How to choose the right CNC software for your manufacturing needs

The CNC software used within the manufacturing industry is a computer-aided manufacturing (CAM) program. This system provides data that is used to control CNC machines and other production equipment. As a result of CNC software, technicians are able to perform machining tasks more efficiently while also developing an accessible interface. CNC machines such as mills, lathes, routers, and wire EDM are controlled by CAM software, which is used to program toolpaths and generate G-code. In addition to reducing waste of materials, increasing productivity, and improving quality and accuracy, CNC software offers many benefits to manufacturers. Factors that you should consider when choosing CNC software:

Here are 5 considerations you should have in mind.

- Do you have a budget in mind?

- What is the nature of your business?

- Are there any CAM or CAD packages included with this product?

- Do you know whether it is compatible with your machine and operating system?

- Do you have access to support if you need it?

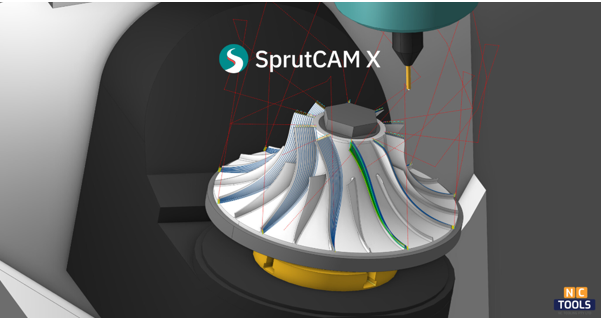

SprutCAM CAD CAM CNC Software

SprutCAM is a CAD/CAM system that generates NC programs for multi-axis milling, turning, turn/mill, wire EDM machines, and machining centers. It provides streamlined workflows and comprehensive functionality as well as significant benefits, such as faster time to market, increased productivity, workflow optimization, and infinite repeatability.

Features that help you program your CNC Machines :

- The interface of SprutCAM is very user-friendly and organized into four main modes: 3D model, 2-D geometry, Machining, and Simulation.

- It is capable of importing and transforming 2D and 3D geometric models prepared in any CAD system.

- The built-in 2D parametric drafting tools provide the ability to create objects in any plane, which can be referenced to the coordinates of a 3D model.

- The machining process can be easily configured and consists of a series of options that are selected by the user from a comprehensive list. Within each operation, the user selects the parameters that should be applied. This includes the type of cutting tool, its dimensions, the cutting speed, etc.

- The toolpath for the first machining cycle is generated from the start workpiece. Following this, the form of the workpiece is updated. Therefore, the next cycle generates its own toolpath based on the updated workpiece.

- Simulation: The user can view exactly how the part is going to be machined, either in a step-by-step or variable speed continuous mode.

- Postprocessor: This feature generates an NC program in accordance with the user’s machine or CNC system once the machining cycle has been accepted. Aside from the extensive list of available Posts, N C Tools with their industry experience can develop Posts according to the user’s requirements. The user also has the option of generating new posts or modifying existing ones by using the provided <Postprocessors generator >.

NC Tools is the Australian and New Zealand distributor for SprutCAM. For more information about SprutCAM Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884