SprutCAM EDM Machining

With SprutCAM’s wire EDM machining, SprutCAM EDM can produce curvilinear contours in 2 and 4 dimensions.

EDM is an electrical discharge machining process that is primarily used for machining applications involving this process. In this device, a current is transmitted between charged wires and the workpiece at a frequency ranging between 50 Hz and kilohertz. In this process, the wire and the workpiece are separated by a dielectric liquid.

When machining with traditional methods is impossible or uneconomic due to wastage or difficult (hardened) materials to machine, wire EDM is used.

A CNC wire EDM machine is used to cut sheet metals using electro-erosion. The machines can be equipped with 2 or 4 axes that can cut curvilinear contours with either vertical or tapered sides.

SprutCAM provides NC-programs for both 2 and 4 axis wire EDM:

- Wire EDM for 2D contouring

- Wire EDM Contouring 4D

For creating wire paths, contouring operations are performed using a two-dimensional contour for a two-axis contour, or simultaneously along two contours: upper and lower, for a four-axis contour. Multiple contours can be processed in one operation. From the job assignment, the user can select the contour operation required. For each contour, one must specify the start and stop points for machining, the load point and wear point of the part, the draft angle, etc.

Additionally, SprutCAM Wire EDM offers the option of utilizing additional approach and retraction moves from the beginning to the end of each contour, thereby ensuring a complete and accurate machining process. The Lead In/Lead Out parameters are defined in the operation parameters window.

In order to achieve a good surface finish, SprutCAM features a variety of pass methods, such as rough finish, bridges, cutoff, etc. These strategies can be enabled through the operation parameters. The following additional features will contribute to the achievement of good surface finishes: optimised path direct, etc.

Wire EDM 2d Contouring

The wire EDM 2D Contouring operation is designed to create wire paths along flat contours as well as along flat contours with wire slope angles (tapers) or 3D contours. Wire paths are generated based on contours in a single plane

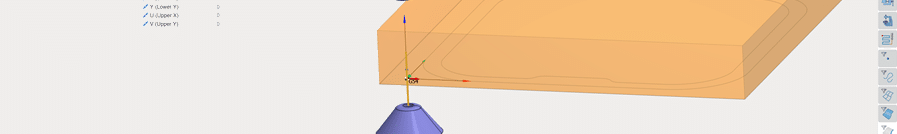

Wire EDM 4d Contouring

Using the Wire EDM 4d Contouring operation, wire paths can be generated along two flat contours simultaneously. One of these contours is responsible for moving the lower guide of the wire EDM machine, or more specifically, it moves the working XY contour plane. With the second contour, the upper guide of the wire EDM machine is moved – the leading UV contour. As a result, the upper and lower wire ends can move in different directions while in operation.

For more information on SprutCAM Software and product inquiries, visit us at https://nctools.com.au/ or call us on +61 3 8618 6884