SprutCAM X Robot plays a crucial role in the operation’s success

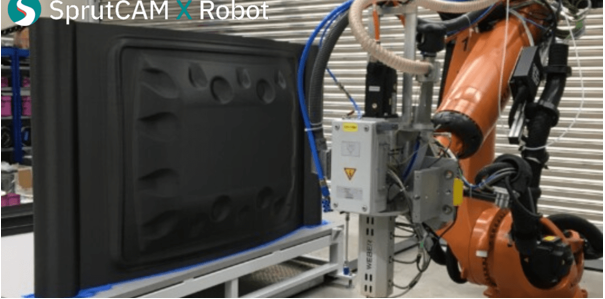

A German automobile manufacturer has selected SprutCAM X Robot (at BMW Group’s Landshut plant) to carry out 3D printing with KUKA robots, demonstrating the software’s versatility and capabilities in additive manufacturing. A powerful solution for large format 3D printing applications can be achieved by combining SprutCAM X Robot and KUKA robots. A brief overview of how the SprutCAM Robot module can contribute to large-format 3D printing follows:

- Advanced Robotic Programming: The SprutCAM Robot module provides intuitive tools and features for programming robot movements and actions. An easy-to-use interface allows operators to define toolpaths, layering strategies, and deposition patterns required for large format 3D printing. It supports a variety of robot types, including multi-axis industrial robots such as KUKA, enabling the printing of precise and complex documents.

- User-configurable printing parameters: The SprutCAM Robot module enables users to configure printing parameters specific to large format 3D printing. Layer height, nozzle size, infill patterns, support structures, and other critical parameters are included in this setting. These settings can be fine-tuned to achieve optimal print quality, strength, and efficiency for specific applications.

- SprutCAM’ s advanced simulation capabilities are essential in the production of large format 3D models. Users of the software can simulate the entire printing process, including robot movements, material deposition, and interaction with the workpiece. As a result of this simulation, collisions can be identified and prevented, the print quality can be assessed, and the printing parameters can be optimized prior to the actual printing process. By visualizing and optimizing the process, errors can be minimized, material waste can be reduced, and overall efficiency can be increased.

- SprutCAM Robot module supports adaptive printing strategies, which are particularly useful in large format 3D printing. Based on real-time feedback from the printing process, these strategies allow the robot to dynamically adjust its movements and parameters. As a result, layers are deposition consistently, workpiece variations are compensated for, and the quality of the print is improved overall.

- It is common for large-format 3D prints to require post-processing and finishing operations. As part of the SprutCAM Robot module, additional functionality is available, including the generation of toolpaths for post-processing operations such as machining, sanding, and polishing. This enables operators to finish printed parts precisely, achieving the desired surface quality and dimensional accuracy.

In collaboration with Datentechnik Reitz, the renowned Bavarian automobile manufacturer selected SprutCAM X Robot for large format 3D printing. This demonstrates the software’s capabilities in additive manufacturing. Combining SprutCAM Robot with KUKA robots leads to high-quality and efficient large format 3D printing through advanced robotic programming, simulation, optimization, and adaptive strategies. With this combination, printing processes can be controlled precisely, resulting in superior results for a variety of automotive and manufacturing applications.

Datentechnik Reitz GmbH & Co. KG. www.cnc-technik.de

Australia and New Zealand customers contact https://nctools.com.au/