Why Turret Punching Remains Essential in Sheet Metal Fabrication

Why Turret Punching Remains Essential in Sheet Metal Fabrication

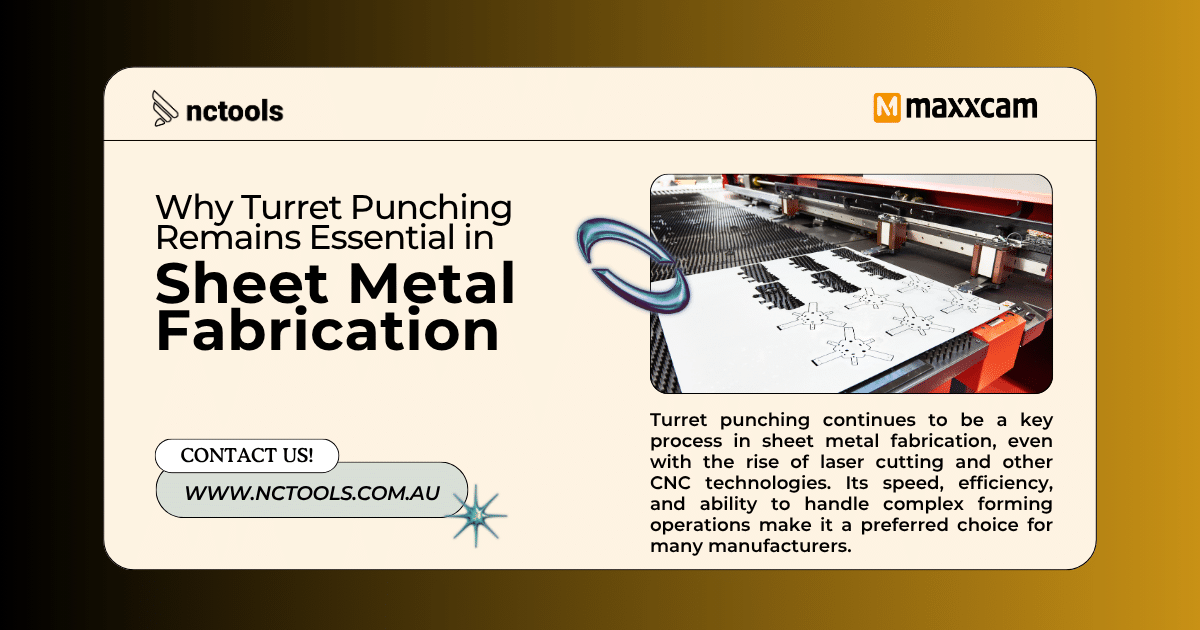

Turret punching continues to be a key process in sheet metal fabrication, even with the rise of laser cutting and other CNC technologies. Its speed, efficiency, and ability to handle complex forming operations make it a preferred choice for many manufacturers. Unlike laser cutting, turret punching not only cuts sheet metal but also creates features like dimples, louvers, and countersinks without requiring secondary processes.

Speed and Efficiency in High-Volume Production

Turret punch presses are highly efficient for jobs requiring repetitive patterns, such as perforated panels or control enclosures. The ability to rapidly process parts with multiple holes, cutouts, or formed features makes turret punching well-suited for mass production. Compared to laser cutting, which requires continuous movement of the cutting head, turret punching executes these tasks in a fraction of the time by using dedicated tooling.

Cost-Effectiveness and Lower Operational Costs

For many applications, turret punching offers a more economical solution than laser cutting. Punch tooling allows manufacturers to create forms, extrusions, and cutouts in a single process, eliminating the need for expensive secondary operations. Additionally, turret punch presses have lower operational costs as they do not require consumables such as laser optics or assist gases. The durability of punch tooling, which lasts for thousands of cycles, further contributes to reduced long-term expenses.

Versatility in Sheet Metal Forming

Unlike laser cutting, which is primarily used for profiling, turret punching supports forming operations, including louvers, extrusions, and knockouts. This capability allows manufacturers to create complex features directly within the turret punch press, improving overall efficiency and reducing handling time. The ability to combine cutting and forming in one process makes turret punching ideal for industries requiring ventilation panels, electrical enclosures, and structural components.

Durability and Consistency

Turret punch presses are built for durability and require less maintenance compared to laser machines. Since the cutting and forming operations rely on mechanical tooling rather than high-energy beams, maintenance costs are lower, and machines can run for extended periods with minimal downtime. Consistency is another key advantage, as turret punch presses deliver repeatable results across large production runs, ensuring uniformity in part dimensions and quality.

Enhancing Turret Punching with CAD/CAM Software

Although turret punching offers several advantages, its efficiency largely depends on how well the process is programmed and optimised. This is where CAD/CAM solutions like MAXXCAM play a crucial role. By automating tool selection, nesting, and programming, MAXXCAM helps manufacturers maximize material utilisation and reduce setup time. With intelligent nesting algorithms and feature recognition, turret punch programming becomes faster and more precise, allowing businesses to get the most out of their equipment.

Despite advancements in other technologies, turret punching remains a crucial process in sheet metal manufacturing due to its speed, versatility, and cost advantages. With the right software tools, manufacturers can further improve efficiency and maintain a competitive edge in high-volume production.

For more information about Smart cut Quote Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884

Or Visit https://smartcutquote.com/