CAD Automation – Increase productivity

CAD Automation - Manufacturing Companies always target to meet high production with the best quality. Design is one of the main processes in manufacturing takes more time and delays in delivering the product. To overcome this challenge, manufacturing companies started

DXF for laser cutting – How to be smarter and more productive

Many companies spend hours preparing the DXF for laser cutting files their customers send them. These DXF files typically consist of many layers that contain information for manufacturing. Nestled in them is a flat pattern layer for laser cutting. This was

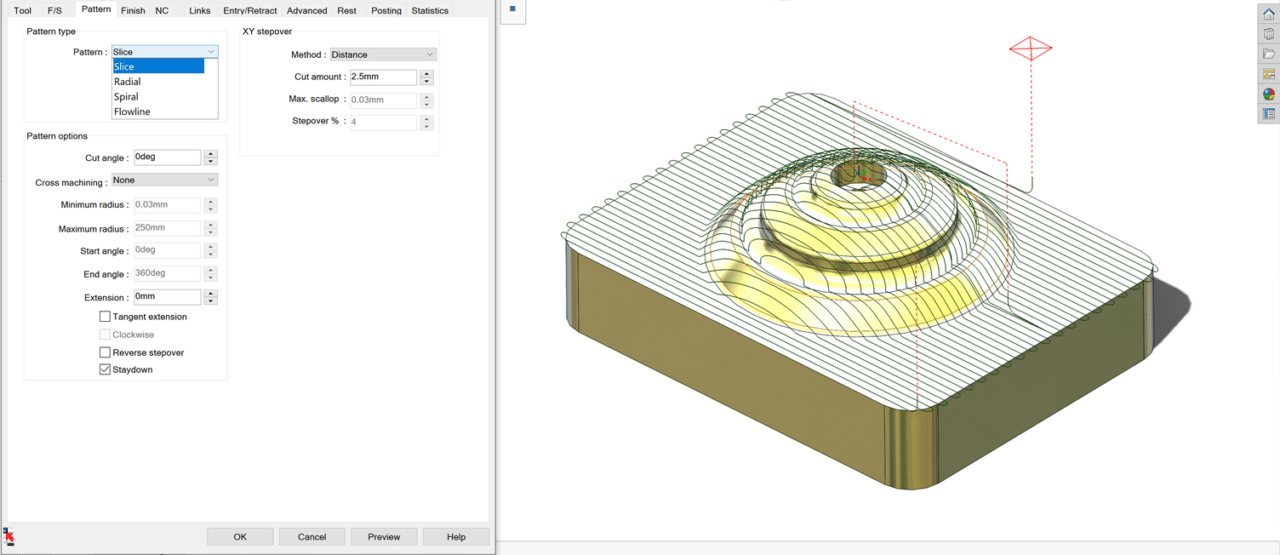

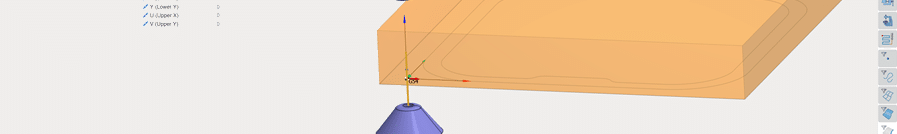

SprutCAM Spiral Face Milling

SprutCAM adaptive face milling minimizes the cycle time for facing operations: In contrast to regular face milling, SprutCAM utilizes adaptive face milling to enhance the machining strategy. The focus is on reducing cycle time through tool paths. The tool path

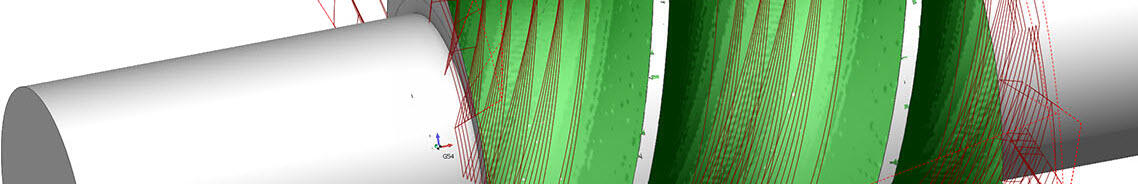

How does a Mill-Turn machine work?

The Mill Turn machine is a hybrid CNC machine. Mill/Turn incorporates the advantages of both turning and milling in one operation. In order to understand how a Turn Mill machine functions, you must first understand the principles of turning and milling.

SprutCAM EDM Machining

With SprutCAM's wire EDM machining, SprutCAM EDM can produce curvilinear contours in 2 and 4 dimensions. EDM is an electrical discharge machining process that is primarily used for machining applications involving this process. In this device, a current is transmitted between

MaxxCAM software simplifies the Nesting

Laser cutting is a widely-used technique for efficiently cutting through industrial-grade materials like Stainless Steel, Mild steel, and aluminum. To ensure optimal utilization of laser cutters, appropriate software is essential. Nesting software plays a crucial role in maximizing the number of

Tolerance Based Machining (TBM) with CAMWorks

In addition to CAMWorks AFR for identifying manufacturing features and automating the creation of tool paths. In addition, CAMWorks introduced features for recognizing dimensions, tolerances, and surface finish annotations associated with models. Camworks' tolerance based machining can recognize Solidworks dimensions,

Introducing CAMWorks 2022

CAMWorks 2022 delivers the performance improvements you need so you can get your work done faster! CAMWorks constantly updates its software to satisfy the requirements of the manufacturing industry, as well as offering features to assist manufacturers through its software. A

How do you determine the laser cutting cost?

Laser cutting is a technology that uses a high-powered laser beam to cut materials with a high degree of precision and accuracy. Due to its ability to produce high-quality cuts quickly and efficiently, it has become a popular choice for

Frequently asked questions and answers about laser cutting quote software

How Does a Fibre Laser Work? Optical fibres are used as the active gain medium in fibre lasers, which are solid-state lasers. The pump laser diodes emit raw light, which is absorbed by fibres composed of silicate or phosphate glass in