EDM programming – ONE click wire

Are you looking for the best software to run your CNC wire EDM machines that reduces your machining time and gives you accurate results? This is for you! CAMWorks Wire EDM Pro 2021 is an add-in for SolidWorks developed to make

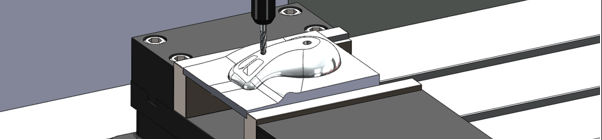

Use CAMWorks 5 Axis Trimming for Clean edges

5 Axis Mill can be used to trim material from parts that have been thermoformed or are composed of composite material. The majority of plastic thermoformers and composite part makers use 5-axis CNC trimming equipment as this is regarded as the

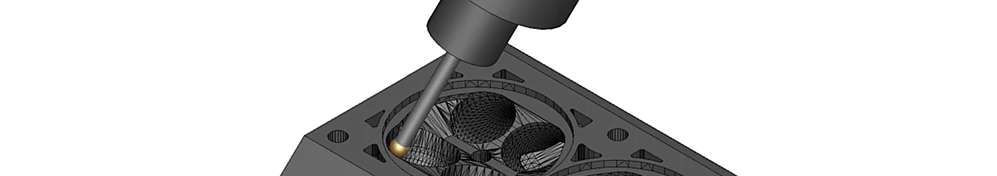

Multi Axis operations with CAMWorks – Port Machining

Port Machining is a common strategy with 5 axis machining to machine the inside of an intake or exhaust channels and other ports. In this blog, we will see the procedure to set this up. This can be done quickly

SolidworkCAM vs CAMWorks

Have you outgrown SOLIDWORKSCAM in your machine shop? Consider upgrading to CAMWorks - The SOLIDWORKSCAM is an add-in to Solidworks CAD. With Solidworks CAM, we are able to program SOLIDWORKS parts directly into G-Code to drive a CNC machine. In order

Tolerance Based Machining (TBM) with CAMWorks

In addition to CAMWorks AFR for identifying manufacturing features and automating the creation of tool paths. In addition, CAMWorks introduced features for recognizing dimensions, tolerances, and surface finish annotations associated with models. Camworks' tolerance based machining can recognize Solidworks dimensions,

Introducing CAMWorks 2022

CAMWorks 2022 delivers the performance improvements you need so you can get your work done faster! CAMWorks constantly updates its software to satisfy the requirements of the manufacturing industry, as well as offering features to assist manufacturers through its software. A

CADCAM software is essential for modern CNC shops

CAD The design phase is the beginning of any manufacturing process. If you do not have a CAD model design, manufacturing a part will be very difficult or we might say that it is not efficient to carry out the production

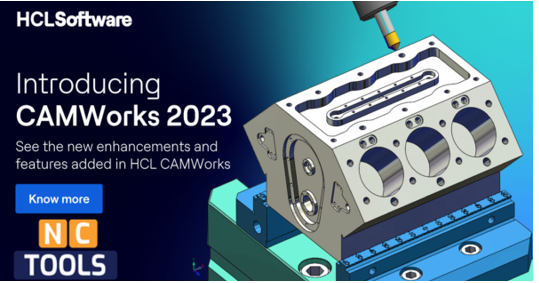

CAMWorks 2023, CAD CAM software Australia New Zealand Update

CAMWorks 2023′ integrated features allow you to program smarter and machine faster CAD/CAM, feature-based programming, automatic feature recognition, knowledge-based machining, and the TechDB to save and reuse best practices. A number of new features have been added to HCL CAMWorks 2023

How to generate G-code using CAMWorks/Solidworks CAM inside SolidWorks, follow these steps

Design your part: Make a 3D model of your part in SolidWorks. Be sure all dimensions and features are accurate, as well as that it is properly defined. Set up machining operations: Open the CAMWorks add-in in SolidWorks. Go to the CAMWorks tab

WHAT DO YOU KNOW ABOUT CAMWORKS?

KNOW ABOUT CAMWORKS?- CAMWorks is the first CAM software product to be certified as a SolidWorks Gold product. CAMWorks is an integrated CAD/CAM solution for CNC machines. It could also be said that CAMWorks bridges the manufacturing process of CNC