SolidworkCAM vs CAMWorks

Have you outgrown SOLIDWORKSCAM in your machine shop?

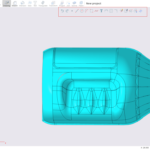

Consider upgrading to CAMWorks – The SOLIDWORKSCAM is an add-in to Solidworks CAD. With Solidworks CAM, we are able to program SOLIDWORKS parts directly into G-Code to drive a CNC machine. In order to remain on the leading edge of technology, CAMWorks introduced Automatic Feature Recognition (AFR) and Interactive Feature Recognition (IFR). CAMWorks provides automatic machining results, and with its advance feature recognition, changes to a part model after generating CAM can be modified, and the modifications and changes will be automatically updated while the output is being produced. The integration of CAD and CAM software together simplifies the process significantly.

Alternatively, the process would require creating a 3D model and generating G-Codes respectively in each software separately and modifying the entire process sequence would require the entire procedure to be repeated from beginning to end.

Below or the foremost points of SolidworkCAM & CAMWorks:

1. Knowledge based machining

Customers can customise the software according to the needs of their manufacturing processes. The technology database, also known as TechDB, allows the user to modify and fully utilise knowledge-based machining. Additionally, TechDB saves the custom machining strategies for future use.

2. Automatic Feature Recognition (AFR)

Identify the prismatic feature of the part in order to develop a machine strategy to reduce cycle time. Additionally, this feature will update if the part is modified in any way.

3. Advanced 3D feature-based machining

By selecting a multisurface feature and IFR, the programming of the complex can be simplified.

4. Seamless integration to CAD

If there is a change required to be made to the finished product during the CAM process, it may be made directly within the same platform. This reduces common problems such as design changes or file compatibility issues.

5. High productivity toolpath

CAMWorks’ high-performance roughing module combines optimal milling paths and minimum machining times with maximum material removal. The machines run smoothly and the tools operate at a lower temperature.

6. Simulation of tool path and machining output

Before executing a program in real time, a tool collision simulation can be executed to verify tool movement, machining, and tool collision. As a result, tool damage will be avoided, material waste will be reduced, and time will be saved.

CAMWorks is the first Solidworks gold-certified product for manufacturing/CAM software integration into the design software. Though Solidworks CAM is powered by CAMWorks, Solidworks CAM contains only the primary versions of CAM add-ons. The features are exclusive to CAMWorks

For more information on CAMWorks Software and product enquiries, visit us at https://www.nctools.com.au/or call us on +61 3 8618 6884.