Why SOLIDWORKS users will benefit from NestingWorks

In the past, the only way to carry out the process of Saving DXF for SOLIDWORKS users was to save individual parts as DXF, though some of the Free Macros available can make this process a bit easier. Now, however, NestingWorks software which provides for automated nesting for users inside SOLIDWORKS. This works using algorithms that determine the optimal way to layout the required number of parts whilst minimising waste. As well as simply finding efficient ways of laying out cutting patterns,

If your business relies on either outsourcing Laser cutting or Router CNC machining, then NestingWorks software could be a valuable investment.

- Full Associativity with SOLIDWORKS

NestingWorks layouts update with changes in design. The updates are tracked and flagged whenever the component is changed. Also compatible with downstream manufacturing tools.

- SOLIDWORKS Compatible output or Standard DXF output

It provides the nesting output as a new SOLIDWORKS assembly and retains the original part and assembly. The SOLIDWORKS nested assembly can then be used for further processing, such as toolpath and NC Code generation with CAMWorks or any other CAM software if required.

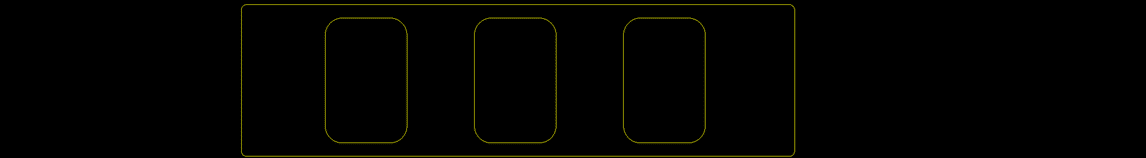

- Part Requirements automatically assigned

Automatically sorts multiple parts, based on material and thickness, within an assembly in a single run. This feature helps users eliminate manual efforts in segregating individual parts with the same material and thickness for a nesting operation.

- Material Optimisation

The advanced true-shape automatic nesting algorithms reduce raw material consumption by providing optimised and compact layouts. Wasting less means you’re getting the most out of the materials you use, and it reduces the amount you dispose of.

- Cost savings.

Wasting less material means paying less of it in the first place. This can mean more money in the bank for your business, providing up to 20% material savings. In particular, if you are outsourcing your laser cutting you know exactly the amount of sheets you need for your parts.

For more information on NestingWorks Software and product enquiries visit us at https://nctools.com.au/ or call us on +61 3 8618 6884