How does a Mill-Turn machine work?

The Mill Turn machine is a hybrid CNC machine. Mill/Turn incorporates the advantages of both turning and milling in one operation.

In order to understand how a Turn Mill machine functions, you must first understand the principles of turning and milling. CNC milling is a machine process used to manufacture custom-designed parts or components by using rotating multi-point cutting tools and computerized controls to remove material from the workpiece. Generally, these systems have three degrees of freedom. They are free to move around the X, Y, and Z axes while the workpiece remains stationary. As a result of this limited dimensional operation, milling is more suitable for prototyping and small runs of production

Turning is a manufacturing process that involves holding bars of material in a three or four jaw chuck and rotating them as tools are fed to the piece to remove material until the desired shape and dimension is achieved. When the CNC turning centre has only one turret, all the work can be performed from one side, but some turning centres have both a main spindle and a sub spindle for even faster operation. This configuration involves machining the workpiece on the main spindle, which is then transported to the sub-spindle to complete the job on the opposite side of the part in a single setup. Due to the speed of CNC turning operations, this is an ideal process for large production runs with short lead times.

Fig 1 Turning

Fig 2 Milling

In summary, Turn Mill is a hybrid CNC machine that combines both milling (tool rotation) and turning (workpiece rotation) capabilities into a fast, powerful, and flexible device that can complete complex operations faster and more accurately than traditional machining methods.

One of the advantages of the mill-turn is that for the right parts, they can be “done in one” with the automatic feed and part catcher, we can run parts in short times without the need for an operator to load and unload the machine. Moreover, in some machines, by running both spindles simultaneously, the cycle time is reduced Furthermore, if you wish to watch an operator struggle, you can set up two jobs on the same machine. As a result, it can be considered two machines in one.

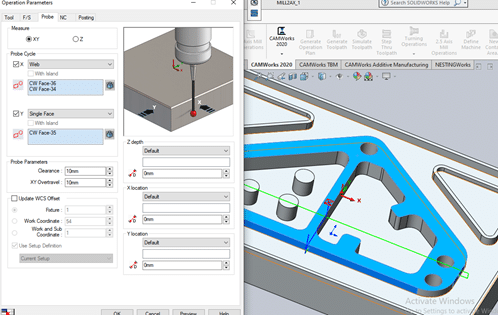

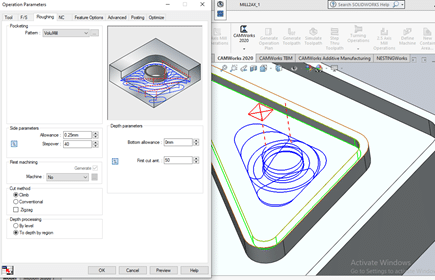

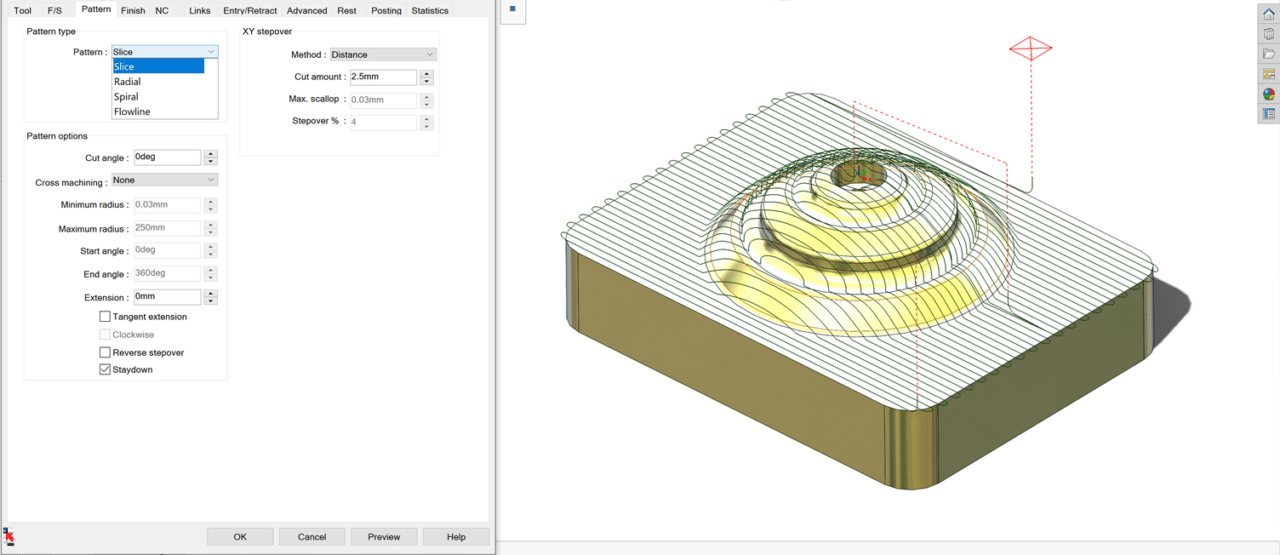

Using SprutCAM software it made easier to define the order of machining operation, tool starting position and modifying stock of the product.

Click here and register to get a free trial version of SprutCAM software.