- June 9, 2023

- Posted by: admin

- Categories: General, MaxxCAM, Software

The cost of material is one of the most significant components of the overall production cost in the manufacturing industry. Automatic Nester is a system that assists you in creating nests with the least amount of waste. It will automatically generate all the necessary layouts so that you can focus on creating great products instead of spending hours manually editing nested sheets. In sheet metal fabrication, nesting software is a computer-aided design and manufacturing (CAD/CAM) program for designing, analyzing, and generating tool paths.

Using nesting software, the required quantities of individual parts are automatically arranged on sheets of stock material. Furthermore, it optimizes the cutting path and generates the NC code used to drive the CNC machine used to cut the material. It is important to consider the following factors when selecting sheet metal nesting software:

- The software should be accurate in order to produce accurate drawings in a short period of time.

- The software should have a wide range of features to accommodate a variety of needs.

- The user interface should be simple and intuitive to both new and experienced users.

The benefits of integrating MaxxCAM into your sheet metal production process

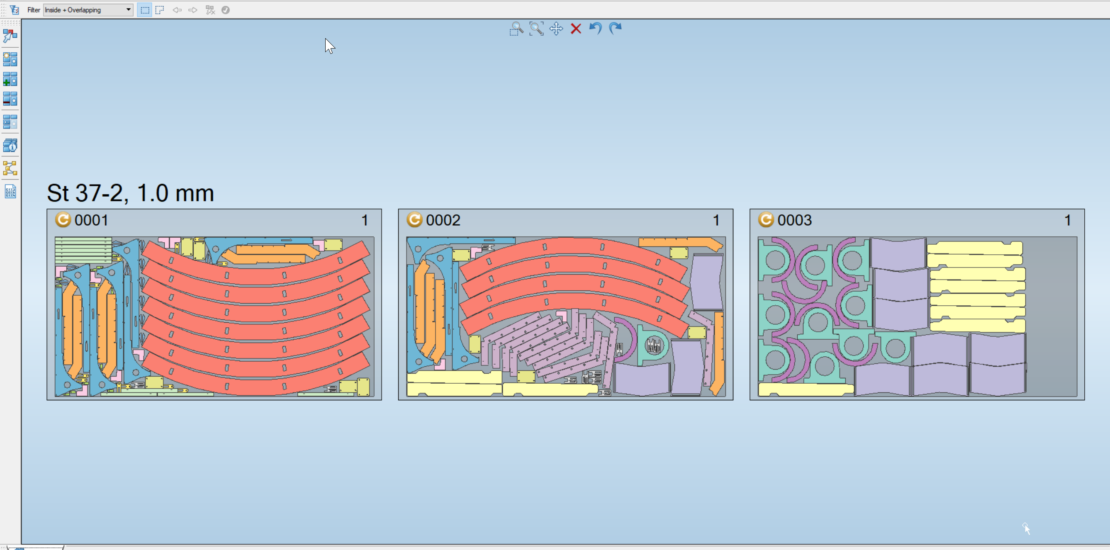

It is often difficult to find the most effective layout for cutting parts out of a given sheet with the least amount of waste material. MaxxCAM is a CAD/CAM and nesting software solution for laser, hybrid, plasma, and waterjet cutting. In addition to increasing productivity, it reduces material costs and helps companies increase efficiency. As a result of MaxxCAM’s innovative features and capabilities, coupled with its intuitive interface, it is both easy to use and cost-effective. In MaxxCAM’s nesting feature, a number of nesting algorithms are available to meet a variety of nesting needs.

Rectangular Nesting

Irregular Shape Nesting

MaxxCAM’s rectangular and Irregular nesting allow nesting on multiple sheets and sizes simultaneously, resulting in excellent results.

Nesting features:

- Rotation and grain control

- Nest for the next process

- Due date nesting

- Priority of parts

- Mirror of parts

- Revision of parts

- Nesting of parts and assemblies

- Comprehensive reports

- Colour code for easy part identification

- Use of multi-core processors for fast results

For more information about MaxxCAM Software and product inquiries, please contact us at https://nctools.com.au/service/maxxcam-software/ or call us on +61 3 8618 6884

If you are looking for more information you can read here https://www.maxxcam.com/