Do multiple tasks simultaneously with SprutCAM

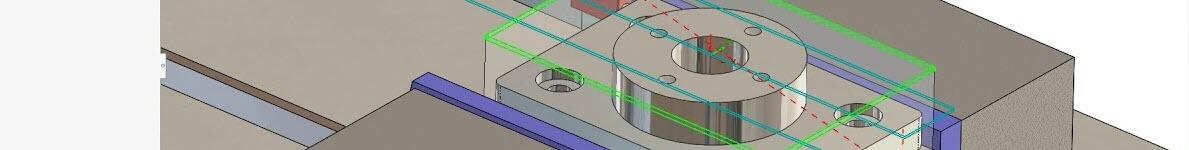

Machines that perform multiple tasks simultaneously are known as multitasking machines (MTM). MTM can vary greatly. As an example, a multi-task turn-milling centre typically has several spindles or/and turret heads inside one housing. In some cases, a multi-task machine consists of two or more identical machines that share a single workpiece.

Multi-task Turn Milling Centre

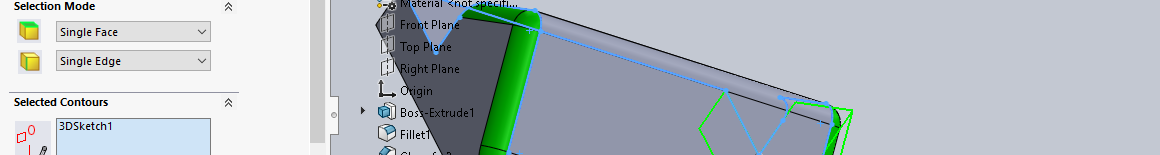

In multitask machining, each tool is controlled by its own program. The program is known as a channel of control. In other words, the multitasking machine has multiple channels.

Programming a multichannel machine is the same as programming a single-channel machine on the Machining page. Users should be aware that the operation tool holder defines the channel

There is a button to choose the simulation mode on the Simulation page for the multitask machines:

In the single-channel simulation mode, the simulation is performed one step at a time. With this mode, it is possible to analyse the tool path of a separate operation without having to take into account the other channels.

As in multichannel mode, the simulation is executed simultaneously on each channel as it would be on the actual equipment. By using this mode, it is easy to check for collisions while taking into account the motions in all channels. The addition of sync points can eliminate collisions detected.

Silk lines provide an easy means of adding, removing, and editing sync points in multichannel mode.

Sync points

In sync points, the execution of one channel is suspended until another channel arrives at a particular block. The sync points in many CNC machines are coded using M-codes.

For more information on SprutCAM Software and product inquiries, visit us at https://nctools.com.au/ or call us on +61 3 8618 6884