily for a few processes such as saving individual DXFs, sorting into groups or materials, applying tool paths in different software, manually nesting components in SOLIDWORKS,

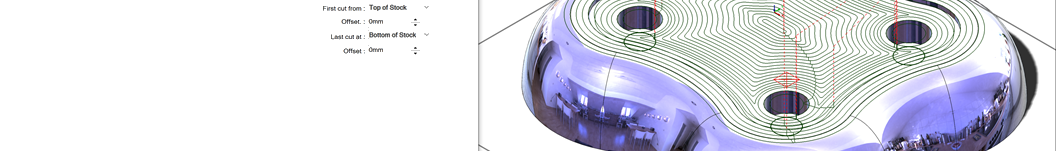

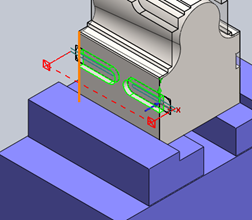

How to Choose Operations for Quicker and More Accurate 3 Axis Programming in CAMWorks

3 Axis milling is the process of milling a part in X, Y and Z directions, and the tool motion is along 1, 2 or 3 Axes simultaneously. It is usually a quick and simple process in CAMWorks. The main advantage

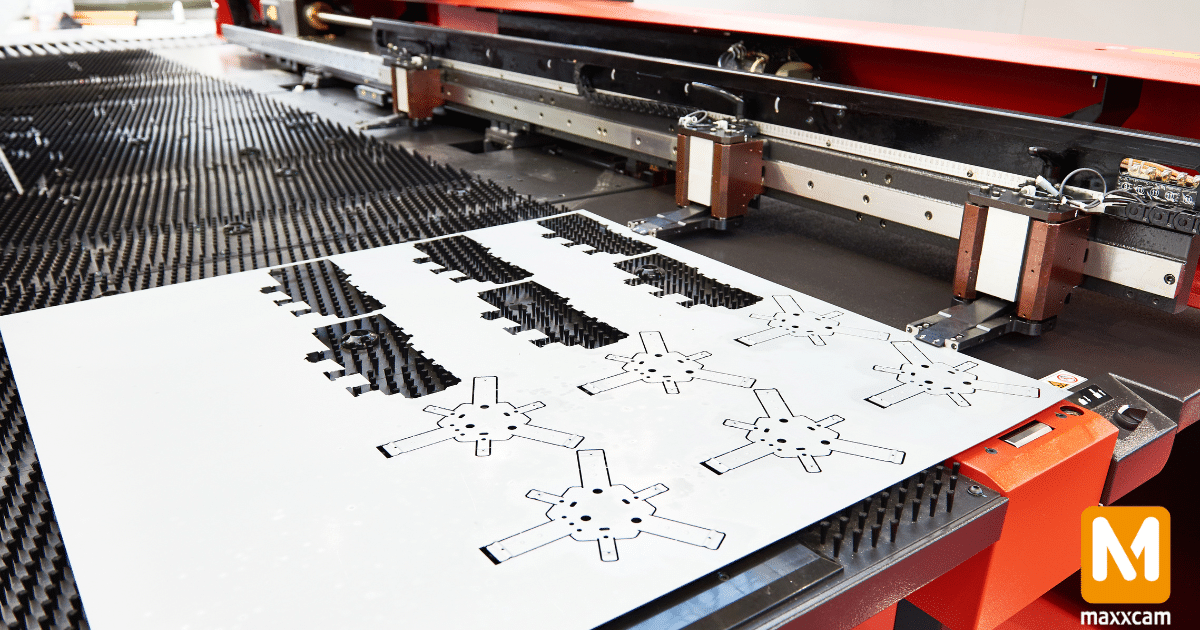

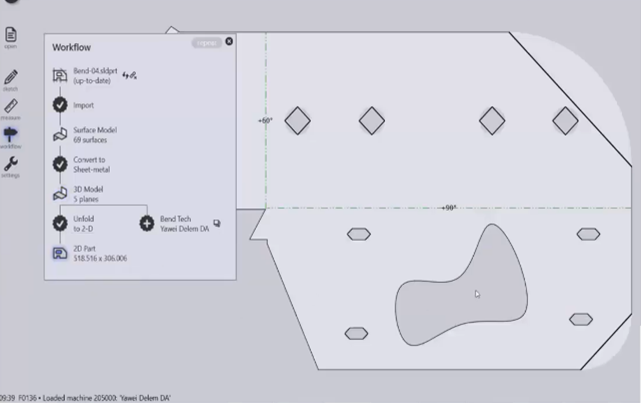

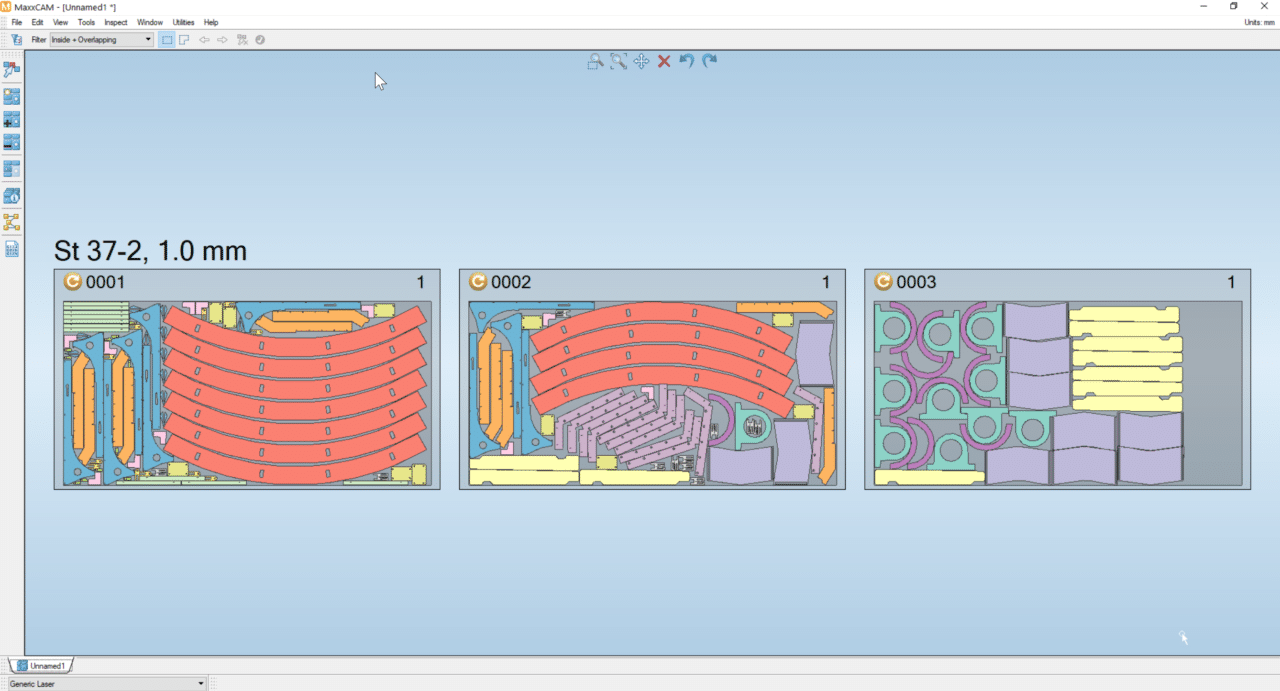

MaxxCAM for optimised Sheet-metal CAM programming

MaxxCAM for optimised Sheet-metal CAM Are you searching for an optimized and time-saving sheet metal CAM software? MaxxCAM is a comprehensive sheet metal CAM software that offers various features, including turret punch, laser cutting, nesting, and more. Let's delve into MaxxCAM's punching capabilities. MaxxCAM

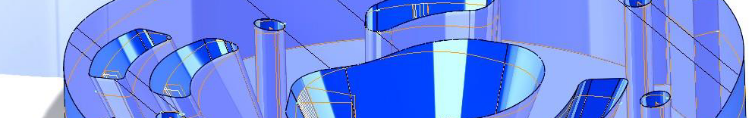

What’s New in CAMWorks 2021

CAMWorks 2021 brings you some interesting updates and additions to the previous version. Let's discuss some of itsinteresting updates and additional features in this blog. • Recognise counter-bolt holes option • Stock options • Probing – 3-pointboss/bore cycle • Define spindle direction for turning and

Wire EDM – Salient Features

Wire EDM: 1.Automatic Solid to G-Code in a Single Mouse Click! CAMWorks WireEDM Pro is seamlessly integrated with SOLIDWORKS/CAMWorks Solids and is designed to automatically analyze a selected solid model, generate a machining plan for all its features (2 Axis, 2 Axis

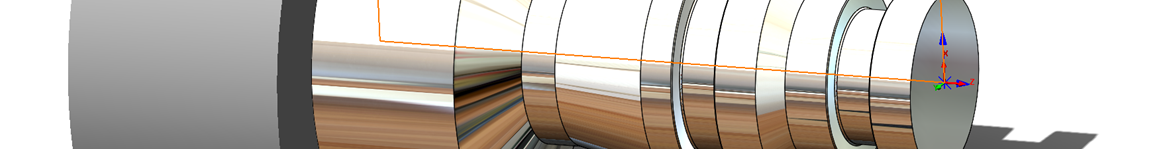

Automatic Feature Recognition For Turning-CAMWorks

Programming for a lathe turning becomes easy and quick when you have CAMWorks. CAMWorks 2 and 4 Axis Turning includes automatic roughing, finishing, grooving, threading, cutoff, and single point (drilling, boring, reaming, and tapping) cycles. CAMWorks turning can be preferred when you need a

Make your User-defined CAMWorks Database

The intelligence behind CAMWorks machining automation is the Technology Database (TechDB). The Technology Database is shipped with data that is considered generally applicable to most machining environments. To gain full advantage of CAMWorks, you will want to modify this data

Simplify the Shopfloor Collaboration Process

CAMWorks ShopFloor is a newly introduced application in the CAMWorks suite of software products. It serves as a collaboration tool between CAM Programmers (who use the CAMWorks application to generate CAM data for part models and/or assemblies to be machined)

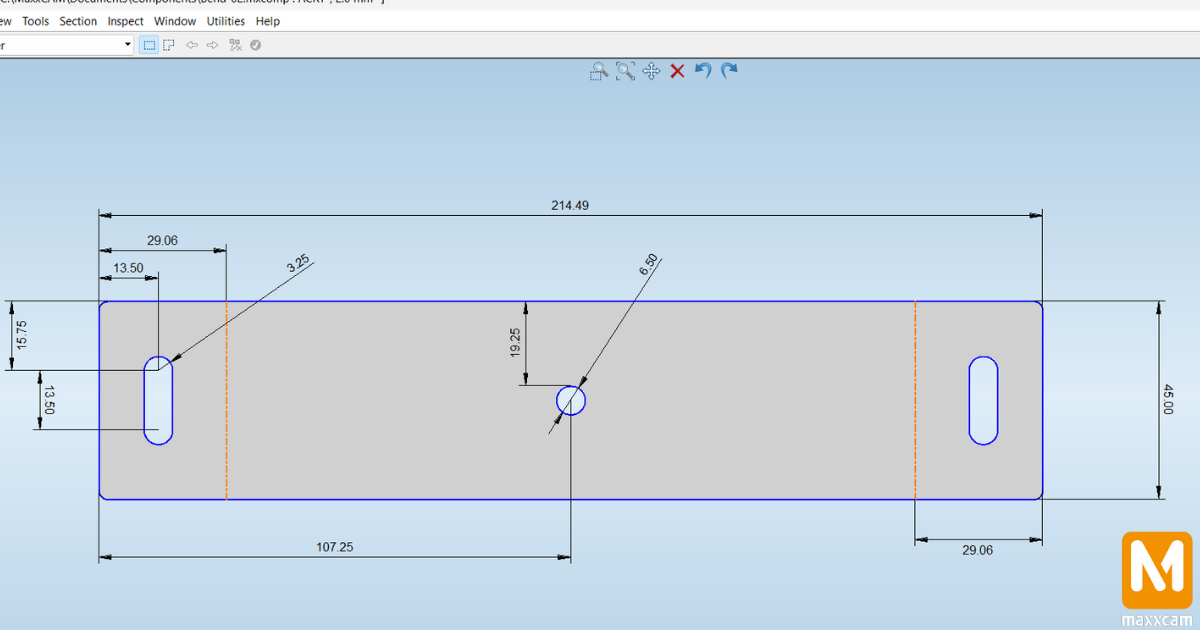

Shorten the Process using MaxxCAM 2D CAD

MaxxCAM's parametric 2D CAD functionality is a powerful feature that empowers users to create and modify designs with ease and precision. This innovative tool within the MaxxCAM software suite streamlines the design process, allowing users to quickly generate accurate and

Program your Laser cutting in MaxxCAM Software

MaxxCAM has a comprehensive solution to cater to your laser-cutting needs.( FYI Metacam is trademark owned by We sell MaxxCAM not to be confused we know there are lot of dog lovers out there who get confused with metacam and