SprutCAM Spiral Face Milling

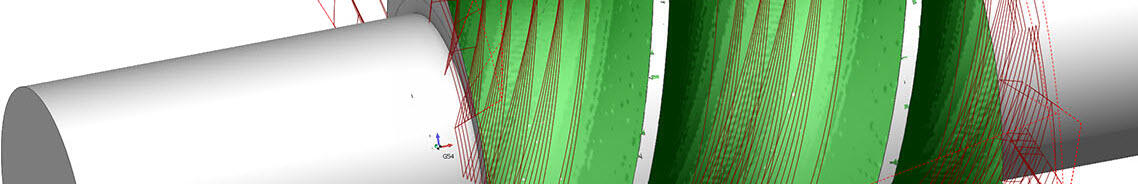

SprutCAM adaptive face milling minimizes the cycle time for facing operations: In contrast to regular face milling, SprutCAM utilizes adaptive face milling to enhance the machining strategy. The focus is on reducing cycle time through tool paths. The tool path for regular face milling moves in a zigzag pattern, meaning the operation takes longer to complete. As for adaptive or spiral face milling, the tool path moves in a circular motion over the material. Stocks will be continuously engaged in this strategy. Contrary to the regular zigzag pattern, the tool will move back and forth during machining and will not have continuous engagement throughout. In SputCAM, add the raw material and mill part setups, select the machine, change the toolpath movement strategy to spiral from the strategy dropdown list box, and confirm the changes. To verify the cycle time, select simulation. If the machining process is designed to remove as much material as possible during its initial stages, this method will be advantageous. This toolpath is useful when using smaller endmills to face and to ensure consistent engagement. A tool path motion is associated with a time-consuming process. This is important to avoid movement of the tool cutting in air and the tool engaging the material in an undesirable angle, which will cause tool wear and reduce tool life.

For more information on SprutCAM Software and product inquiries, visit us at https://nctools.com.au/ or call us on +61 3 8618 6884