CAMWorks® New ShopFloor! Program Smarter – Machine Faster

A Digital Transformation is underway..

And it’s not just Paperless but Digital – Drawings and other documents can be converted to PDF’s (for example) to create “Paperless” environments… but unlike a static PDF. digital information can be analysed and leveraged by downstream applications like CAM, inspection, suppliers, and service.

A major part of this transformation is The Digital Twin. The digital twin is a virtual representation of a part or assembly, for example, a SOLIDWORKS® model that also includes manufacturing information.

The IIoT is the industrial framework for the transformation and it combines multiple electronic devices, machines, systems, applications, and employees into a network, connected by the internet, and/or cloud.

Augmented reality or the combining of virtual and real worlds along with artificial intelligence are rapidly developing technologies in the digital transformation. We might think this is futuristic… but Alexa and Siri are examples of AI already in use. And you can expect to see AR and AI technologies being used in the manufacturing process much more, going forward.

So why is this important? Take a look at this fact… since the year 2000, 52% of the Fortune 500 companies in the USA have gone bankrupt, been acquired, or ceased to exist in large part due to the digital disruption of traditional industry models.

It’s time to bring the machine shop into the 21st century!

So today we’re announcing! The all-new CAMWorks ShopFloor! This exciting new product will empower the shop floor with a new set of state-of-the-art tools to prove-out CNC programs and increase efficiency.

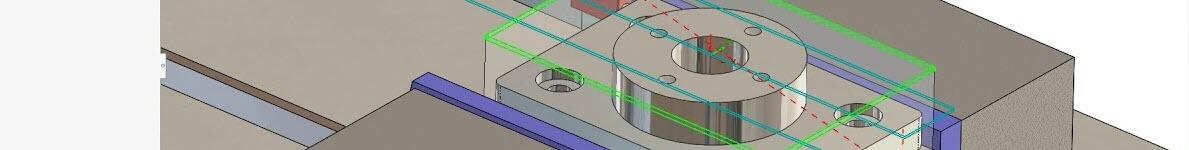

CAMWorks ShopFloor will provide the CNC machinist with new tools, including the ability to digitally view and measure the part model and assembly setup for the CNC program

CAMWorks data including the Operations and Tools tree used to create the CNC program will now be available to the machinist at the CNC machine.

Setup information including 3D Tools, setup sheets, and tool lists will be at their fingertips and digitally displayed.

A state-of-the-art CNC editor is included for the machinist to review and back-plot the G-code, make any final changes to the program, and send it to the CNC machine.

The user will also have the ability to perform Step-through Simulation for each operation or for the entire program.

And Toolpath Simulation with material removal will also be available… to help the machinist see exactly what will happen on the machine, before hitting the cycle-start button.

For more information on CAMWorks Software and product enquiries visit us at https://nctools.com.au/ or call us on +61 3 8618 6884