How to Choose Operations for Quicker and More Accurate 3 Axis Programming in CAMWorks

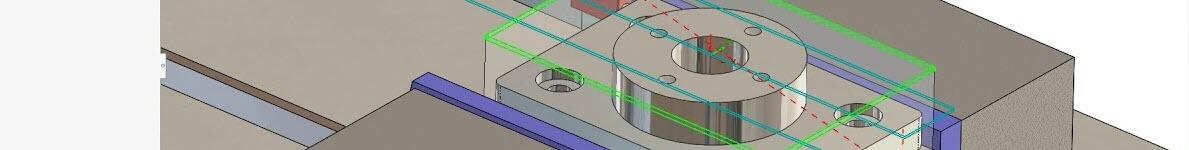

3 Axis milling is the process of milling a part in X, Y and Z directions, and the tool motion is along 1, 2 or 3 Axes simultaneously. It is usually a quick and simple process in CAMWorks.

The main advantage of 3 Axis milling in CAMWorks is that users can mill the part models with a smaller number of steps and setups and with more accuracy.

We can use Automatic Feature Recognition (AFR) or manually choose the operations to program 3 Axis milling.

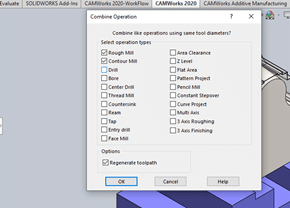

There are many types of 3 Axis mill Operations CAMWorks

- Area clearance

- Pattern project

- Z level

- Flat area

- Curve project

- Constant stepover

- Pencil mill

Area Clearance

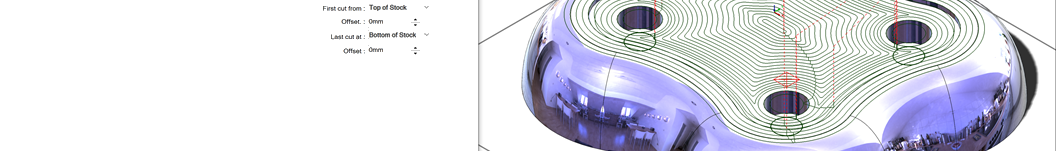

The Area Clearance option is used to remove the material between the stock and the selected feature at desired Z -depth levels by making a series of parallel cuts across the stock or by pocketing out toward the stock.

Pattern Project

The Pattern Project operation is a multi-surface finishing feature that removes material based on the selected pattern: Slice, Radial, Spiral and Flowline.

Z-Level

The Z -Level operation removes the material by making a series of horizontal planar cuts. The cuts generally follow the contour of the feature at decreasing Z levels based on the specified Surface Finish.

Flat Area

The Flat Area operation uses a pocket-out pattern to remove material from feature faces that are flat and parallel to the XY machining plane. In this operation, CAMWorks generates toolpaths only for completely flat areas.

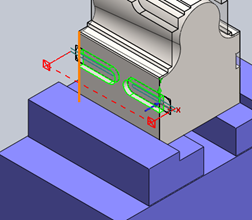

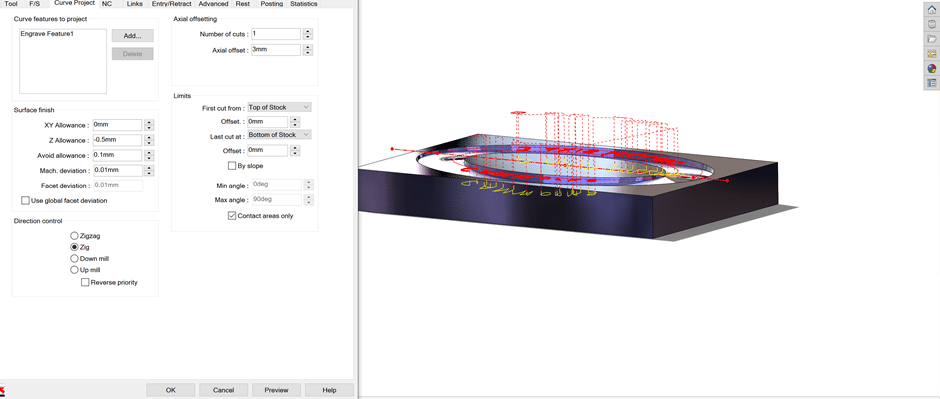

Curve Project

The Curve Project operation removes the material by selecting curve features on the faces or surfaces of a multi-surface feature and generating toolpaths along the selected curve or entities.

Constant Stepover

The Constant Stepover operation removes material by maintaining a constant user-defined stepover relative to the surface.

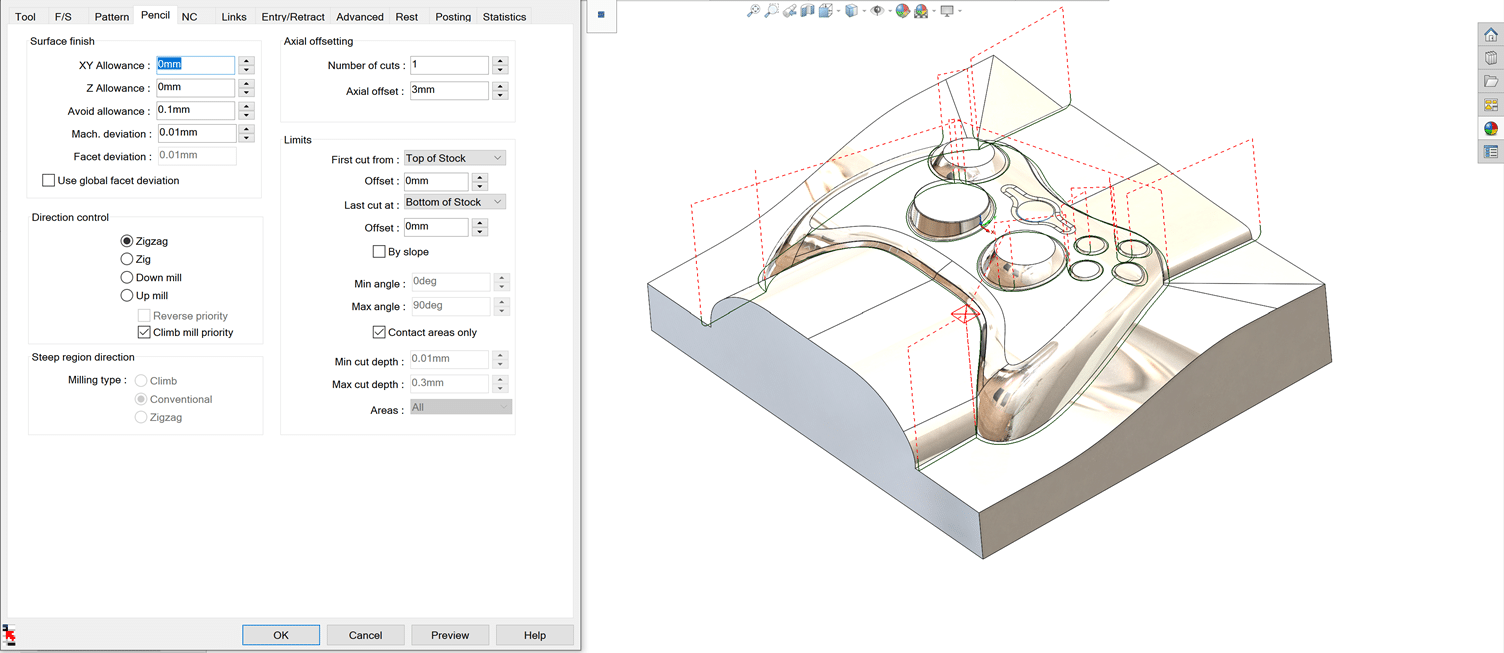

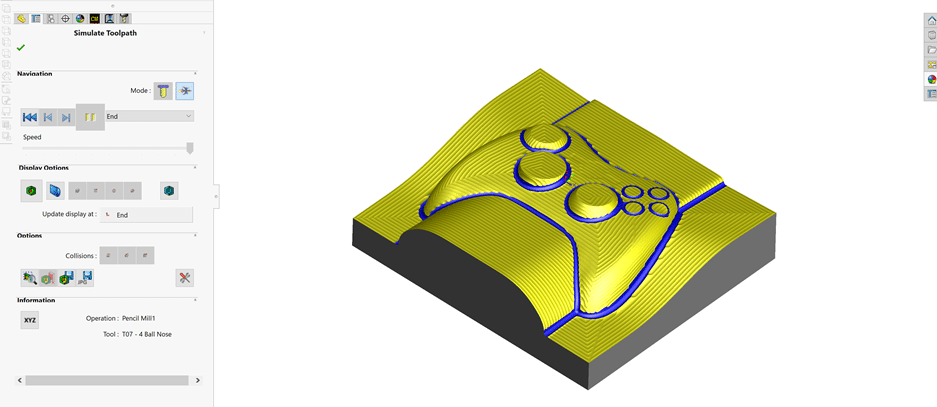

Pencil Mill

The Pencil Mill operation generates toolpaths to finish the machined corner areas by using a single pass or multiple Constant Stepover passes.

Though CAMWorks is user-friendly and self-explanatory, we are here to help, if you get stuck.

For more information on CAMWorks Software and product enquiries visit us at https://nctools.com.au/ or call us on +61 3 8618 6884