Factors Affecting the Cost of Laser Cutting

Laser cutting is a technology that uses a high-powered laser beam to cut materials with a high degree of precision and accuracy. Due to its ability to produce high-quality cuts quickly and efficiently, it has become a popular choice for manufacturing and fabrication industries. It is important to note, however, that the cost of laser cutting can vary depending on several factors.

It is important to note that the type of material being cut plays a significant role in determining the cost of laser cutting. Different materials require different laser types and power levels, which can affect the cost. Metals such as steel and Aluminium require higher laser power, which can increase the cost.

The thickness of the material can also influence the cost of laser cutting. Generally, the thicker the material, the more laser power is required to cut through it. As a consequence, the service can be more expensive.

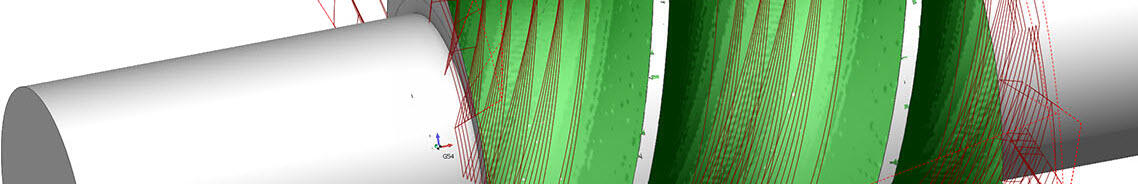

It is also important to consider the complexity of the design when determining the cost of laser cutting. A complex design may require more time and effort to program the laser and set up the cutting process, which may increase the cost of the service. Furthermore, designs requiring multiple cuts or intricate shapes may require multiple laser passes, which can also increase the cost.

Laser cutting costs can also be affected by the size of the project. In addition, larger projects require more time and materials, which can result in an increase in the cost of the service. However, some laser cutting service providers offer discounts for larger orders, so it is important to check with them to find out if this is an option.

Lastly, the location of the laser cutting service provider may affect the cost of the service. There may be a difference in price based on the region, and some providers may charge a higher shipping or handling fee.

In general, laser cutting services can range from a few dollars for a small, simple project to several thousand dollars for a larger, more complicated project. It is important to note, however, that these are only rough estimates, and the final cost will depend on the specifics of the project.

In conclusion, the cost of laser cutting depends on a variety of factors, including the material to be cut, the thickness of the material, the complexity of the design, the size of the project, and the location of the service provider.

We have gained a better understanding of operating a laser cutting shop through our experience working in the manufacturing industry. It is more important than ever that you are able to provide your customers with a fast, accurate, and competitive quote now that they are sourcing parts from local companies.

A smart quotation software that helps you win more laser cutting jobs, increase profits and secure more clients. Setup is simple and on-demand support is included.

Perfect for 2D profile cutting, including plasma, laser, oxyfuel, and waterjet.

https://www.youtube.com/watch?v=pNf442p5NBo

For more information about SmartQuote Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884