SprutCAM Australia

CAD/CAM software featuring a streamlined workflow and comprehensive functionality. Compatible with any CNC machine: 3/4 and 5 axis Mill, Lathe, Mill-turn, Swiss, MTM, EDM. Toolpath calculation is performed taking into account full machine kinematics and limitations including collision avoidance and axis limits control.

Streamline your CNC programming workflow with the short learning curve yet powerful CAD/CAM software — SprutCAM

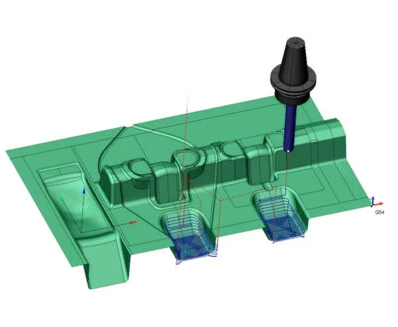

Extensive range of CNC programming solutions

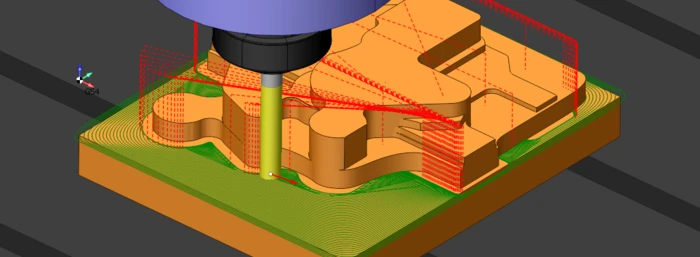

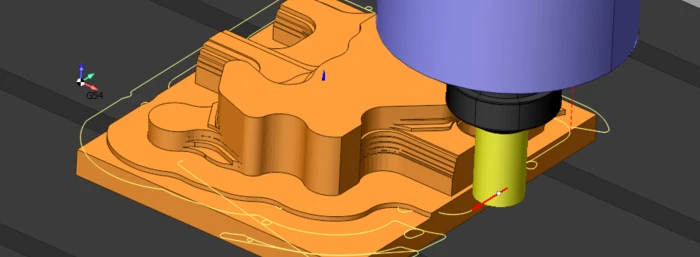

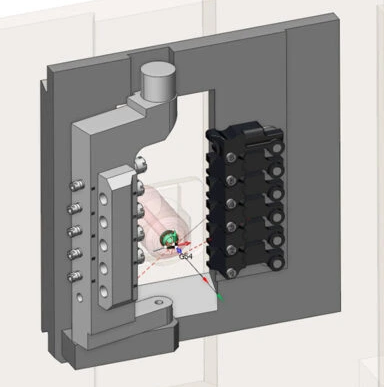

Production of body parts, mold&dies and any other parts on a 3-axis milling machine.

In SprutCAM you get the first toolpath without setting any parameters at all.

After that, you can play with parameters, visually controlling the result.

Remove material quickly

The new “Adaptive” strategy for high-speed machining. Used for fast material removal. Rapid calculation and kinder on the tool.

Remove material quickly in CAM system

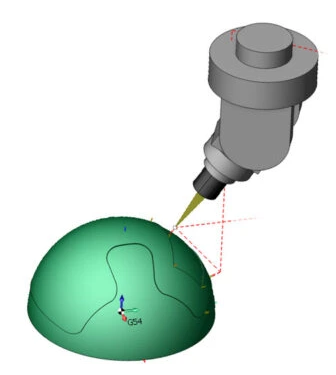

Get the required surface quality

Comprehensive finishing toolpath strategies including scallop and morph will help you to obtain the desired surface finish.

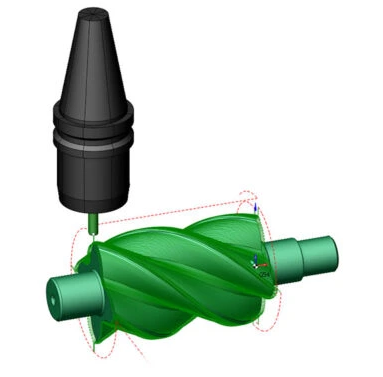

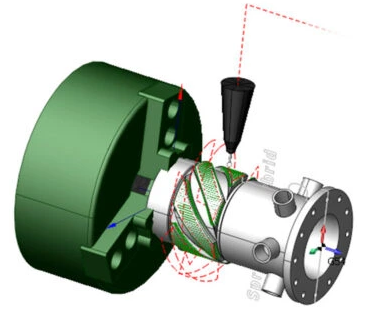

Milling with 4th axis. Productions of screws, blades, gear wheels, balusters

All 3-axis toolpath strategies are available for 4 axis index machining.

SprutCAM has roughing toolpath for quick material removing and finishing toolpaths for the required surface quality for the 4-axis continuous machining.

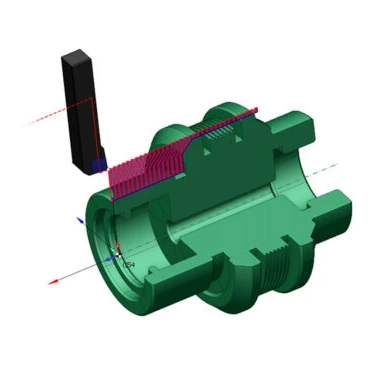

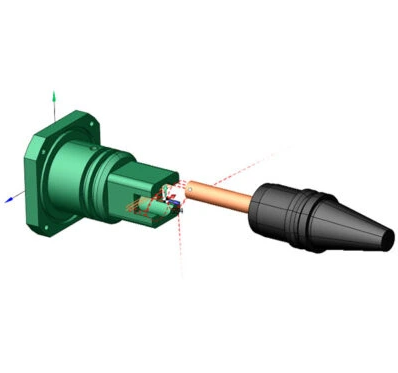

SprutCAM for lathe machines: turning and boring of cylindrical, conical and shaped surfaces, threading, trimming, facing, drilling and reaming holes.

All types of turning operations

- Facing, ID and OD roughing, finishing, threading, grooving, face grooving, lathe hole machining, part-off.

- Lathe canned cycles

- According to the user’s preference, SprutCAM can optionally output G-code using lathe cycles.

SprutCAM calculates lathe toolpaths and all other machining processes using the native kinematics of the CNC machine.

What does this mean to the user?

This means that collisions between machine axes as well as the workpiece are handled automatically during toolpath calculation.

You do not need to postprocess the NC code to simulate the real-world result. All machine movements are visible immediately after the toolpath calculation.

CNC programming becomes visual, workflow is streamlined.

Further, thanks to this feature the user can save even more machine time by fine tuning of the machine. For example reducing cycle time by optimizing the tools location in the turret.

SprutCAM for mill-turn is a complete multi-tasking CNC programming software for all-in-one machining in a single setup

- Streamline CNC programming workflow with SprutCAM

SprutCAM calculates lathe toolpaths using the native kinematics of the CNC machine.

What does this mean to the user?

This means that collisions between machine axes as well as the workpiece are handled automatically during toolpath calculation.

You do not need to postprocess the NC code to simulate the real-world result. All machine movements are visible immediately after the toolpath calculation.

CNC programming becomes visual, the workflow is streamlined.

SprutCAM can perform turning and milling toolpaths in any order. The workpiece for each subsequent operation is the result of all the previous ones. You can see the current state of the workpiece at every step.

SprutCAM can perform turning and milling toolpaths in any order. The workpiece for each subsequent operation is the result of all the previous ones. You can see the current state of the workpiece at every step.

In the screenshot; green color is the part itself and orange is the result of all previous operations. This becomes the workpiece for the next operation.

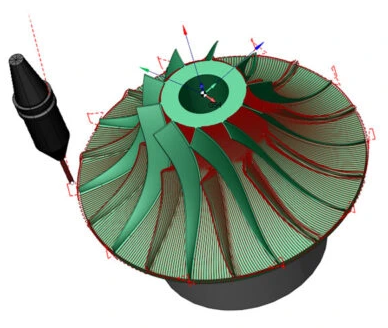

Index (3+2) and simultaneous 5-axis milling. For turbine wheels, blades, ports milling.

- Rest material handling

SprutCAM always keeps the workpiece updated live within the operations sequence to optimize the toolpath and avoid air-cutting.

Every subsequent operation detects the workpiece in the state it was left by previous operation.

Thus the machine time is kept optimized.

On the screenshot, the green color is the part itself and orange is the current state of the workpiece.

- Machine kinematics consideration

SprutCAM takes into account the machine kinematics with all its limitations when the toolpath is calculated.

The simulation automatically commences in the background immediately after the toolpath is

calculated. The user can avoid any collisions that may occur without having to switch to Simulation mode.

Thus the CNC programming workflow is very streamlined and takes much less time; especially for multi-axis programming.

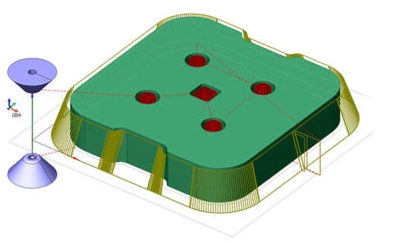

High speed and adaptive toolpaths for quick material removal.

Tool life considered.

High speed machining in SprutCAM

Adaptive

Small step, large cutting depth

High speed cutting (HPC)

Large step, small cutting depth

Swiss-type machines and MTM (multi-channel machining) with synchronization

CNC programming of cutting, trimming, 6D knife cutting. Mill, laser, water, plasma, knife

- 5D cutting highlights

5-axis cutting machines programming features

Get toolpath instantly

To get the toolpath:

- Specify the edge on the model;

- SprutCAM will offer to choose one of the adjoining surfaces to control the tool axis;

- Select the direction of the tool axis relative to the selected surface: tool tip or flank;

- Press Run.

SprutCAM works with both the solid model and the mesh model.

Tool axis control at every toolpath point: lead and lean angles

After calculating the toolpath, you can edit the tool vector at each point. It is possible to set the lean and lead angles at any point of the toolpath.

Lean and lead angles can be set manually or automatically using the toolpath optimization map.

It is useful to avoid collisions between machine and parts, and singularities.

Interactive toolpath editing after calculation

Often, the actual part geometry does not match the CAD model.

Therefore, in SprutCAM, the toolpath is converted into a spline and can be edited directly in the interface.

- 6D cutting highlights

Additional axis support

SprutCAM supports additional axes.

For example, a 6th rotary axis located on the machine table.6D knife cutting

SprutCAM has a special solution for knife cutting for the knife safety and blade direction control.

What can be configured:- toolpath curvature limit when knife turning in the material;

- the knife can be double-sided: you can cut using either edge of the knife;

- knife retraction and rotation in the air at sharp toolpath corners.

Programming of cladding and hybrid technology on 5-axis mill and mill-turn machines

SprutCAM supports these types of additive technologies

Metal cladding

Plastic 3D printing

Concrete 3D printing

Stem cells 3D printing

2 – 4 axis wire EDM machining in SprutCAM

2&3-axis wire EDM

«Wire EDM 2D Contouring» operation is used for the creation of a wire path along a 2D contour (2-axis machining) as well as for the movement along a 2D contour with a tilted wire (conic or 3-axis machining).

Therefore, the resulting wire path is based on one contour in contrast to 4-axis machining, where the contours described by the wire in the lower and the upper planes are to be specified separately.

«4D electrical discharge machining of the contour» operation is used for the generation of a wire path along two 2D contours simultaneously. One of these contours defines the movement of the lower sliding guide, and the second contour specifies the movement of the upper sliding guide.

Therefore, in this operation in contrast to «2D machining», the upper and lower ends of the wire can describe a completely different path.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.