Does excel work well for estimating laser cutting costs or is it better to utilize dedicated software ?

Does Excel work well for estimating In the manufacturing industry?, laser-cutting cost estimation is an important part of the process, as it enables manufacturers to determine the cost of producing a part or product by using laser-cutting technology. Although Excel can be used to estimate laser cutting costs, dedicated software offers several advantages over Excel.

Specialized Features:

Laser-cutting cost estimation software is designed specifically for this purpose, so it offers specialized features and tools to improve accuracy and efficiency. Material and labour costs, as well as other expenses, can be automatically calculated using these features. In some software packages, advanced features such as ERP integration, real-time job cost tracking, and automated quote generation are offered.

Accuracy:

In order to estimate laser cutting costs accurately, dedicated software takes into account factors such as material costs, cutting time, and machine usage. By doing so, manufacturers will be able to make more informed decisions regarding pricing and profitability. Cost estimation accuracy is of particular importance to manufacturers with tight margins or low-volume production runs, where even small errors in estimation can have a significant impact on profitability.

Integration:

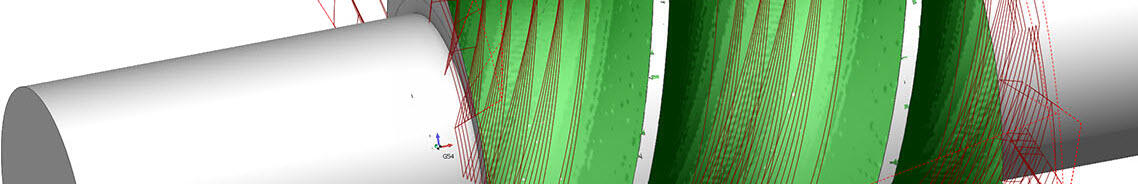

To provide a more seamless workflow, many dedicated laser cutting software packages can be integrated with CAD and CAM software. As a result, the entire process, from design to final production, can be simplified. Additionally, integrating different departments or software programs may reduce the likelihood of errors or miscommunications.

Customization:

Dedicated software packages often provide users with the option of customizing calculations and settings according to their specific needs and workflows. A customized cost estimation process can help ensure that the manufacturer’s needs are met. Moreover, customizing can reduce the risk of errors by eliminating steps that are irrelevant to a particular project.

Time Savings:

The use of dedicated software for estimating laser cutting costs can be more efficient than using Excel, as many of the calculations can be performed automatically by the software. As a result, time can be freed up for other tasks, such as design and production. It is also possible to generate a cost estimate more quickly using some software packages by using features such as templates and presets.

To summarize, although Excel can be used for laser-cutting cost estimation, dedicated software offers several advantages, including specialized features, accuracy, integration, customization, and time savings. For manufacturers who wish to optimize their laser cutting operations and increase their profitability, dedicated software for cost estimation should be considered.

Smart Cut Quote is a software designed for laser cutting businesses to streamline the quoting process, providing accurate quotes in minutes.

https://www.youtube.com/watch?v=wtKOS2txXEE

here is an example https://eagle-group.eu/en/example-calculation

For more information about SmartQuote Software and product inquiries, please contact us at https://nctools.com.au/ or call us on +61 3 8618 68