Use CAMWorks 5 Axis Trimming for Clean edges

5 Axis Mill can be used to trim material from parts that have been thermoformed or are composed of composite material.

The majority of plastic thermoformers and composite part makers use 5-axis CNC trimming equipment as this is regarded as the best solution for clean edges and high precision..

As a result of its high precision trimming capabilities, this technology is mainly utilised in aerospace products and medical prosthetics.

CAMWorks is probably one of the most powerful CAM software packages for 5 axis trimming.

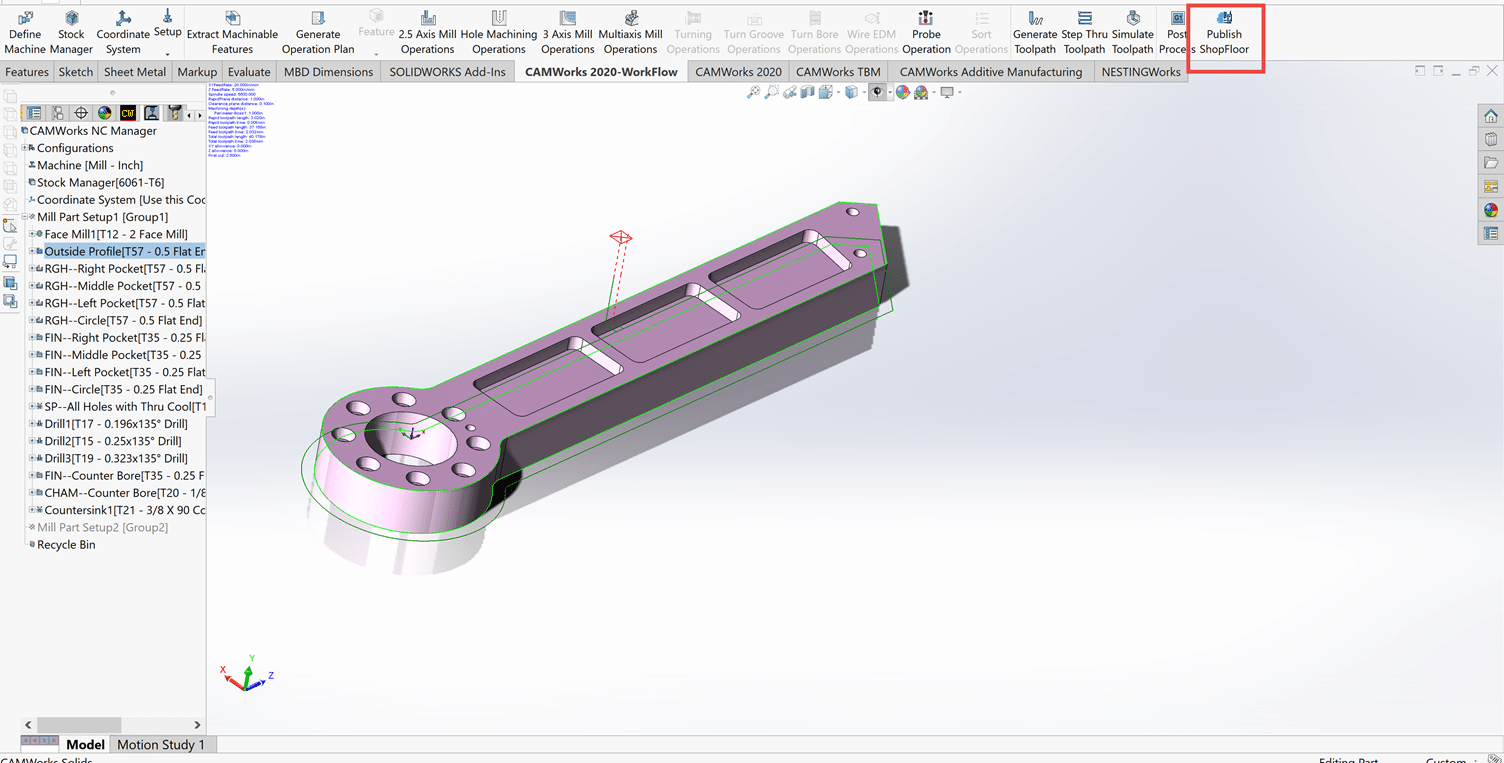

How to program

In CAMWorks, trimming is similar to the usual 5 axis machining process. Only the machining strategy and related operational parameters will differ.

Once the machine, stock and coordinate system are defined, create a new multi-surface feature to the mill part setup.

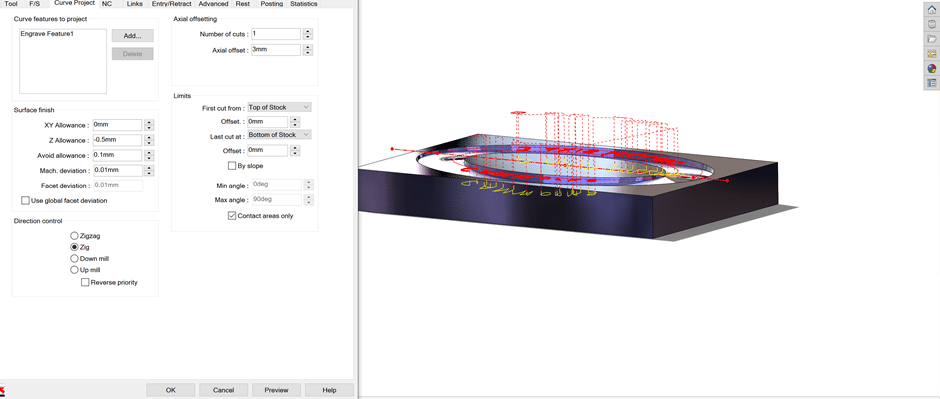

Select the feature type and strategy as faces or surface and 5-axis. Then for the Selected Faces, select the faces around the edges of the part.

Then generate operational plan and swap the tool if needed.

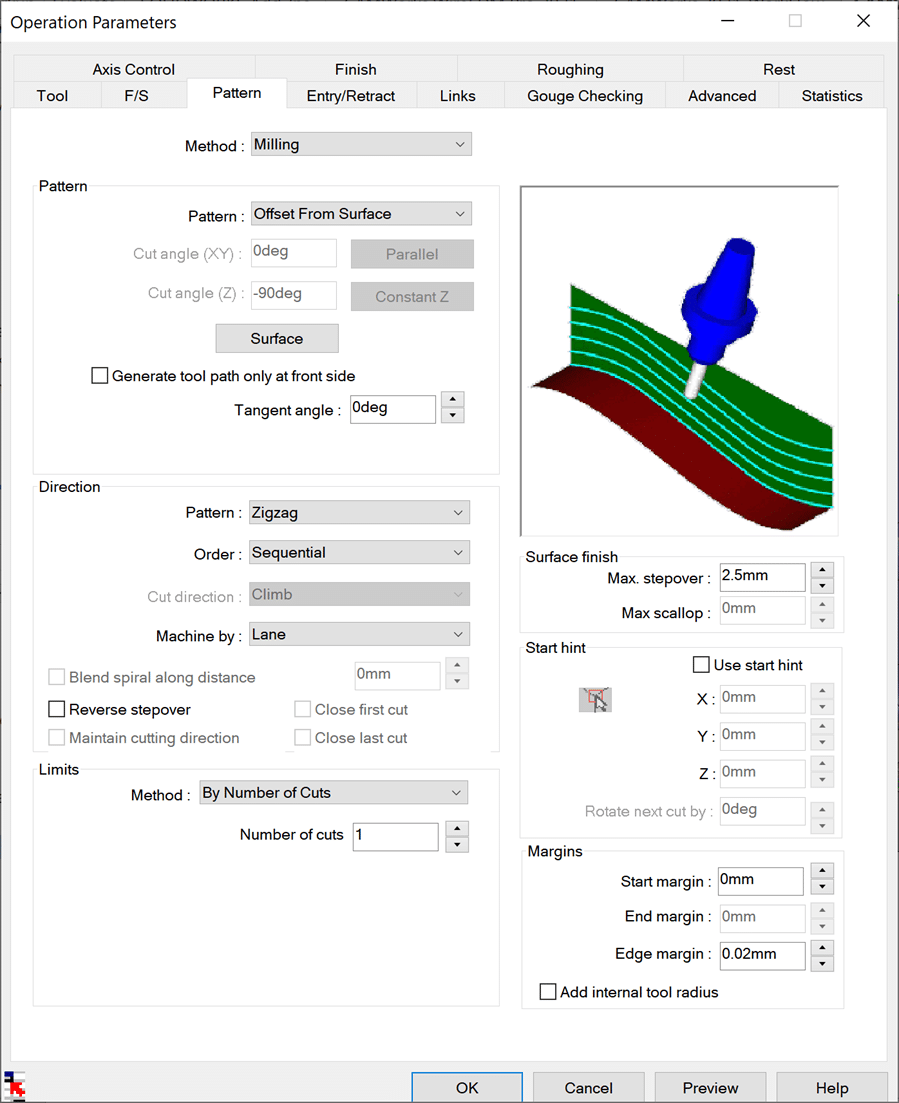

Right-click the Multi-Surface Feature1 and open the edit operation parameters dialogue box. In the pattern tab, select offset from the surface option and select the faces that connect to the Multi-Surface Feature1. Edit the other parameters as per the desired output and click OK.

On the CAMWorks operation tree, right-click on Setup1 and open the setup parameter dialogue box, go to the Fixtures tab and assign the fixture component.

Then run the simulation to verify the toolpaths.

Though CAMWorks is intuitive and straightforward to use, assistance is available should you require it.

For more information on CAMWorks Software and product enquiries, visit us at http://www.nctools.com.au/or call us on +61 3 8618 6884.