SprutCAM – Cost-effective and powerful solution for CNC programming

SprutCAM is a new-generation software program that works directly with the imported CAD data; it automatically calculates and generates an efficient toolpath for machining a model that can be graphically simulated to allow the user to check the machining parameters. After the user accepts the toolpaths, the software will generate NC programs using one of its extensive lists of postprocessor. The system also allows users to develop postprocessor according to their specific requirements.

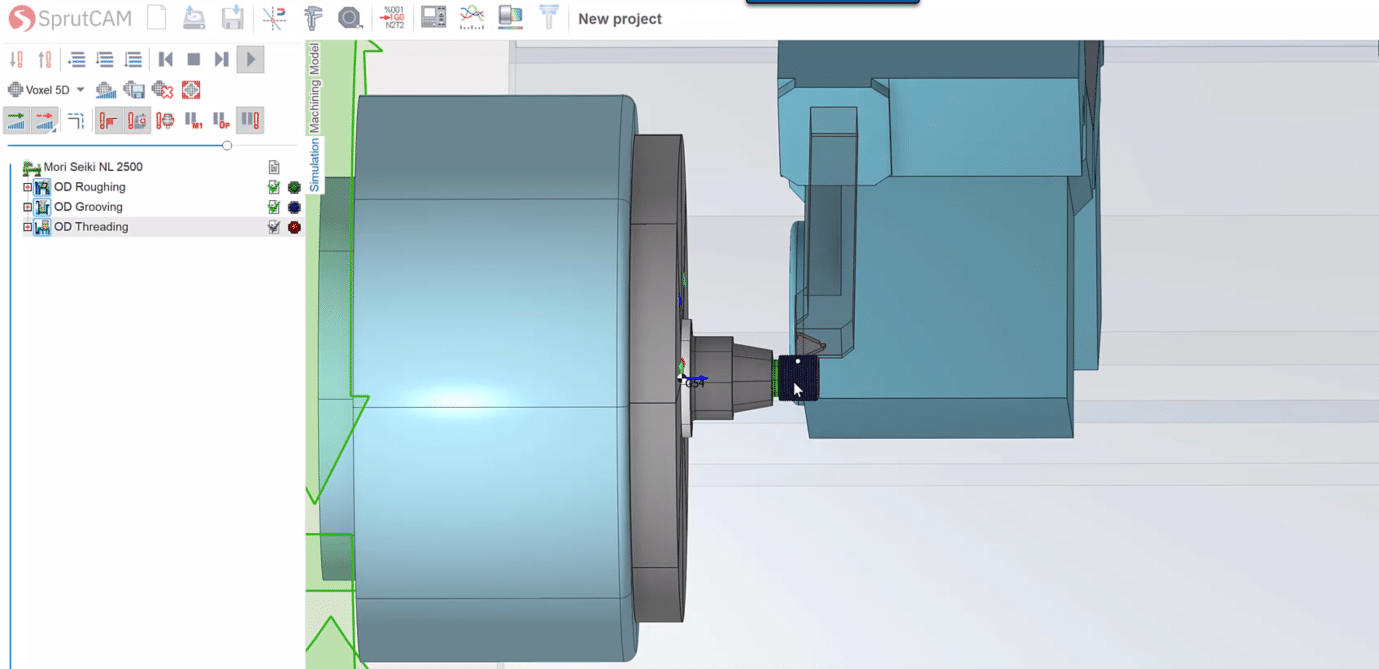

SprutCAM supports 2axis to Multi axis Mill and Turn machines four- or five-axis milling machines and Industrial Robots. More machining methods and strategies are available, and users can create features based on their requirements.

SprutCAM features:

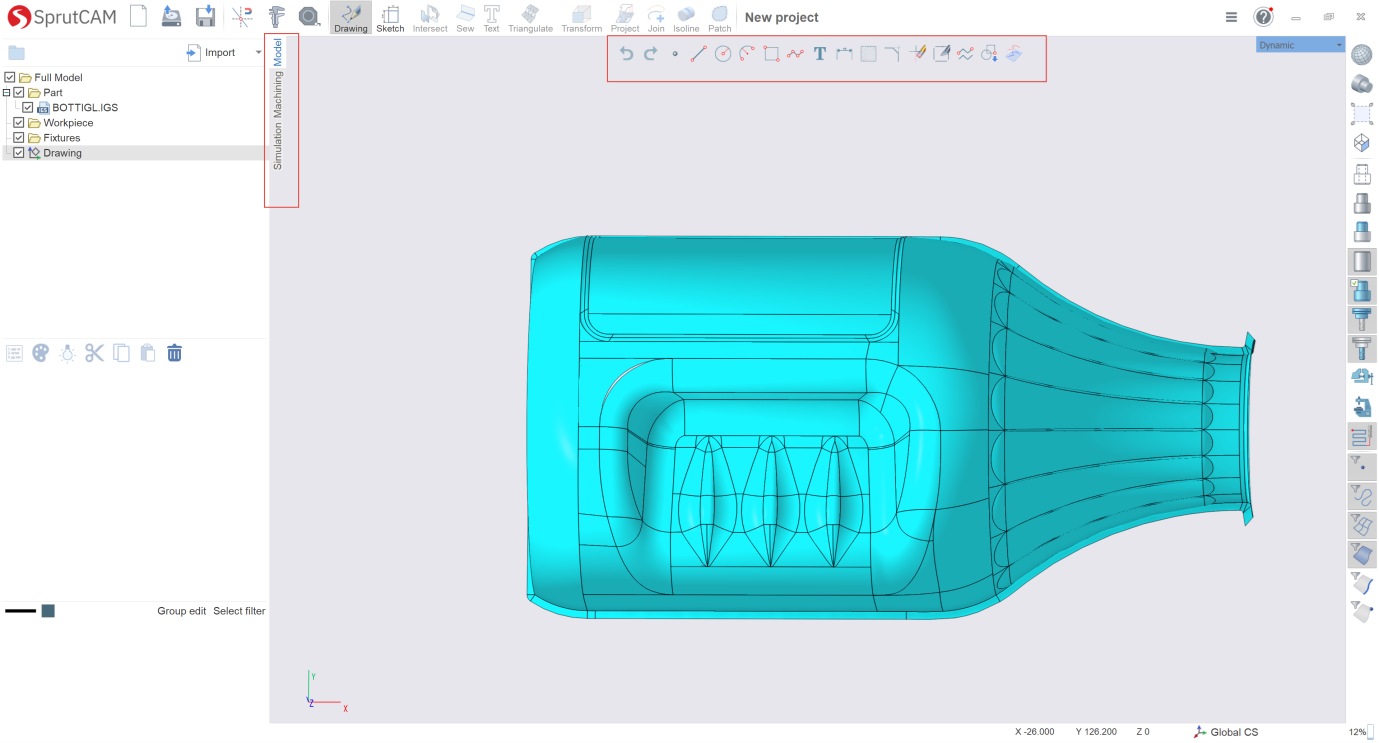

Ease of use: SprutCAM is very easy to use, and it is organised into four main modes, which can be easily selected on the main window by clicking on the relevant tab: 3Dmodel, 2D Geometry, Machining, and Simulation.

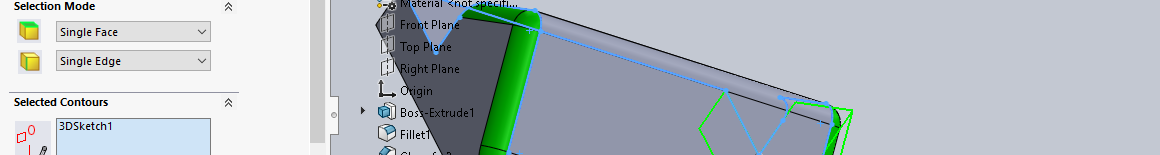

CAD Import Options: In SprutCAM there is the ability to import a geometrical model from any draftsman’s or designer’s systems (CAD/modelling) via data exchange files formatted as: IGES (*.igs, *.iges);STEP (*.step, *.stp);DXF (*.dxf);PostScript (*.ps, *.eps);STL (*.stl);PLY (*.ply);AMF (*.amf);VRML (*.vrl);SOLIDWORKS (*.sldasm, *.sldprt);SOLID EDGE(*.asm, *.par, *.psm, *.pwd);or directly from Rhinoceros (*.3dm);Parasolid (x_t; x_b).

2D drafting: Using the built-in 2D drafting tools, users can create or draft objects in any plane, which can be referenced to the coordinates of the 3D model. In addition, the 3D model can be projected onto a plane. Patterns and text for engraving or pocketing can also be created within the system.

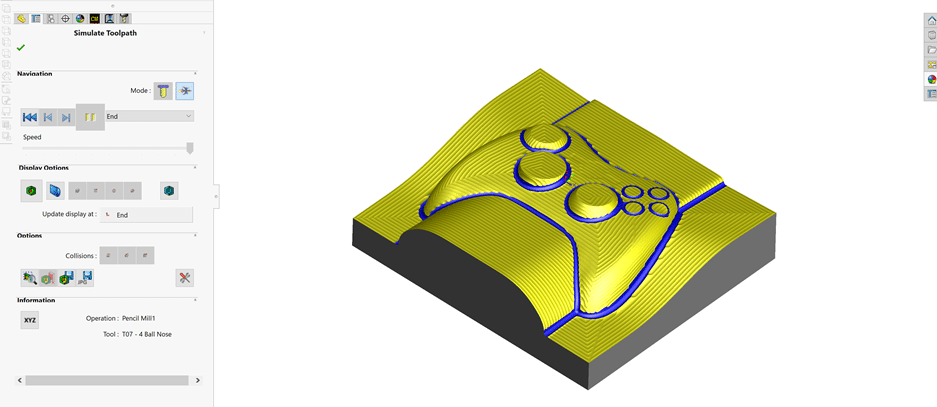

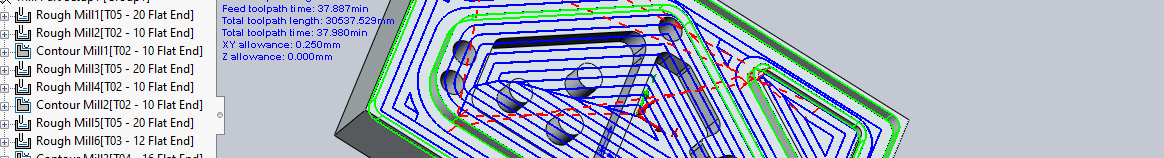

Sophisticated machining cycles: Machining in SprutCAM is easy. In this process, users can choose the required operations from the available list (roughing, finishing, hole-drilling, engraving, etc.). In each operation, the user chooses the parameters that should be applied (waterline, plunge, depth of cut, scallop height, cutting speeds, conventional or climb cutting, etc.). Any of these parameters can be edited and modified without disturbing the whole operation. The resulting machine process is very accurate and efficient within a short time, as all unnecessary tool movements can be eliminated.

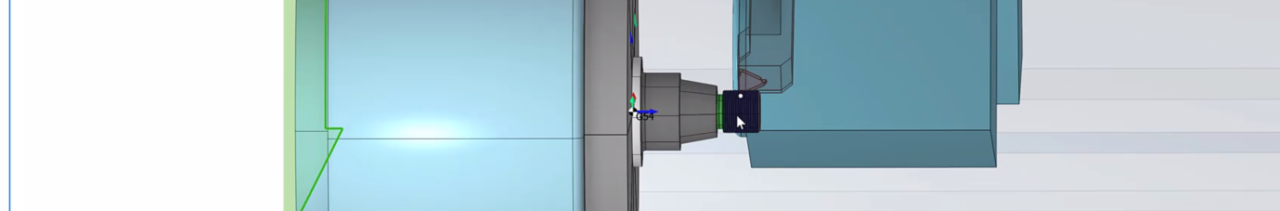

Simulation with collision detection: By using the simulation option, users can see exactly how a part is going to be machined in a step-by-step mode. Users can choose the color of the various tools used and the stock material to better understand the operation. In the simulation tab, there is an option to stop the simulation when any collision or error occurs in the machining process.

Postprocessor: When the machining cycle is accepted, the postprocessor can automatically generate an NC program to import into the CNC machines. It is also possible for the user to generate new postprocessor or modify existing ones by using the inbuilt postprocessor generator.

For more information on SprutCAM Software and product inquiries, visit us at https://nctools.com.au/ or call us on +61 3 8618 6884