Subtractive Machining processes: Milling, Turning, Mill-Turn

Managing production with close tolerance and high accuracy is a challenging task for the manufacturing industry. It is primarily used for machining projects that require high precision and complexity. In subtractive manufacturing, the material is removed to create parts, while in additive manufacturing, the material is added layer by layer to create objects. By subtractive manufacturing/machining processes, such as milling, turning, and mill-turning, parts are produced by removing unnecessary material. CAMWorks is an integrated cam solution that supports all CNC machining processes.

Subtractive manufacturing has the following advantages:

- It can produce accurate results

- A wide range of materials can be processed

- Subtractive manufacturing is more suitable for large-scale productions

- Excellent dimensional control and surface finish

- The processes are faster

Milling:

One of the most commonly used process for machining parts is milling. The process involves feeding the work against a rotating multipoint cutter in order to remove material. These systems generally have three degrees of freedom. While the workpiece remains stationary, they are free to move around the X, Y, and Z axes. CAMWorks Mill features can be identified by Automatic Feature Recognition (AFR) and defined using Interactive Feature Recognition (IFR) for Y-axis milling on the OD and face of the part. The CAMWorks machining module offers 2.5 Axis, 3 Axis, 4 Axis with undercut, 4 Axis, and 5 Axis simultaneous milling, as well as rotary milling.

- 5 axis milling includes automatic roughing and finishing, thread milling, face milling, and single-point milling.

- A 3-axis cycle is developed for speed, accuracy, and efficient memory usage.

- With 4/5 axis milling, the user can create toolpaths across complex shapes that could not be machined with a 3-axis machine.

Turning:

A machining operation is performed on a lathe in which the workpiece rotates at high speeds while a cutting tool is fixed to remove material. Turning can be used to create cylindrical parts. CAMWorks 2 and 4 axis turning include automatic roughing, finishing, grooving, threading, cutting, and single point (drilling, boring, reaming, and tapping) cycles. Cutting with CAMWorks is fast and error-free. Turn features on the OD or ID of the part, front face, and groove are found by AFR or inserted interactively using IFR.

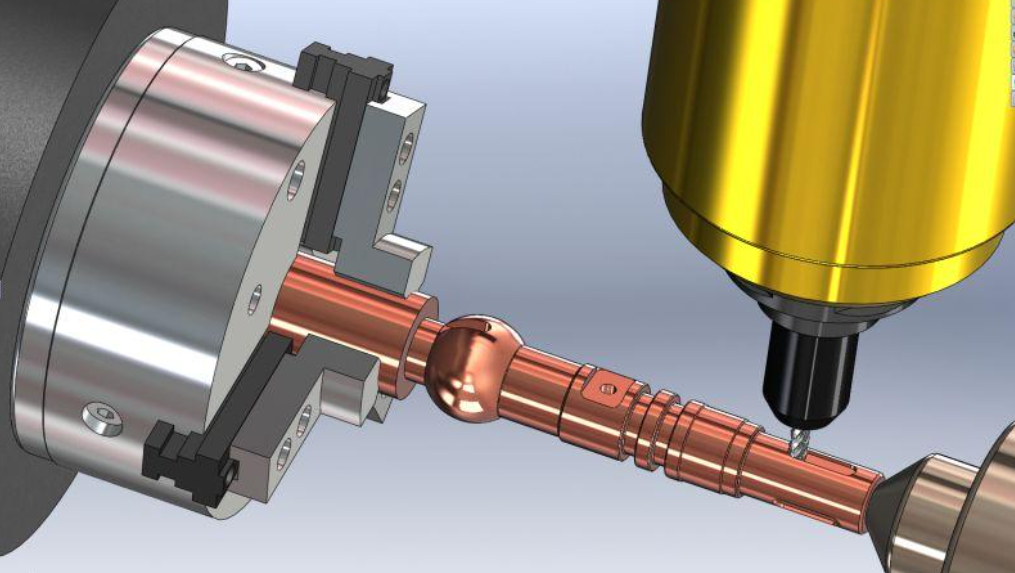

Mill-Turn:

A Mill-Turn is essentially a combination of a mill and a lathe. A Mill-Turn machine is capable of machining both turning and milling operations in a single setup device, allowing complex operations to be completed faster and more accurately.

Benefits of using CAMWorks Mill-Turn:

- Reduce programming time

- Improve quality

- Automate the CNC programming process

- Reduce setup time

For more information about Mill-Turn visit: https://nctools.com.au/product/camworks-mill-turn/