Automate your manufacturing process with Feature-based machining (FBM)

Automate your manufacturing process

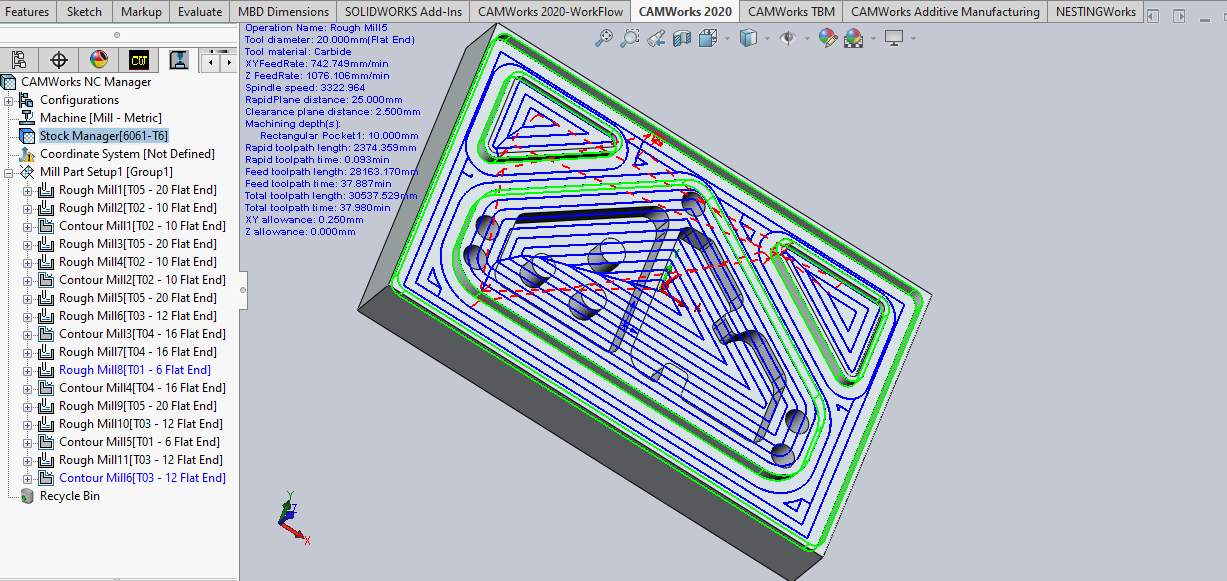

A key function of manufacturing process planning is the planning of machining sequences. The term Manufacturing Feature refers to a component of a part that can be manufactured using a standard machining process. Holes, pockets, slots, grooves, and chamfers are examples of features.

FBM is a CAM approach based on the recognition of features and the automatic or automated generation of machining processes using the information extracted from the recognized features and a Machining Knowledge Base.

FBM Mill Group

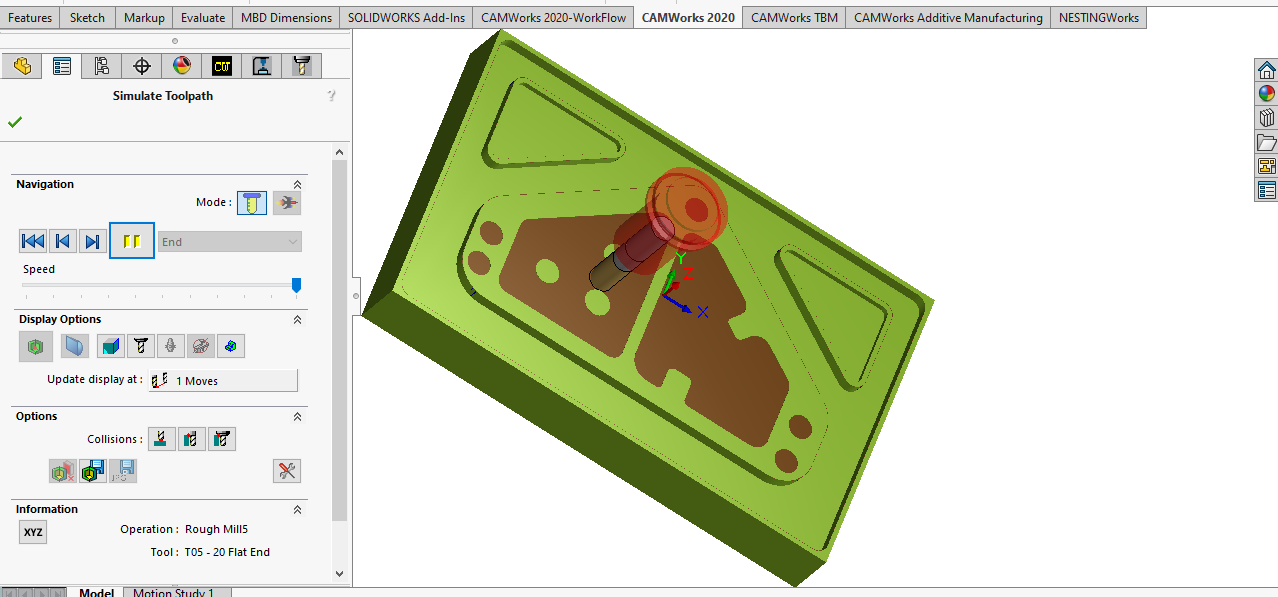

With the FBM Mill Group in SprutCAM X, you can perform Feature Based Machining.

In SprutCAM X, all known features of a part are recognized automatically when you create a new FBM Mill Group operation. You can then select predefined or stored machining procedures from the FBM Procedure Library for the features, and SprutCAM X will automatically generate the operations necessary to machine these features and sort them according to the current rules (sorting operations is a strategy to minimize tool changes).

FBM Machining

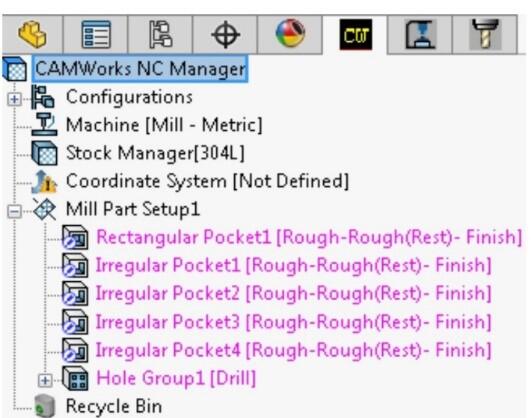

In the FBM process, a machining sequence is defined for a particular feature class. FBM procedures can be classified into two types.

• Atomic procedures

• Complete procedures

Atomic machining is only a small part of the machining process. It usually consists of just one operation. A few examples of atomic procedures are spot drilling, rough drilling, chamfer sinking, and chamfer contouring.

A Complete procedure consists of all the operations needed to completely machine a feature.

In the UI, only complete procedures are suggested when you select a procedure for a feature. Adding operations to a selected procedure will only suggest atomic procedures.

There are four parts to a FMB procedure.

● Metadata about the procedure, including its type (atomic or complete), caption, icon, and date of last modification.

● The Feature Constraints.

● The Tool Query List

● The Operation List

Feature Constraints

Constraints define what type of feature is to be implemented and what parameters should be met. There are several types of features, including Hole, Stepped Hole, and Hole Groove.

There are a number of parameters associated with each type of feature.

Tool query list

The Tool Query List contains entries that specify the rules for selecting tools from the Tool Library for machining operations. The desired tool type and constraints for the tool parameters are specified for each tool query.

Operation list

Operation lists are lists of machining operations that can be performed with a specific feature.

For more information about SprutCAM Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884