SprutCAM 5 axis machining and how it can benefit your business

5-axis refers to a machine’s ability to move a tool in five directions at once. The main benefit of 5-axis machining is that it is able to produce complex shapes using a single setup. SprutCAM generates toolpaths for 5-axis milling machines from machine kinematics and the parameters of the user control. In 5-axis machining, there are three linear axes and two rotational axes. The generated toolpath contains commands for positioning the XYZ axes of the machine (GOTO, CIRCLE, etc), as well as commands for positioning the machine rotary axes (MULTIGOTO). As a result, the rotary coordinates are the actual positions of the corresponding machine axes, while the linear coordinates are the position of the tooling point in relation to a coordinate system of the workpiece. Two control modes are available for SprutCAM 5-axis machining.

Those are the default “3-axis” mode and the “Tool Centre Point Management (TCPM)” mode. Controlling behavior can be selected from three options.

• Does the tooling point rotate along with the tool head rotation, or does it remain stationary?

• Do the workpiece zero point (G54) rotate with the rotary table, or do they remain stationary.

• Are the axes of the coordinate system of the workpiece rotating with the rotary table, or are they fixed?

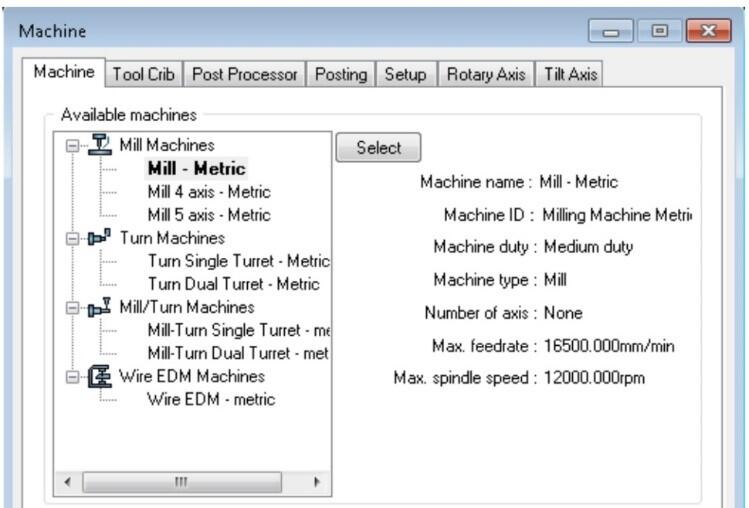

Both options are available in SprutCAM under the Control Data section of the machine configuration file and the Control Parameters section of the machine properties inspector.

In the TCPM mode, all three 5 axis compensation options are available. As a result, the five-axis toolpath can be generated independently of the machine kinematics, the workpiece setup, and the tool length. Most of the controls in the default “3 Axis” mode are disabled for all three 5-axis compensation options. So they behave as regular 3-axis controls, without any knowledge of the kinematics of the machine.

Strategies for toolpath control

• parallel to horizontal plane

• parallel to vertical plane

• parallel to 3D plane

• parallel to curve

• across curve

• morph between two curves

• morph between two faces

• around rotary axis

Strategies for tool axis control

• normal to surface

• flank

• fixed

• to rotary axis

• through the point

• through the curve

• perpendicular to the toolpath

For more information about Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884