What’s New in SprutCAM 15

As times change, so do the tools you need. A number of enhancements and additions have been made to SprutCAM 15 to enhance your programming experience. Here is a list of them. Multi-parts projects/Tombstone machining The possibility of machining several

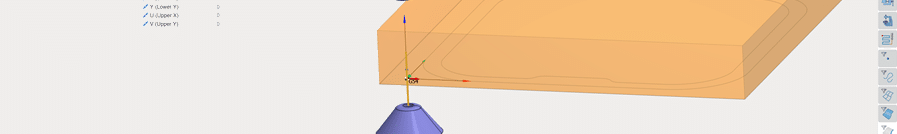

Create parametric 3d models and program with SprutCAM 15

SprutCAM is a new-generation software program that works directly with imported CAD data, automatically generating toolpaths that are able to be simulated graphically. Through the introduction of SprutCAM 15, users will now be able to create 3D drawings by utilizing

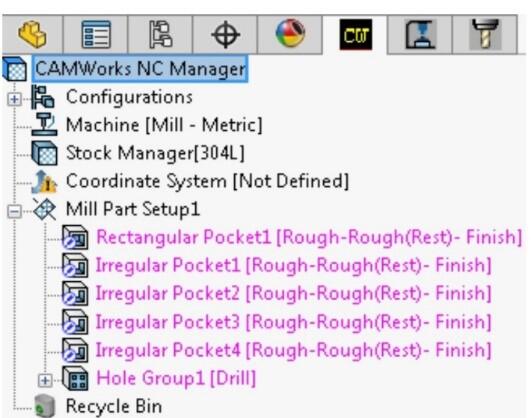

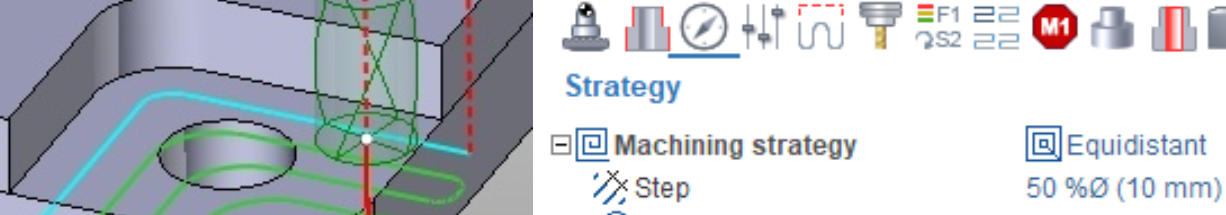

Automate your manufacturing process with Feature-based machining (FBM)

Automate your manufacturing process A key function of manufacturing process planning is the planning of machining sequences. The term Manufacturing Feature refers to a component of a part that can be manufactured using a standard machining process. Holes, pockets, slots, grooves,

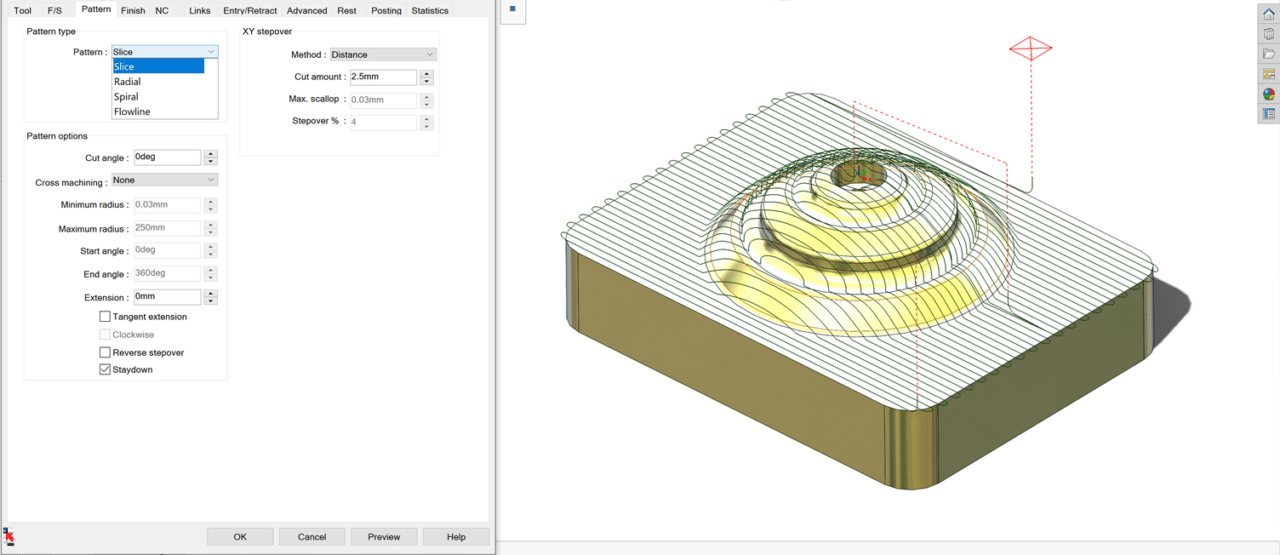

SprutCAM Spiral Face Milling

SprutCAM adaptive face milling minimizes the cycle time for facing operations: In contrast to regular face milling, SprutCAM utilizes adaptive face milling to enhance the machining strategy. The focus is on reducing cycle time through tool paths. The tool path

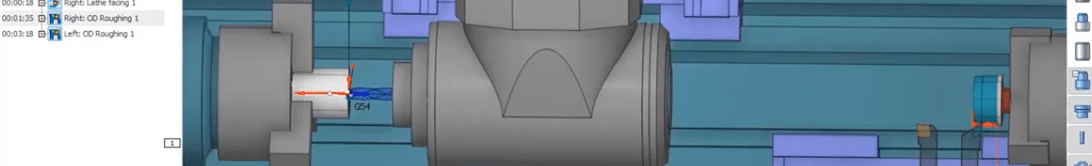

How does a Mill-Turn machine work?

The Mill Turn machine is a hybrid CNC machine. Mill/Turn incorporates the advantages of both turning and milling in one operation. In order to understand how a Turn Mill machine functions, you must first understand the principles of turning and milling.

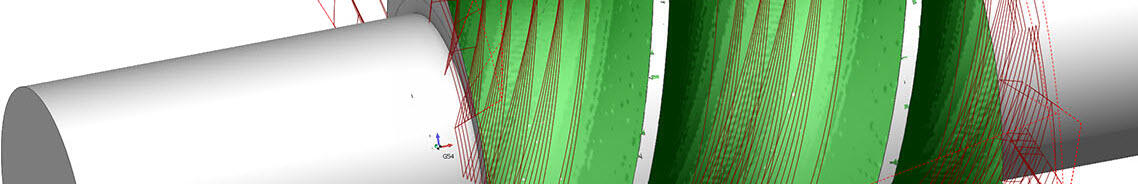

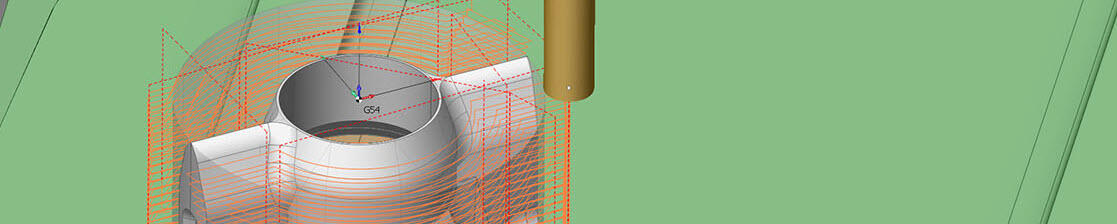

SprutCAM’s Adaptive Roughing

SprutCAM’ s adaptive roughing strategy makes optimal use of machine tools and cutting capabilities to increase roughing processes' productivity and efficiency. A consistent tool engagement results in smooth toolpath motion, resulting in improved material removal rates, reduced cycle times, and

SprutCAM Advanced Features

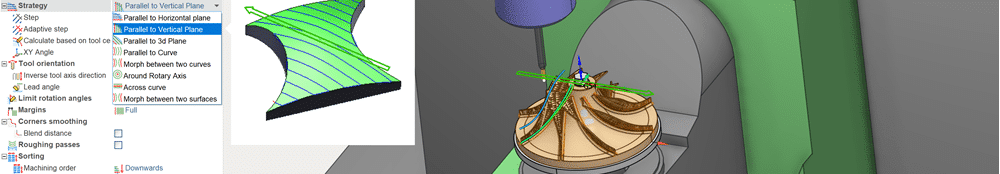

SprutCAM’ s Multiaxis toolpath contains extensive strategies for controlling toolpaths and tool axes SprutCAM offers the most comprehensive set of 5 axis machining strategies available today, as well as an adequate technology solution that can take on any 5 axis machining

SprutCAM EDM Machining

With SprutCAM's wire EDM machining, SprutCAM EDM can produce curvilinear contours in 2 and 4 dimensions. EDM is an electrical discharge machining process that is primarily used for machining applications involving this process. In this device, a current is transmitted between

High-performance cutting with SprutCAM

Sprut HPC is a high performance cutting strategy designed for efficient removal of material from both open and closed pockets. The following operations support this strategy. Rough waterline Pocketing Pocketing 2.5D Flat land finishing You can select this strategy from the option

Why Manufacturing companies need 5 axis Machines

Programming with SprutCAM’ S 5 axis: Currently, a significant number of manufacturers are interested in Multiaxis machining. Generally, this is because it will be a single solution for all types of machining. There are a wide range of advantages associated with