Your advanced manufacturing process requires advanced CAD CAM software

Advanced CAD CAM

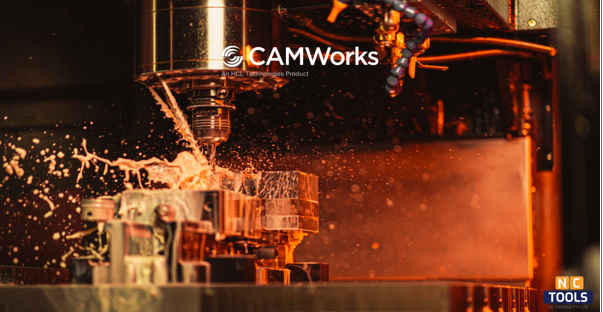

The use of computer numerical control (CNC) machines in manufacturing have made a significant contribution to the industry. Automation has enabled the machining process to be automated while still being flexible enough to accommodate small to medium-sized batches in part production. The functions of CNC machines are controlled by software. A computer-aided design (CAD) and computer-aided manufacturing (CAM) software program is known as Advanced CAD CAM.

Computer-aided design (CAD) is a method of creating 2D or 3D computer models based on common geometric patterns, as opposed to computer-aided manufacturing (CAM), which uses the geometry in the CAD files as input for programming the machines.

As a result of CAD/CAM integration and CNC, the machining process becomes simpler and more convenient. In particular, 3D visualization and simulation in CAD/CAM software significantly reduce the design time and enable earlier identification of errors in the practical CNC machining process.

The following benefits can be derived from the use of Advanced CAD CAM software in CNC machining:

The use of Advanced CAD CAM software provides a great deal of flexibility in the design process. The software makes it easy for users to make small changes. In addition to simulating the design behavior, the software allows users to analyze the results.

It allows a manufacturer to visually inspect the machining process using the simulation feature. As a result, tool gauges and collisions can be captured at an early stage. A feature such as this contributes to the overall productivity of the manufacturing setup. In addition, it reduces material waste and eliminates errors.

In Advanced CAD CAM applications, tool paths are created at high speeds, which allows machinists to make deeper cuts at higher speeds. Using these high-speed toolpaths, cycle times can be reduced by at least 70%.

CAD-CAM software simplifies and streamlines the manufacturing process, thereby reducing the effort required to plan and allocate production tasks.

CNC machines are able to operate autonomously as a result of Advanced CAD CAM ntegration, thus increasing their efficiency and productivity.

In the past, many CNC machine shops avoided machining in five and four axes. They are now able to do so more easily due to the development of advanced Multiaxis CAM technology. Several surface-based machining operations can be performed with advanced 5-axis toolpaths, such as 3+2 programming, part milling, etc. As a result, advanced CAM systems are capable of providing 5-axis and 4-axis simulation, which is of particular importance when machining complex parts.

For more information about CAMWorks Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884

More info at www.camworks.com