Why SOLIDWORKS users will benefit from NestingWorks

In the past, the only way to carry out the process of Saving DXF for SOLIDWORKS users was to save individual parts as DXF, though some of the Free Macros available can make this process a bit easier. Now, however,

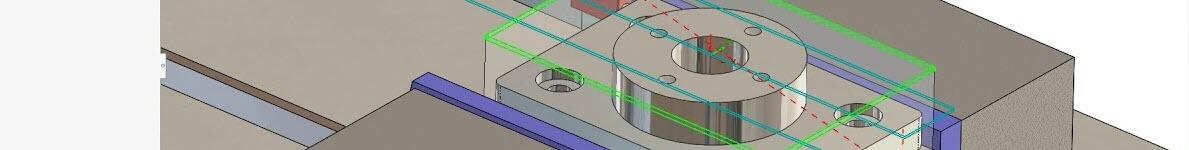

CAMWorks B Axis Functionality for Machining Turn Finish Operations

Introducing CAMWorks Continuous B Axis Functionality for Machining Turn Finish Operations The advantage of this Continuous B Axis Turning functionality is that users can machine the Turn/Mill-Turn part models with a lesser number of setups. In CAMWorks 2020 SP3 version, this

CAMWorks – SolidWorks Designing made easy

About CAMWorks - SolidWorks, Have an idea, but don’t know where to start? We have the perfect solutions for your 2D, 3D modelling, NC machining and even making parts without having to wait for days and months. Our software is user-friendly, self-explanatory

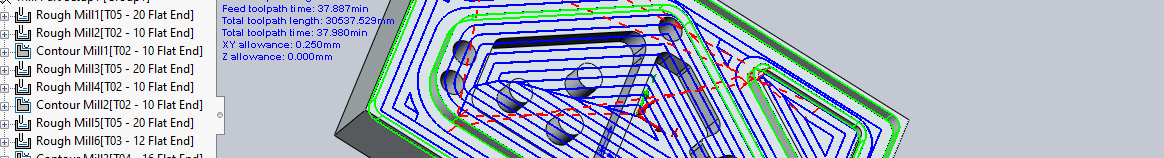

Shorten 2 axis programming times with CAMWorks automation

Here we have a solution for quick and efficient process. 2 Axis milling is a process of milling a part in X and Y directions and the tool motion is along 1 or 2 Axes simultaneously. It is usually a quick

Top 5 time-saving features of CAMWorks 2020

Want to save your programming time? Let’s try CAMWorks 2020. CAMWorks stands unique by saving much of the programming time. Yes, we can be quick and make things done in a few minutes with CAMWorks. Here we discuss the top 5 time-saving

CAMWorks 2020 – New Features

CAMWorks 2020 stands unique by saving much of the programming time. Yes, we can be quick and make things done within few mouse clicks. Here we discuss the 5 more time-saving features of CAMWorks. Probe operations 5 axis volumill 3 axis

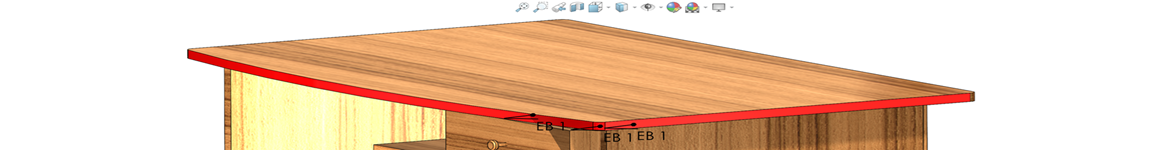

Edgebanding for Solidworks-EdgeWorks Ease the Process

Edgebanding for Solidworks About EdgeWorks - Many users spend a lot of their production time unnecessarily for a few processes such as saving individual DXFs, sorting into groups or materials, applying tool paths in different software, manually nesting components in SOLIDWORKS,

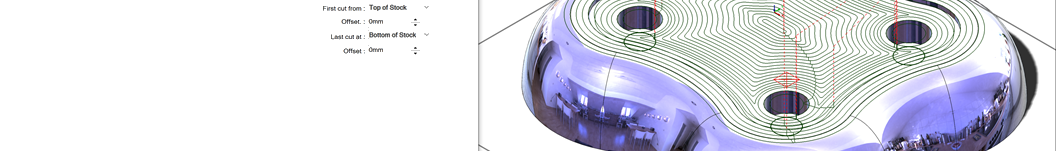

How to Choose Operations for Quicker and More Accurate 3 Axis Programming in CAMWorks

3 Axis milling is the process of milling a part in X, Y and Z directions, and the tool motion is along 1, 2 or 3 Axes simultaneously. It is usually a quick and simple process in CAMWorks. The main advantage

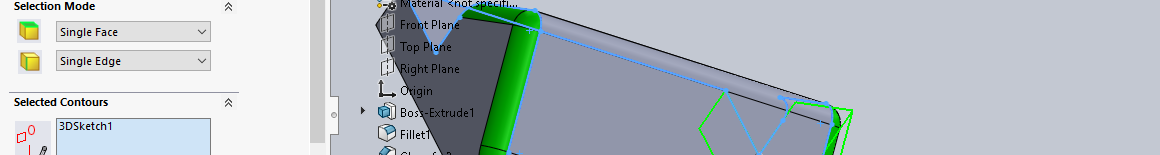

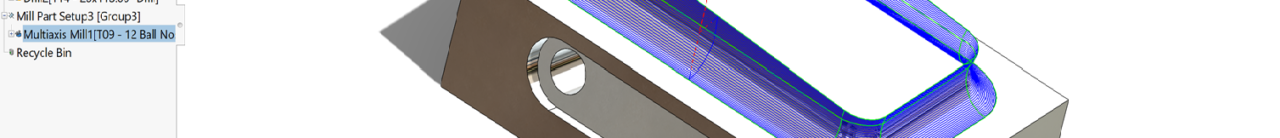

CAMWorks 5-Axis Module for greater machining productivity

When someone uses the term 5-axis machining, they typically refer to the ability of a CNC machine to move a part or a tool on five different CNC axes at the same time. In addition to the X, Y, and

What’s New in CAMWorks 2021

CAMWorks 2021 brings you some interesting updates and additions to the previous version. Let's discuss some of itsinteresting updates and additional features in this blog. • Recognise counter-bolt holes option • Stock options • Probing – 3-pointboss/bore cycle • Define spindle direction for turning and