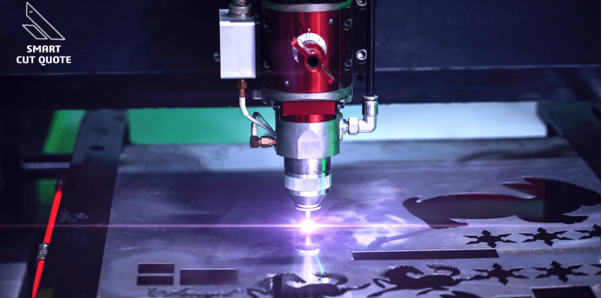

MaxxCAM – Quick Nesting with Maximum Material Utilisation

MaxxCAM – Optimize Material Utilization with Quick Nesting MaxxCAM nesting software features a powerful nesting engine equipped with dedicated algorithms for Punch, Profile, Punch/Shear, and more. These algorithms ensure maximum material utilization based on your specific requirements. Nesting with MaxxCAM: Start

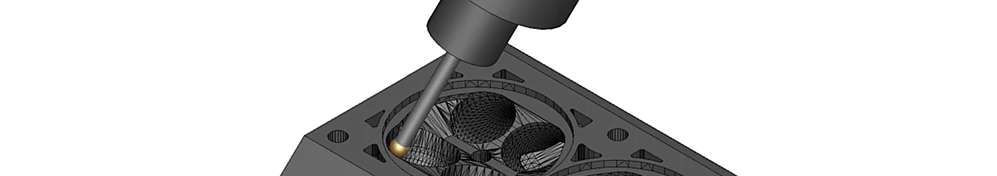

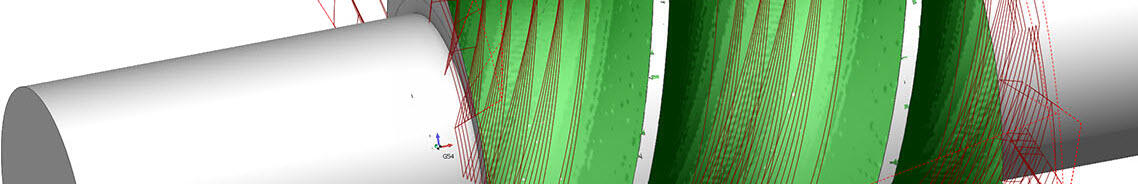

Multi Axis operations with CAMWorks – Port Machining

Port Machining is a common strategy with 5 axis machining to machine the inside of an intake or exhaust channels and other ports. In this blog, we will see the procedure to set this up. This can be done quickly

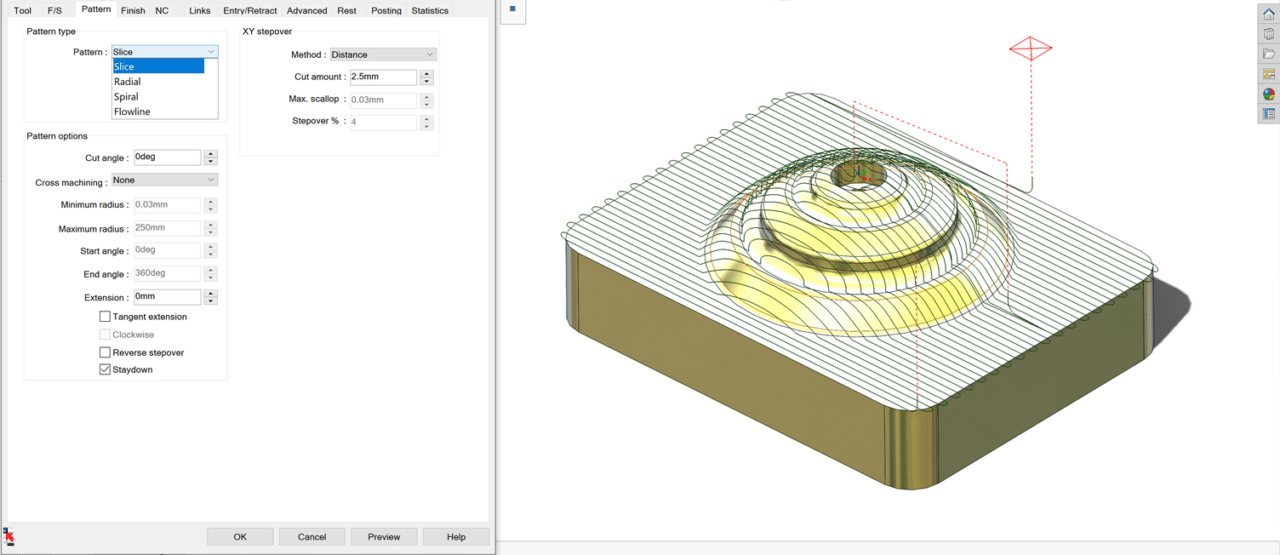

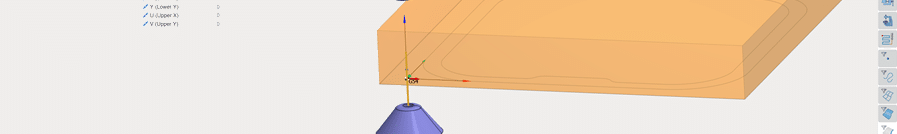

SprutCAM Spiral Face Milling

SprutCAM adaptive face milling minimizes the cycle time for facing operations: In contrast to regular face milling, SprutCAM utilizes adaptive face milling to enhance the machining strategy. The focus is on reducing cycle time through tool paths. The tool path

How does a Mill-Turn machine work?

The Mill Turn machine is a hybrid CNC machine. Mill/Turn incorporates the advantages of both turning and milling in one operation. In order to understand how a Turn Mill machine functions, you must first understand the principles of turning and milling.

SolidworkCAM vs CAMWorks

Have you outgrown SOLIDWORKSCAM in your machine shop? Consider upgrading to CAMWorks - The SOLIDWORKSCAM is an add-in to Solidworks CAD. With Solidworks CAM, we are able to program SOLIDWORKS parts directly into G-Code to drive a CNC machine. In order

SprutCAM’s Adaptive Roughing

SprutCAM’ s adaptive roughing strategy makes optimal use of machine tools and cutting capabilities to increase roughing processes' productivity and efficiency. A consistent tool engagement results in smooth toolpath motion, resulting in improved material removal rates, reduced cycle times, and

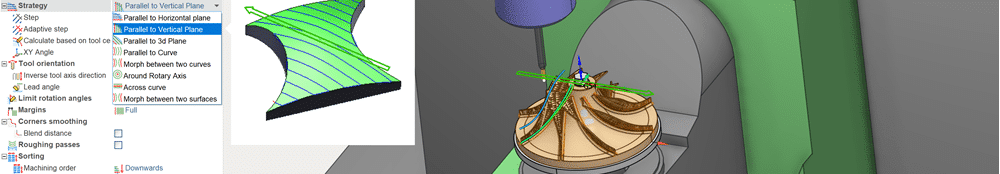

SprutCAM Advanced Features

SprutCAM’ s Multiaxis toolpath contains extensive strategies for controlling toolpaths and tool axes SprutCAM offers the most comprehensive set of 5 axis machining strategies available today, as well as an adequate technology solution that can take on any 5 axis machining

SprutCAM EDM Machining

With SprutCAM's wire EDM machining, SprutCAM EDM can produce curvilinear contours in 2 and 4 dimensions. EDM is an electrical discharge machining process that is primarily used for machining applications involving this process. In this device, a current is transmitted between

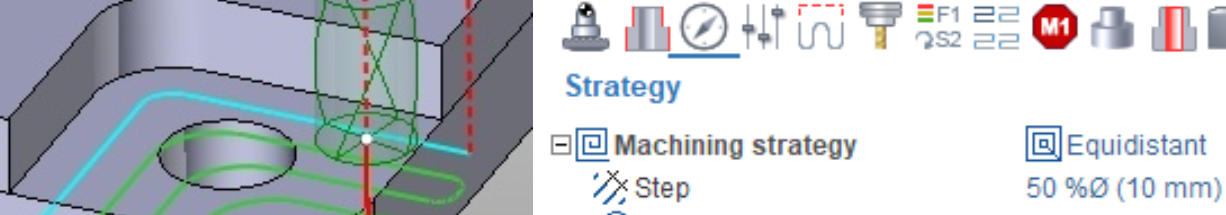

High-performance cutting with SprutCAM

Sprut HPC is a high performance cutting strategy designed for efficient removal of material from both open and closed pockets. The following operations support this strategy. Rough waterline Pocketing Pocketing 2.5D Flat land finishing You can select this strategy from the option

MaxxCAM software simplifies the Nesting

Laser cutting is a widely-used technique for efficiently cutting through industrial-grade materials like Stainless Steel, Mild steel, and aluminum. To ensure optimal utilization of laser cutters, appropriate software is essential. Nesting software plays a crucial role in maximizing the number of