Automate your manufacturing process with Feature-based machining (FBM)

Automate your manufacturing process A key function of manufacturing process planning is the planning of machining sequences. The term Manufacturing Feature refers to a component of a part that can be manufactured using a standard machining process. Holes, pockets, slots, grooves,

5 Reasons why Smart Cut Quote Software can speed up your laser Quoting process

The laser cutting quoting software saves you time In the laser cutting business, determining the price of your cutting Service can be one of the most challenging tasks. Developing a price for your product/service depends on so many variables that it

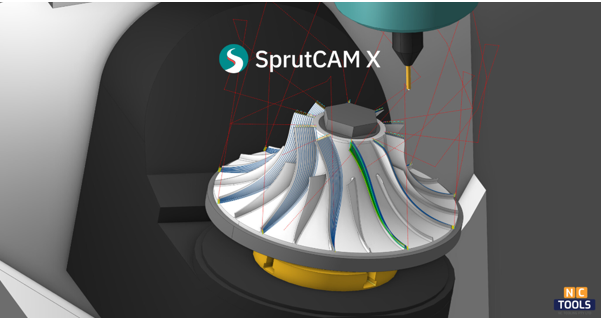

SprutCAM 5 axis machining and how it can benefit your business

5-axis refers to a machine's ability to move a tool in five directions at once. The main benefit of 5-axis machining is that it is able to produce complex shapes using a single setup. SprutCAM generates toolpaths for 5-axis milling

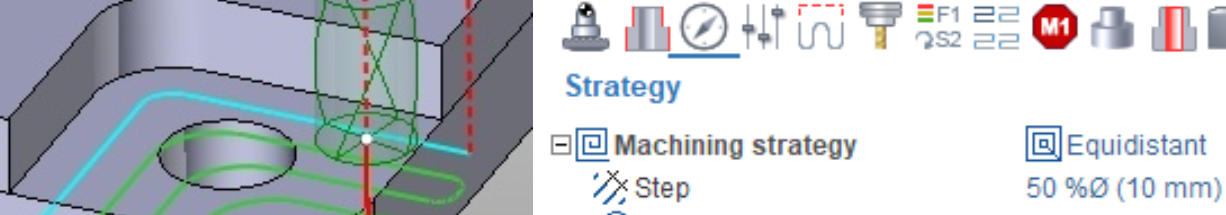

SprutCAM Spiral Face Milling

SprutCAM adaptive face milling minimizes the cycle time for facing operations: In contrast to regular face milling, SprutCAM utilizes adaptive face milling to enhance the machining strategy. The focus is on reducing cycle time through tool paths. The tool path

MaxxCAM software simplifies the Nesting

Laser cutting is a widely-used technique for efficiently cutting through industrial-grade materials like Stainless Steel, Mild steel, and aluminum. To ensure optimal utilization of laser cutters, appropriate software is essential. Nesting software plays a crucial role in maximizing the number of

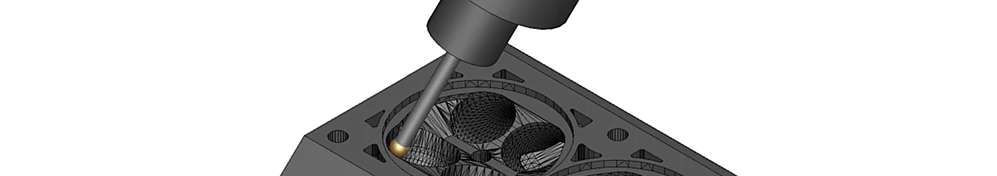

High-performance cutting with SprutCAM

Sprut HPC is a high performance cutting strategy designed for efficient removal of material from both open and closed pockets. The following operations support this strategy. Rough waterline Pocketing Pocketing 2.5D Flat land finishing You can select this strategy from the option

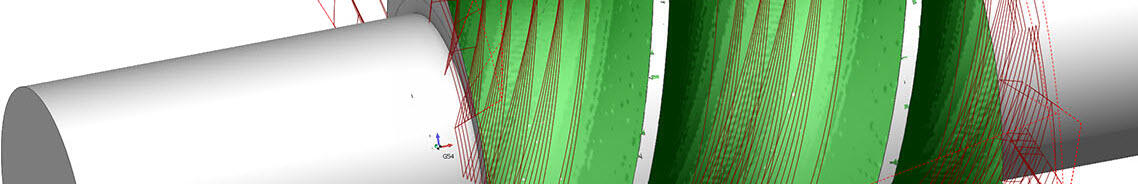

Multi Axis operations with CAMWorks – Port Machining

Port Machining is a common strategy with 5 axis machining to machine the inside of an intake or exhaust channels and other ports. In this blog, we will see the procedure to set this up. This can be done quickly

How to choose the right CNC software for your manufacturing needs

The CNC software used within the manufacturing industry is a computer-aided manufacturing (CAM) program. This system provides data that is used to control CNC machines and other production equipment. As a result of CNC software, technicians are able to perform

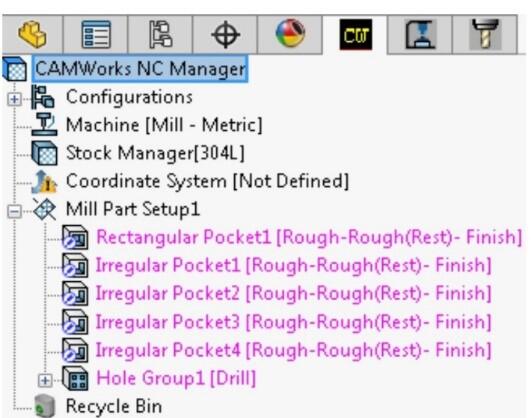

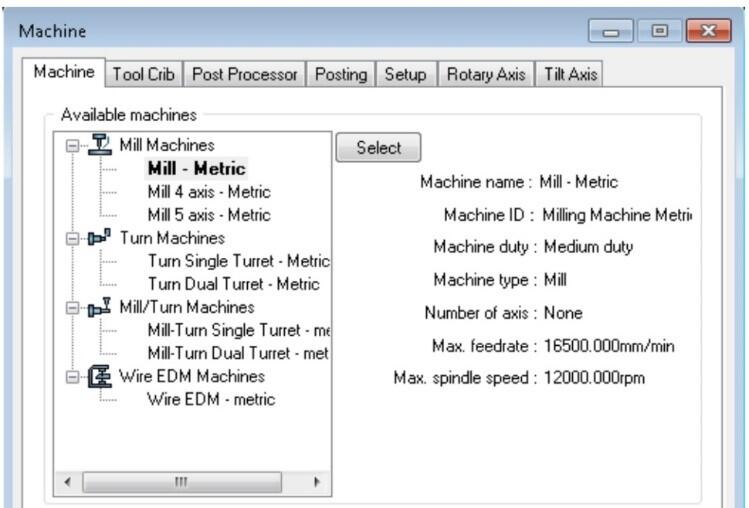

How to generate G-code using CAMWorks/Solidworks CAM inside SolidWorks, follow these steps

Design your part: Make a 3D model of your part in SolidWorks. Be sure all dimensions and features are accurate, as well as that it is properly defined. Set up machining operations: Open the CAMWorks add-in in SolidWorks. Go to the CAMWorks tab

HOW TO WIN MORE LASER-CUTTING JOBS

There is no doubt that the more quotes you send, the more revenue you will generate: It is important to streamline the quoting process in order to increase business capacity. We've noticed, based on our decades of experience in the metal fabrication