Advantages of Solidworks CAM/CAMWorks for CNC Manufacturing

Advantages of Solidworks CAM/CAMWorks:

CNC (Computer Numerical Control) machining processes rely heavily on CAM (Computer-Aided Manufacturing) software. CAD (Computer-Aided Design) software such as Solidworks is typically used to convert digital 3D models into toolpaths and instructions for CNC machines to use in producing desired parts or products. Solidworks integrated CAM (Solidworks CAM / CAMWorks) offers many advantages over standalone CAM software:

Automation and Efficiency:

By automating toolpath generation, CAM software saves a significant amount of time and reduces the possibility of human error. Through the integration of CAM within CAD environments, such as Solidworks, users can seamlessly move from design to manufacturing without having to export/import files. As a result of this integration, the workflow is streamlined and more efficient.

Design-Process Synchronisation:

The integration of CAD and CAM, such as Solidworks CAM or CAMWorks, promotes real-time collaboration between designers and manufacturers by eliminating the risk of data loss or misinterpretation.

Consistency and Accuracy:

The use of integrated CAM software ensures that the design intent is accurately preserved during the manufacturing process. CAM can access all geometric and assembly information directly when integrated with the same CAD platform, resulting in more precise and consistent machining results.

Machinability Analysis:

A CAM software package integrated with a CAD model can perform machinability analyses, helping designers and engineers identify potential problems during manufacturing. In addition to reducing production delays and costs, this information can be used to make design adjustments early in the process.

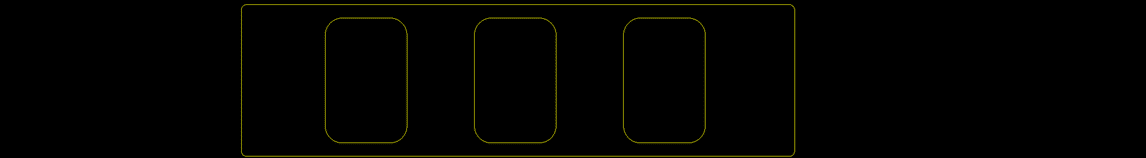

Post-Processing:

CNC machines require specific instructions (G-codes and M-codes) in order to operate. CAM systems with integrated post-processing capabilities, such as Solidworks CAM or CAMWorks, are usually preconfigured for various CNC machines. In addition to ensuring compatibility, this feature reduces the possibility of post-processing errors.

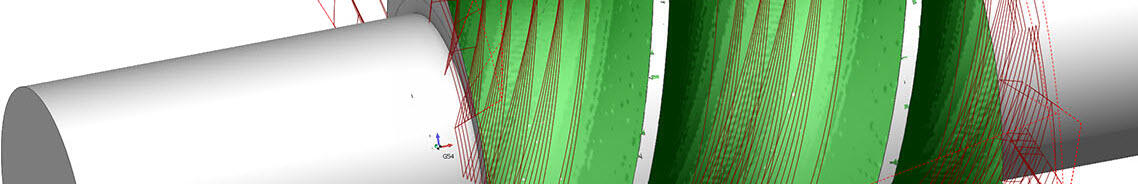

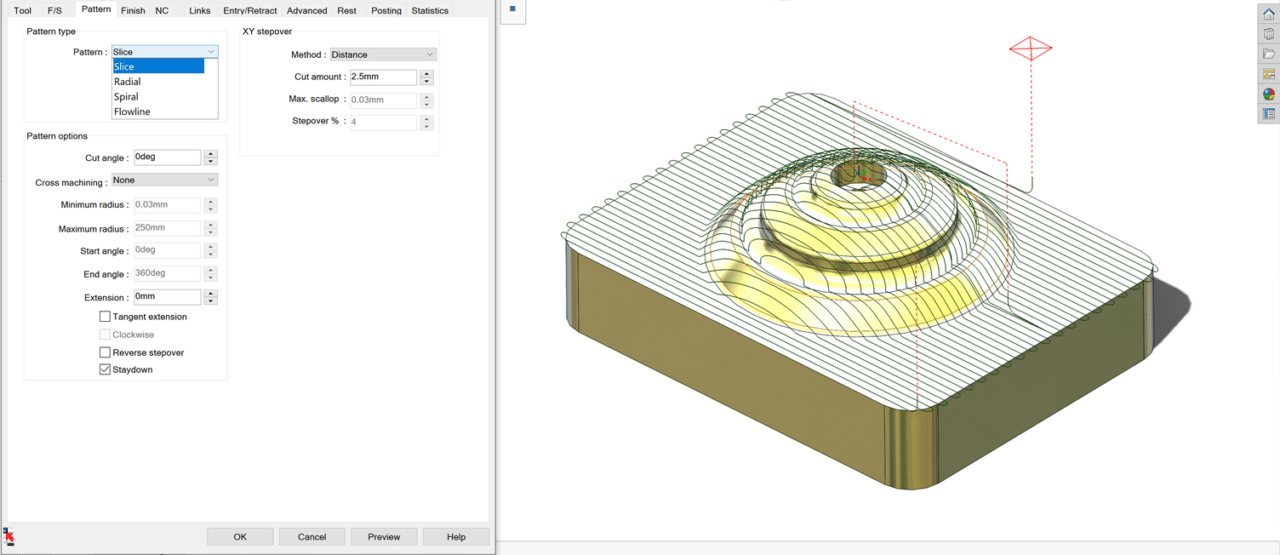

Toolpath Optimization:

CAM software optimizes toolpaths to maximize efficiency, reduce machining time, and extend tool life. Having high-quality results while minimizing production costs is crucial for complex parts with intricate geometries.

Simulations and Visualisation:

With CAM integrated with CAD software, users can simulate the machining process before cutting the material. Simulation assists in identifying potential problems, such as collisions, excessive material removal, or tool interference, allowing adjustments to be made before production is initiated.

Using integrated CAM software like Solidworks CAM or CAMWorks within the Solidworks CAD environment provides a seamless and efficient workflow, improved design-process synchronization, increased accuracy, and the ability to optimize machining operations. In CNC machining processes, these benefits contribute to the reduction of production time, the reduction of costs, and the improvement of product quality.

Get in touch with N C Tools, your local experts in CAM solutions

For more information on Advantages of Solidworks CAM/CAMWorks that can add value to your business please visit https://nctools.com.au/ or call us on +61 3 8618 6884

See more info on Advantages of Solidworks CAM/CAMWorks here CAMWorks