The Importance of Good Nesting Software in the Laser Cutting Industry

The Importance of Good Nesting Software in the Laser Cutting Industry

With technological advancements and the growing affordability of fibre laser machines, even small businesses can now access powerful tools that were once reserved for large manufacturers. However, many of these machines come bundled with generic nesting software, often prioritizing basic functionality over efficiency. This raises a critical question: Can your business afford the inefficiencies of subpar nesting software?

Why Nesting Software Matters

Nesting software is a vital component of any laser cutting operation, dictating how parts are arranged on raw material for cutting. Efficient nesting ensures:

- Minimal Material Waste: Poorly optimized layouts lead to higher material usage, directly impacting costs.

- Reduced Cutting Time: Inefficient nesting increases machine run time, lowering overall productivity.

- Improved Consistency: Reliable software creates repeatable, precise layouts, ensuring consistent quality.

For small businesses, where margins are often tight, the right nesting software can make the difference between profitability and loss.

Challenges with Generic Nesting Software

The nesting software included with many machines may lack advanced optimization algorithms. While these tools might suffice for simple tasks, they often struggle with complex designs or material constraints, resulting in:

- Significant material wastage.

- Increased processing time.

- Difficulty in handling intricate shapes and multiple materials.

In a competitive market, especially with the rise of global manufacturers, such inefficiencies can put businesses at a disadvantage.

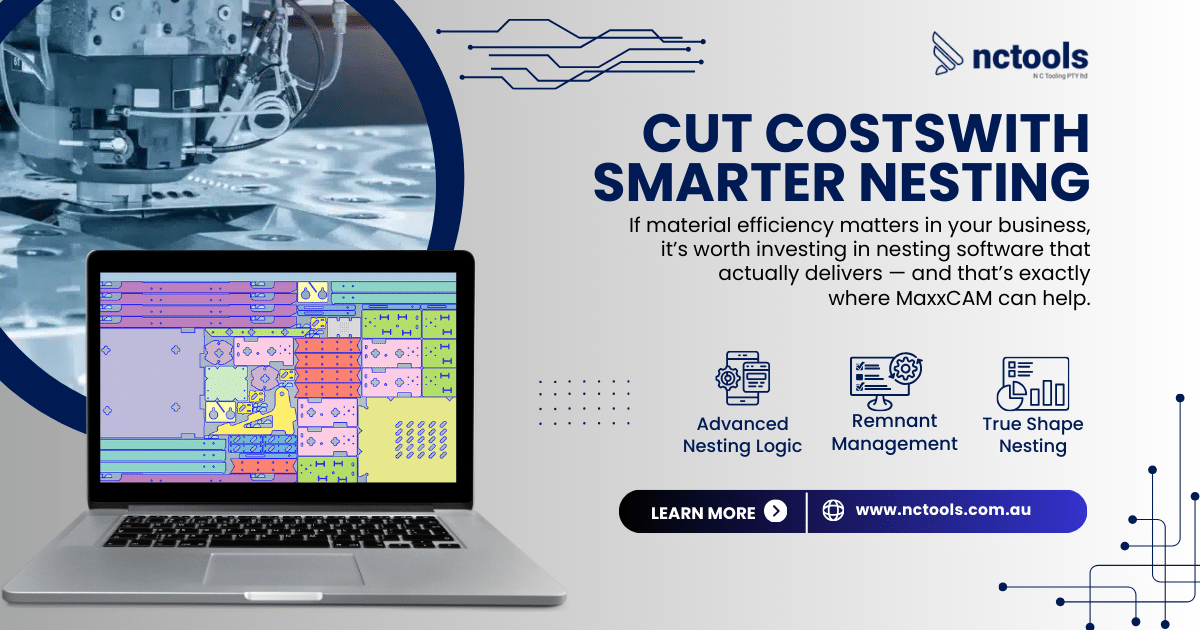

How MaxxCAM Software Stands Out

MaxxCAM leverages cutting-edge technology and advanced algorithms to deliver unparalleled nesting efficiency. Here’s how it benefits your business:

- Intelligent Layouts: MaxxCAM uses sophisticated algorithms to arrange parts with maximum efficiency, minimizing unused material.

- Adaptive Strategies: Whether working with various materials, thicknesses, or complex shapes, MaxxCAM adjusts its nesting strategy to deliver the best results.

- Reduced Processing Time: By optimizing cut paths and minimizing machine movements, MaxxCAM shortens production cycles, saving valuable time.

- Material Savings: Smart nesting not only reduces waste but also enables businesses to save on raw material costs significantly.

- Cost Efficiency: With faster processing and less waste, MaxxCAM ensures a rapid return on investment, making it ideal for small and large operations alike.

Investing in the Future

In today’s competitive environment, businesses cannot afford to overlook the role of efficient nesting software. MaxxCAM not only empowers small businesses to maximize their fibre laser’s potential but also helps them stay competitive by reducing costs and improving productivity.

Choosing MaxxCAM is more than upgrading your software—it’s an investment in material savings, time efficiency, and the future of your business.

For more information about Smart cut Quote Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 6884

Or Visit https://smartcutquote.com/