- June 9, 2023

- Posted by: admin

- Categories: General, Software, SprutCAM

In additive manufacturing, an object is created by layering multiple materials together. Subtractive manufacturing, on the other hand, involves removing material from the workpiece to create an object. The benefits of additive manufacturing include reducing waste and producing parts more quickly and at a lower cost than subtractive methods.

Cladding:

The process of cladding is a form of additive manufacturing that involves melting an additional layer of metal or alloy on the surface of the workpiece.

The cladding has the following characteristics:

- Minimum penetration into the base metal

- Minimum mixing of the added layer with the base metal

- A minimum of residual stresses and deformations within the action zone

Additive operations:

Area cladding:

An area cladding operation consists of adding a layer of material around a local piece of a part that may have curves. In addition to restoring the geometric dimensions of costly parts and tools, it can also repair blades, dies, molds, gears, shafts, etc.

Curve cladding:

Additive operations that create toolpaths with curves are defined in job assignments from top to bottom. These operations are useful for thin-walled models. Curves may be placed on a plane, cylinder, or body of revolution. When the “Project toolpath onto the part” option is enabled, cladding can be applied to any surface, regardless of the shape. Cladding can be generated layer by layer, similar to toolpath or helix spiral.

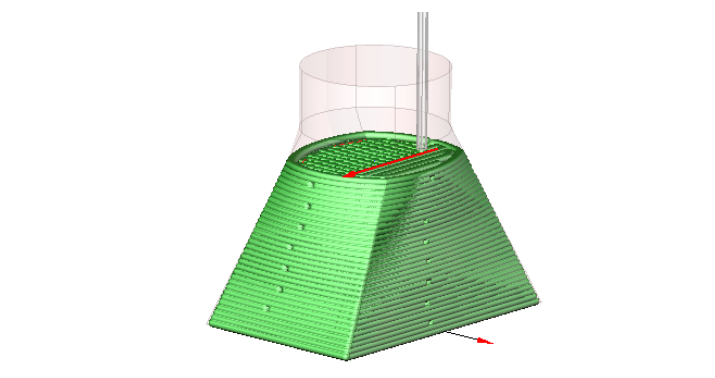

Cladding 3D:

An additive operation with a 3D model as input. This operation is similar to roughing waterlines, except that it works from the bottom to the top. In this program, the source model is intersected layer by layer, and a toolpath is created to fill in the calculated intersection area for each level. Parallel and offset strategies are used to fill the intersection area.

Cladding 5D operation:

Cladding 5D allows you to build up a layer of material on the surface of a part using 3- or 5-axis machines. This is particularly useful when processing thin-walled models. The operation enables the surfacing of individual surfaces of the part with subsequent milling. Additionally, it can be used to harden surfaces by surfacing material in the most loaded areas of the component.