Make your User-defined CAMWorks Database

The intelligence behind CAMWorks machining automation is the Technology Database (TechDB). The Technology Database is shipped with data that is considered generally applicable to most machining environments. To gain full advantage of CAMWorks, you will want to modify this data

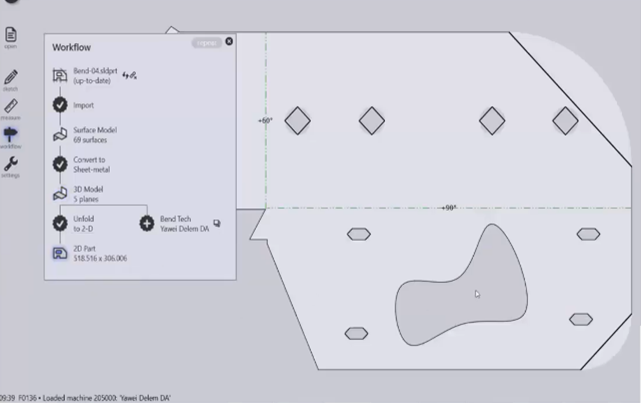

Simplify the Shopfloor Collaboration Process

CAMWorks ShopFloor is a newly introduced application in the CAMWorks suite of software products. It serves as a collaboration tool between CAM Programmers (who use the CAMWorks application to generate CAM data for part models and/or assemblies to be machined)

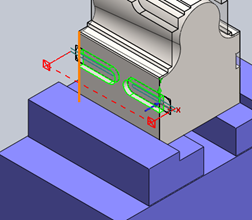

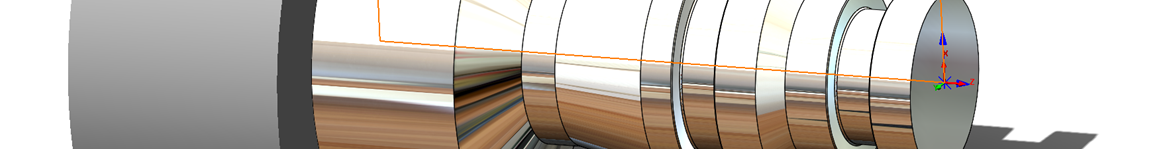

Automatic Feature Recognition For Turning-CAMWorks

Programming for a lathe turning becomes easy and quick when you have CAMWorks. CAMWorks 2 and 4 Axis Turning includes automatic roughing, finishing, grooving, threading, cutoff, and single point (drilling, boring, reaming, and tapping) cycles. CAMWorks turning can be preferred when you need a

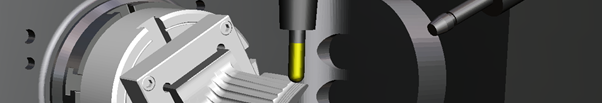

Verify G-Code with one click using CAMWorks Virtual Machine

CAMWorks virtual machine performs true G-code machine simulation directly from the G-code used for the CNC machine. CAMWorks is the first CAM software to bring true G-code machine simulation directly integrated within the CNC programming environment. We will discuss some

CNC shop – ready to embrace a Digital Twin?

CNC shop - A digital twin is a digital version of your CNC machine inside your CAM Software. A digital twin is not just limited to your tool simulation. An accurate kinematic model of your CNC machine, including travel limits,