Laser Cutting Estimation Software -What Factors Are Typically Taken Into Account When Using?

For accurate cost estimates, laser cutting estimation software typically takes several factors into account. A few of these factors are:

1. Laser cutting estimation software takes into account the cost of the material to be cut. Depending on the unit of measurement, different materials have varying costs per square inch or m2. In order to calculate the amount and type of material required, the software considers thickness, type, and quantity.

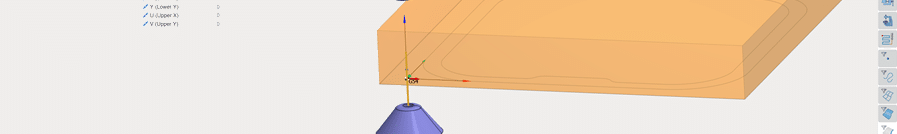

2. Laser Cutting Speed: The software takes the laser cutting speed into account. Consequently, this speed affects the time it takes to complete the cutting process, as well as the overall cost. Estimation is based on the speed of the machine calculated by the software.

3. Laser cutting estimation software takes into account the efficiency of the laser cutting machine. Machine productivity is affected by factors such as the power output, maintenance level, and technology used. This information is incorporated into the software in order to provide accurate estimates.

4. There are various tools and accessories required to perform laser cutting, such as nozzles, lenses, and assist gases. During the estimation process, the software considers the tooling requirements specific to the project and includes the associated costs.

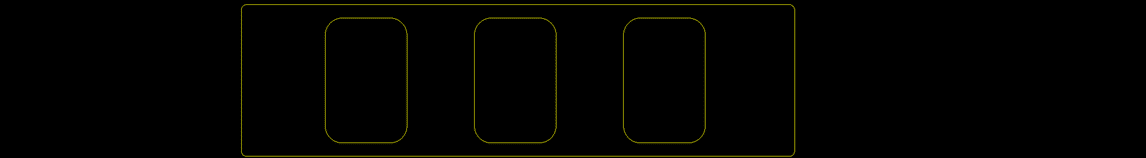

5. Another crucial factor is the complexity of the cutting job. The laser cutting estimation software takes into account factors such as the complexity of the design, the number of cuts required, and any additional processes (such as engraving or etching). A complex job may require more time and resources, which may increase the estimated cost.

6. As a result of the cutting path and spacing between the parts, some material is inevitable to be wasted during the laser cutting process. In addition to considering this waste factor, the software also calculates the amount of additional material that will be required in order to compensate for the waste.

7. A laser cutting estimation software program may also take into account the operator’s wages or the overhead costs associated with operating the laser cutting facility. As a result, this factor can vary based on the region, labor rates, and the type of business.

By taking into account these factors and applying advanced algorithms and calculations, laser cutting estimation software provides accurate cost estimates for laser-cutting projects. As a result of these estimates, businesses are able to make informed decisions regarding pricing, project feasibility, and resource allocation, contributing to improved efficiency and profitability.

For more information about SmartQuote Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884